Qashqai J11. Transaxle & Transmission - part 6

TM-82

< REMOVAL AND INSTALLATION >

[6MT: RS6F95R]

DIFFERENTIAL OUTPUT SEAL

REMOVAL AND INSTALLATION

DIFFERENTIAL OUTPUT SEAL

Exploded View

INFOID:0000000010428775

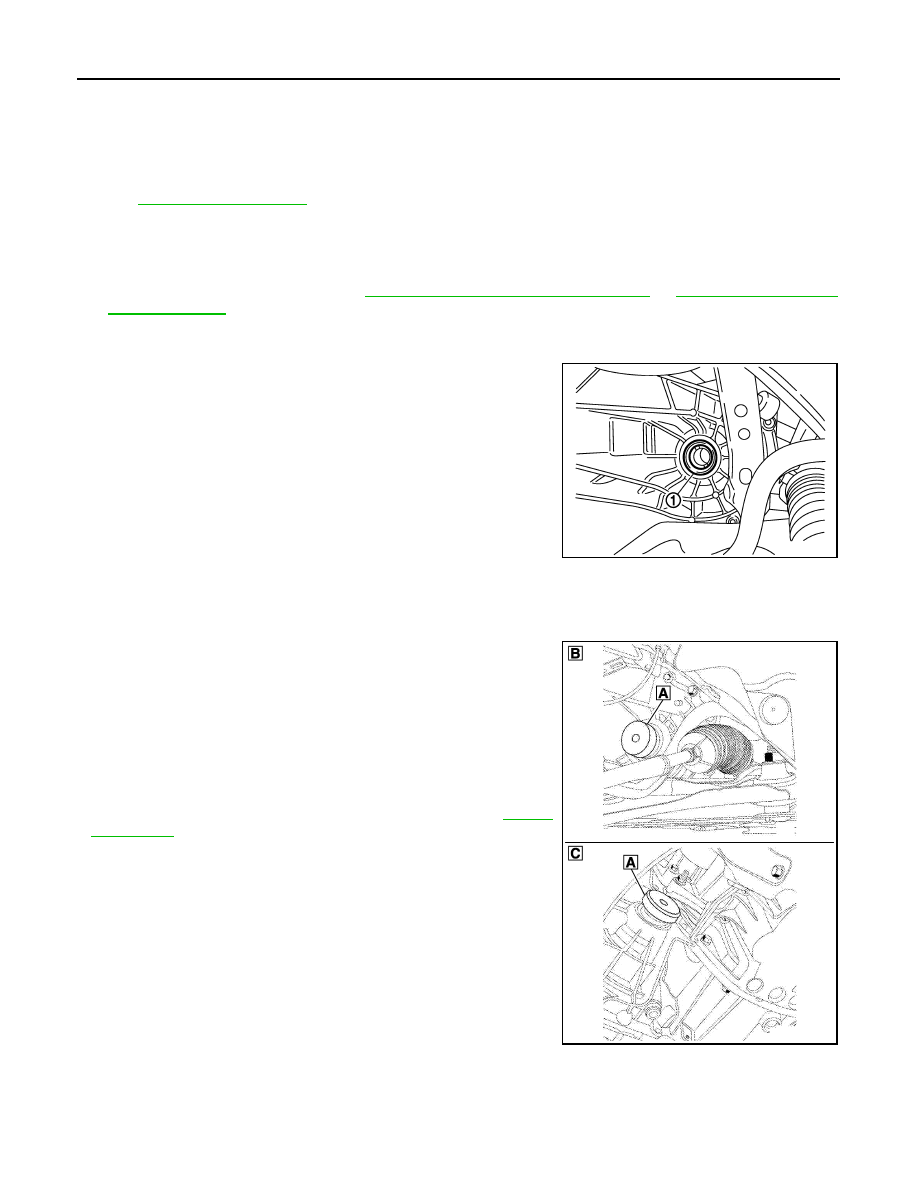

.

Removal and Installation

INFOID:0000000010428776

REMOVAL

1.

Remove front drive shafts. Refer to

FAX-22, "Removal and Installation (LH)"

2.

Tap the base of the differential output seal using a roll pin punch and a small hammer to rotate it in its

housing.

3.

Remove differential output seals (1) using pliers, taking care not

to damage the splines.

CAUTION:

Never damage transaxle case and clutch housing.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Lubricate differential output seals before installing

• Install differential output seals (1) to clutch housing and transaxle

case using the drift (A) [SST: Bvi. 1689].

CAUTION:

• Never reuse differential side oil seal.

• When installing, never incline differential output seals.

• Never damage clutch housing and transaxle case.

• Check oil level and oil leakage after installation. Refer to

SCIA7625E

B

: Transaxle case side

C

: Clutch housing side

E1DIA0341ZZ