Mitsubishi 380. Manual - part 889

COMBINATION METER ASSEMBLY

CHASSIS ELECTRICAL

54A-90

COMBINATION METER TERMINAL CHECK

M1543026700010

Measure the voltage between terminals using a volt-

meter.

NOTE: The combination meter connector is fixed on the instrument panel directly, so you can not take mea-

surement by backprobing.

CAUTION

Never take a measurement at terminals 14 and

15. If you do this, the CAN bus lines will be

impaired.

AC211750

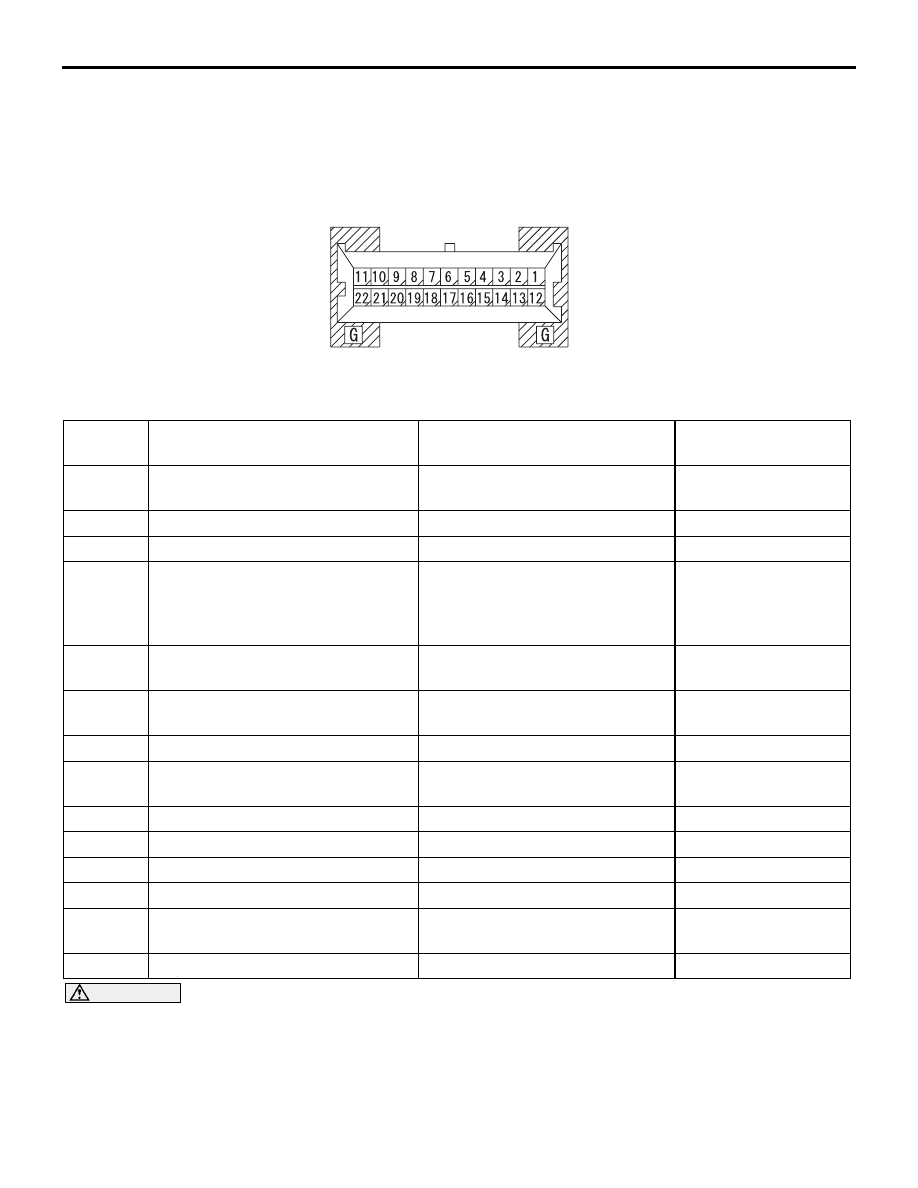

COMBINATION METER CONNECTOR

COMPONENT SIDE

AD

C-101

Terminal

No.

Check item

Check condition

Normal condition

1

Battery power supply

Always

Battery positive

voltage

3

Gauge ground

Always

0 V

5

Ground

Always

0 V

7

Parking brake switch and brake

fluid level switch

• Ignition switch: ON or parking

brake switch: ON

• Ignition switch: ON or brake

fluid level switch: ON

-

8

Seat belt switch

Ignition switch: ON or driver’s

seat belt not fastened

-

9

Engine oil pressure switch

Ignition switch: ON or engine oil

pressure switch: ON

-

11

Alternator (charge circuit)

-

-

12

Ignition switch (IG1) power supply

Ignition switch: ON

Battery positive

voltage

13

Fuel gauge

Always

-

16

Mode switch

Always

0 V

17

Mode switch (UP)

Always

0 V

18

Mode switch (DOWN)

Always

0 V

21

Illumination (power supply)

Lighting switch: ON

Battery positive

voltage

22

Illumination (ground)

Always

0 V