Mitsubishi Eclipse. Technical Information Manual (1994) - part 17

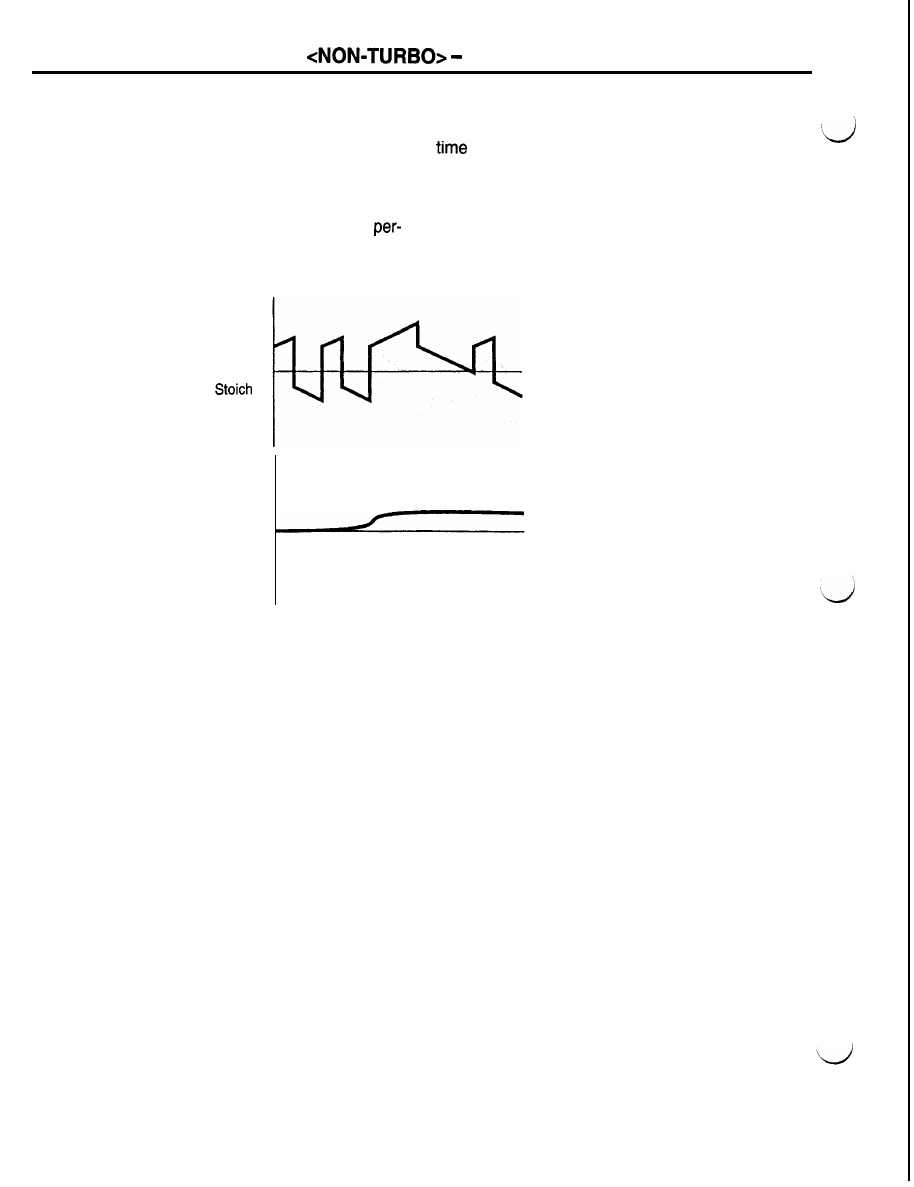

Long term memory also has control over pulse width

by being able to increase or decrease the pulse

width stored in the cell by up to 25%. Long term

memory is retained by the battery in the PCM, while

short term correction is lost whenever the ignition

is turned off.

The long term memory works to bring the short

term correction to the point where the average

1-46

ENGINE

Control System

cent of pulse width compensation it provides in this

memory cell is 0%. The long term memory returns

to this level of pulse width compensation the next

the vehicle enters this cell. It is in this way

that the PCM is continually relearning the most ap-

propriate level of control, even as the vehicle ages,

internal engine components wear, and operating

conditions change.

Short term fuel

compensation

A/F ratio

Long term fuel

compensation

There are several “purge free” cells. These cells

contain information on how much effect the canister

has on the air/fuel ratio. The purge solenoid is turned

on to shut off the purge flow and the cell is allowed

to register any purge corruption. The monitor looks

at the combination of short and long term fuel control

values to see if the system is in control.

The fuel system is continuously monitored during

each trip once the enabling conditions have been

AFUO094

met. Short term and long term values are multiplied

together. The test fails if the fuel control system

reduces pulse width by 25% long term memory and

7% short term compensation due to a rich condition

or increases pulse width by 25% long term memory

and 12% short term compensation due to a lean

condition.