Content .. 1520 1521 1522 1523 ..

Mitsubishi Galant 9G. Manual - part 1522

POWER STEERING GEAR BOX AND LINKAGE

TSB Revision

POWER STEERING

37-38

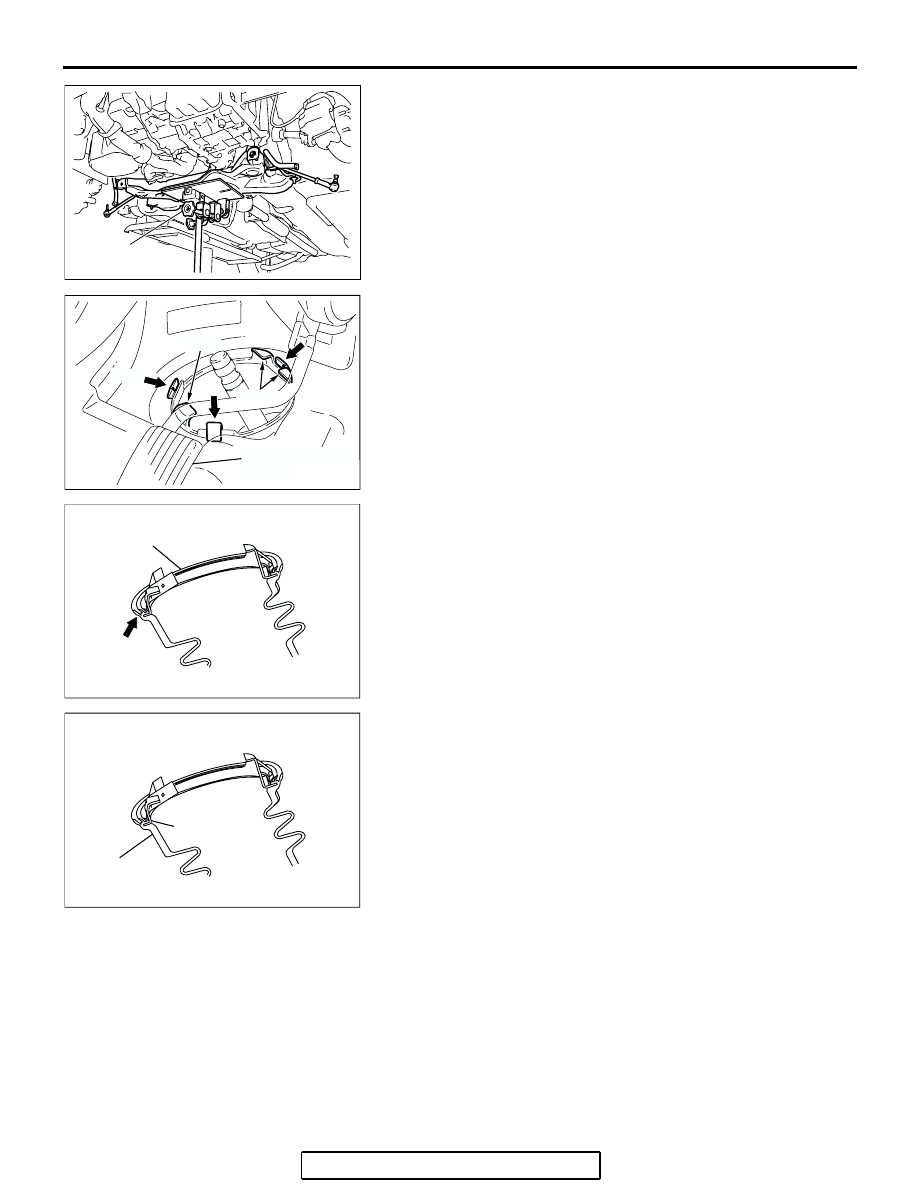

2. Use a transmission jack to lift the crossmember assembly.

3. From inside the vehicle, pull tab A and then tab B to secure

the three clips to the body panel.

NOTE:

When securing the steering column dash panel

cover to the body panel, be careful that the seal lip does not

move backwards.

4. Check that it has been secured by pressing down the tip of

the clips by your finger. Also check that the steering column

dash panel cover is installed securely to the steering gear.

5. After installing the steering column dash panel cover, check

that the steering column dash panel cover rubber is not

disengaged from the retainer. If there is any doubt, release

the clips from the body, engage the rubber again and

reinstall to the body.

6. Tighten the crossmember mounting nuts and bolts.

.

AC206593

AC306696

TRANSMISSION

JACK

AB

AC306790 AC

ACCELERATOR

PEDAL

CLIP

TAB A

TAB B

AC308270 AB

SEAL RIP

STEERING COLUMN

DASH PANEL COVER

AC308270 AC

RUBBER

RETAINER