Mitsubishi Evolution X. Manual - part 814

ON-VEHICLE SERVICE

TSB Revision

ACTIVE SKID CONTROL SYSTEM (ASC)

35C-263

ON-VEHICLE SERVICE

HYDRAULIC UNIT CHECK

M1355006100138

Required Special Tools:

• MB991958: M.U.T.-III Sub Assembly

• MB991824: Vehicle Communication Interface (V.C.I.)

• MB991827: M.U.T.-III USB Cable

• MB991910: M.U.T.-III Main Harness A (Vehicles with

CAN communication system)

1. Raise the vehicle using a jack and support the specified

points with a rigid rack.

CAUTION

Before connecting or disconnecting scan tool, always turn

the ignition switch to the LOCK (OFF) position.

2. Before setting scan tool, turn the ignition key to the LOCK

(OFF) position.

3. With the M/T vehicles, check that the shift lever is in the

neutral position. With the TC-SST vehicle, check that the

selector lever is in the "N" position. Then, start the engine of

the vehicle.

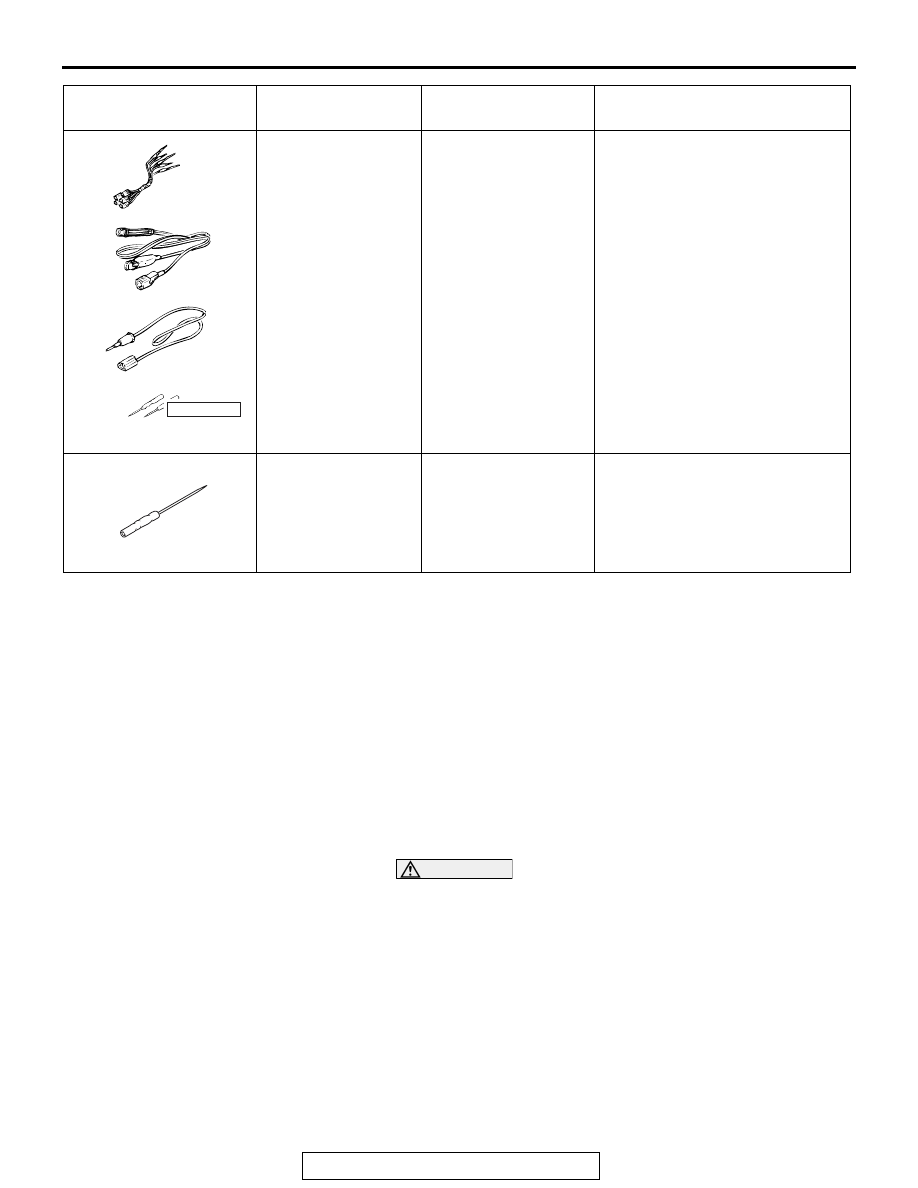

MB991223

a. MB991219

b. MB991220

c. MB991221

d. MB991222

Harness set

a. Test harness

b. LED harness

c. LED harness

adaptor

d. Probe

General service tools Continuity check and voltage

measurement at harness wire or

connector for loose, corroded or

damaged terminals, or terminals

pushed back in the connector.

a. Connector pin contact

pressure inspection

b. Power circuit inspection

c. Power circuit inspection

d. Commercial tester connection

MB992006

Extra fine probe

−

Continuity check and voltage

measurement at harness wire or

connector for loose, corroded or

damaged terminals, or terminals

pushed back in the connector.

Tool

Tool number and

name

Supersession

Application

MB991223

a

d

c

b

DO NOT USE

BA

MB992006