Mitsubishi 380. Manual - part 247

CHARGING SYSTEM

ENGINE ELECTRICAL

16-10

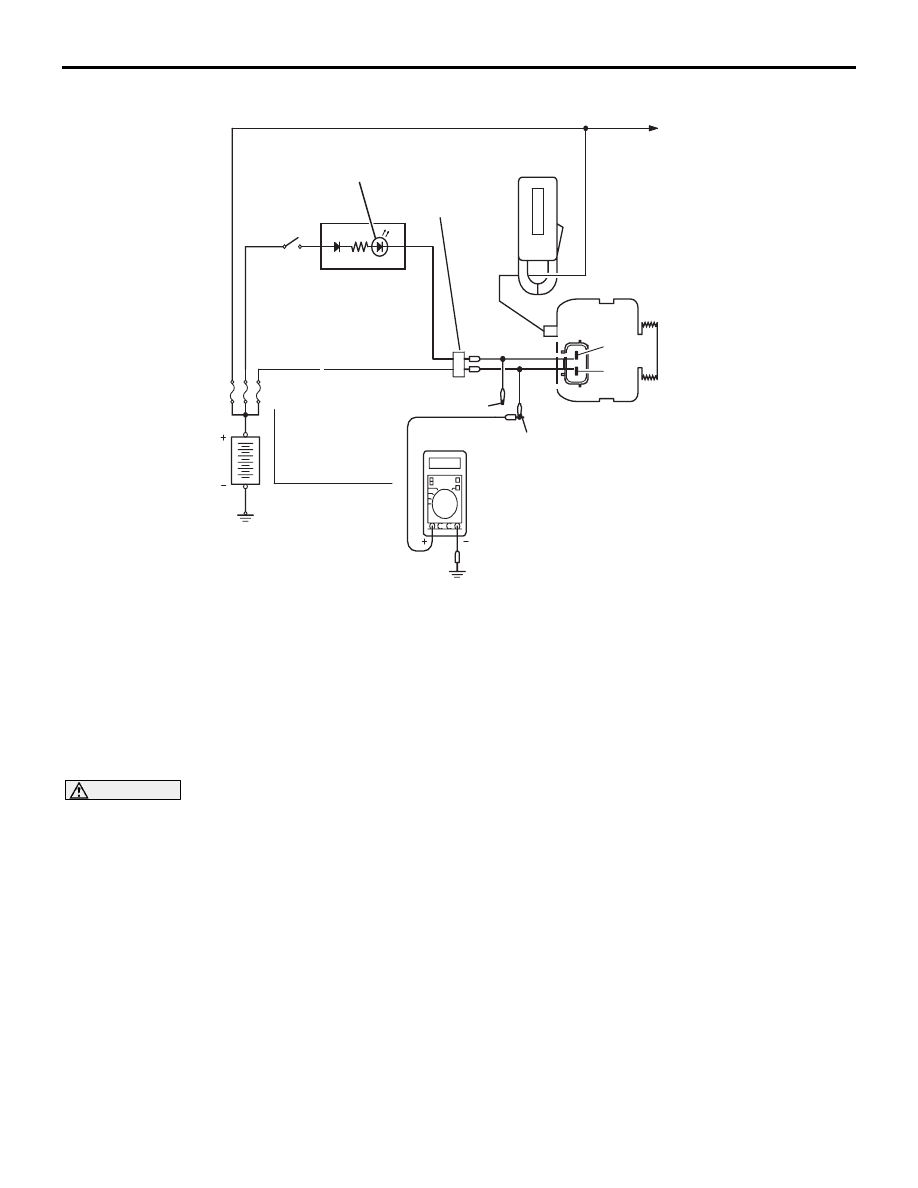

REGULATED VOLTAGE TEST

M1161001100666

Required Special Tools:

• : Diagnostic Tool (MUT-III)

• MB991824: V.C.I.

• MB991827: MUT-III USB Cable

• MB991910: MUT-III Main Harness A

• MB998467: Alternator Harness Connector

This test determines whether the voltage regulator is

correctly controlling the alternator output voltage.

WARNING

Battery posts, terminals and related acces-

sories contain lead and lead compounds.

WASH HANDS AFTER HANDLING.

1. Always be sure to check the following before the

test:

• Alternator installation

• Check to be sure that the battery installed in the

vehicle is fully charged. (Refer to GROUP 54A,

Chassis Electrical

− Battery − On-vehicle Service

− Battery Check

• Alternator drive belt tension (Refer to GROUP 00,

General

− Maintenance Service − Drive Belts

(For Alternator, Power Steering Pump and Air

Conditioning) (Check)

• Fusible link

• Abnormal noise from the alternator while the

engine is running.

2. Turn the ignition switch to the "LOCK" (OFF)

position.

3. Disconnect the negative battery cable.

4. Use the special tool (Alternator harness

connector: MB998467) to connect a digital-type

voltmeter between the alternator "S" terminal and

ground. (Connect the positive lead of the

voltmeter to the "S" terminal, and then connect the

negative lead of the voltmeter to a secure ground

or to the negative battery terminal.)

5. Connect a clamp-type DC test ammeter with a

range of 0

− 120 A to the alternator "B" terminal

output wire.

6. Reconnect the negative battery cable.

7. Connect an engine tachometer, or diagnostic tool.

8. Turn the ignition switch to the "ON" position and

check that the reading on the voltmeter is equal to

the battery positive voltage.

NOTE: If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator "S" terminal and the battery positive

terminal or malfunctioning voltmeter.

9. Check to be sure that all lights and accessories

are off.

10.Start the engine.

06DB025A

BATTERY

IGNITION

SWITCH

AMMETER

(CLAMP-TYPE)

LOAD

MB998467

VOLTMETER (DIGITAL-TYPE)

RED

YELLOW

ALTERNATOR

B

ALTERNATOR

MALFUNCTION

LIGHT

COMBINATION

METER

L

S