Mitsubishi Outlander (2013+). Manual - part 574

Rear wiper motor removal steps

4.

Cover

>>

B

<<

5.

Rear wiper arm assembly

•

Tailgate trim (Refer to GROUP 52A,

Tailgate Trim )

6.

Grommet

7.

Rear wiper motor assembly

8.

Rear wiper motor bracket

Rear washer hose removal steps

•

Front/rear scuff plate, cowl side

trim, quarter trim (Refer to GROUP

52A, Interior Trim )

•

Tailgate trim (Refer to GROUP 52A,

Tailgate Trim )

9.

Rear washer hose

REAR WIPER AND WASHER

EXTERIOR

51-55

NOTE: For removal and installation of the wiper and

washer switch, refer to GROUP 54A, Column Switch

.

INSTALLATION SERVICE POINTS

>>A<< REAR WIPER BLADE INSTALLA-

TION

AC101090

AE

A

A

Wiper blade

Backing

Backing

Section A – A

Wiper

blade

Backing

CAUTION

Use a curved backing like that shown for the

backing of a wiper blade to ensure sustained

wiper wiping performance.

>>B<< REAR WIPER ARM AND BLADE

ASSEMBLY INSTALLATION

ACB05700 AB

Rear wiper arm and

blade assembly

(A)

Assemble the wiper blade so that their edge stops at

the specified position.

Standard value:

(A):

φ 2 marking ± 5 mm

INSPECTION

M1511019103696

REAR WIPER MOTOR CHECK

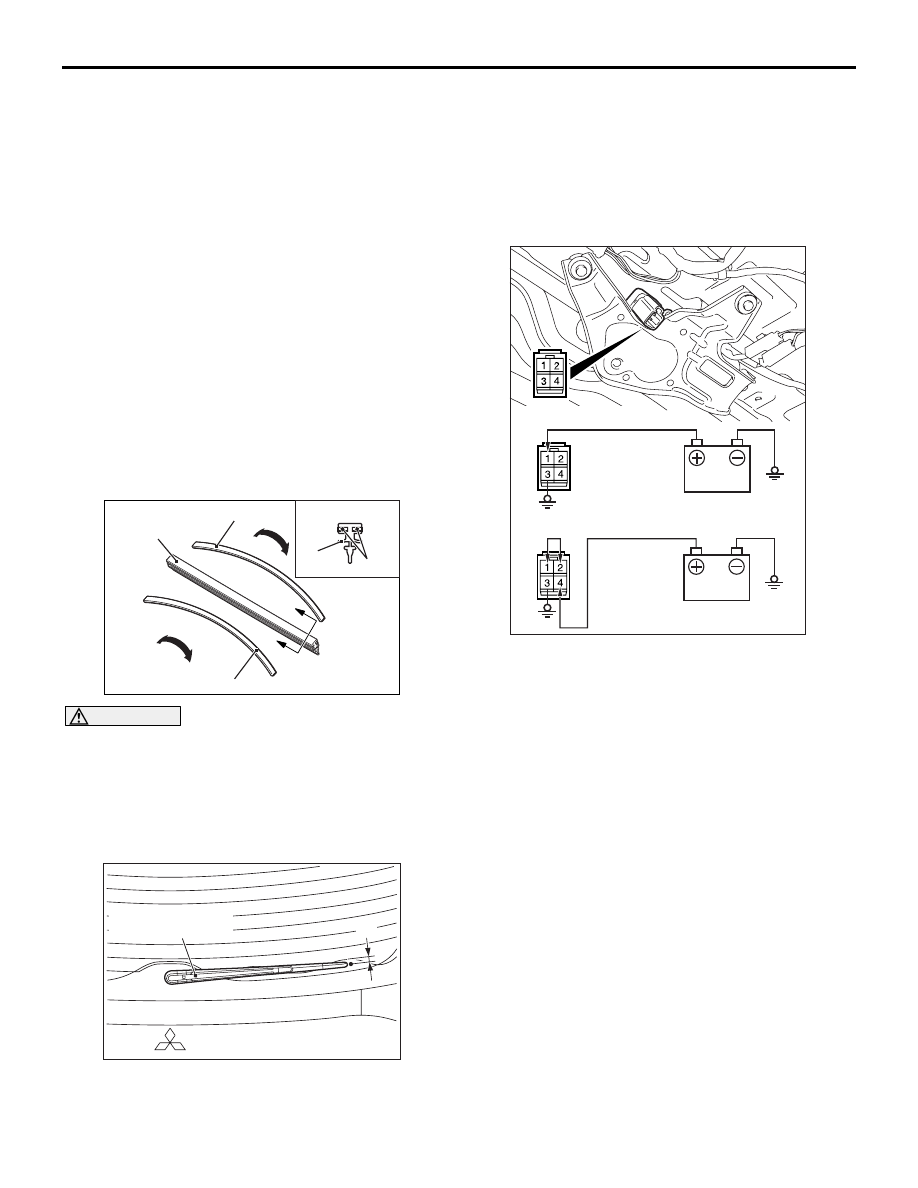

AC103246

AC506678

AB

Operation check

Stop position check

Inspect the rear wiper motor by disconnecting the

harness connector with the motor attached to the

vehicle.

REAR WIPER MOTOR OPERATION

CHECK

Connect the battery to the rear wiper motor to

inspect the motor operation as shown in the illustra-

tion.

REAR WIPER MOTOR STOP POSITION

CHECK

1. Connect the battery to the rear wiper motor as

shown in the illustration.

2. Disconnect the battery in the middle of the motor

rotation and check to see that the motor stops.

3. Reconnect the battery.

4. Check to see that the rear wiper motor runs and

then stops at the automatic stop position.