Mitsubishi 380. Manual - part 213

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONING AND VENTILATION

55-148

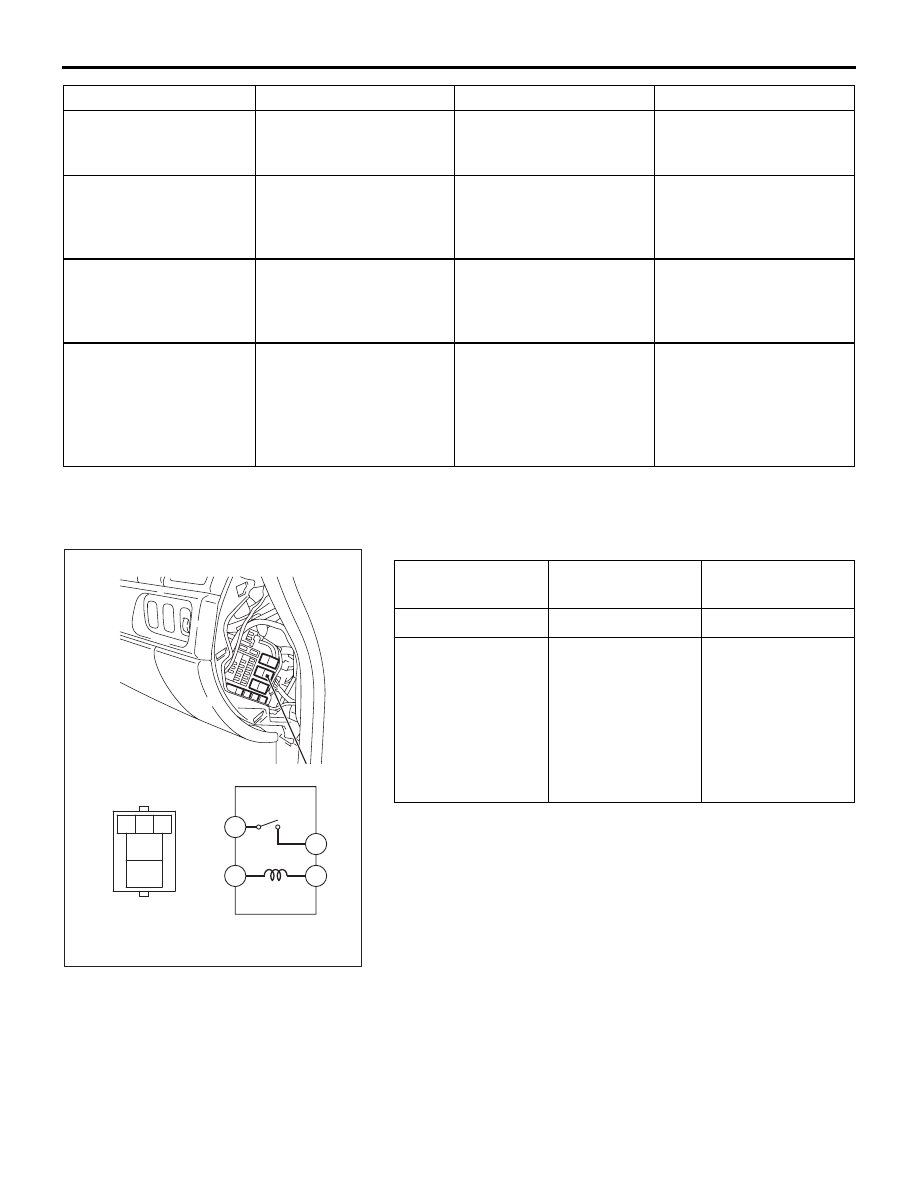

POWER RELAY CHECK

M1552008800321

BLOWER RELAY CONTINUITY CHECK

Hissing or swishing

noise

Low refrigerant quantity

Refrigerant level

Check system for leaks

and charge to

specification

Rattling (Internal

compressor)

Lack of lubricating oil. In a

system with a gas leak

the oil has escaped with

the refrigerant

Rattling noise from

internal compressor

Repalce the compressor

and also fix the system

leak to prevent

reoccurrance

Wooing (Resonant

noise)

Drive accessory (P/S

pump, Alternator,etc)

resonating at specific

engine speed

The drive accessories for

vibration

Stop vibrations of the

assembly or modify

transmission route to the

vehicle body

Cooing (Discharge

pulsation noise)

Pressure fluctuation of

refrigerant discharged

from compressor, which

vibrates the high pressure

piping

Remove the piping

mounting clamps and

re-check. Hold the

condenser without

mountings by hand and

re-check

Put rubber bush between

pipe clamps and the

vehicle body. decrease

refrigerant to minimum

specified level.

NOISE DESCRIPTION

POSSIBLE CAUSE

CHECK

REPAIR

BATTERY

VOLTAGE

TESTER

CONNECTION

SPECIFIED

CONDITION

Not applied

4

− 5

Open circuit

• Connect

terminal 1 to the

positive battery

terminal

• Connect

terminal 3 to the

negative battery

terminal

4

− 5

Less than 2 ohms

25DB057A

4

5

1 2 3

5

1

4

3

BLOWER RELAY