Range Rover 2. Electrical Manual - part 23

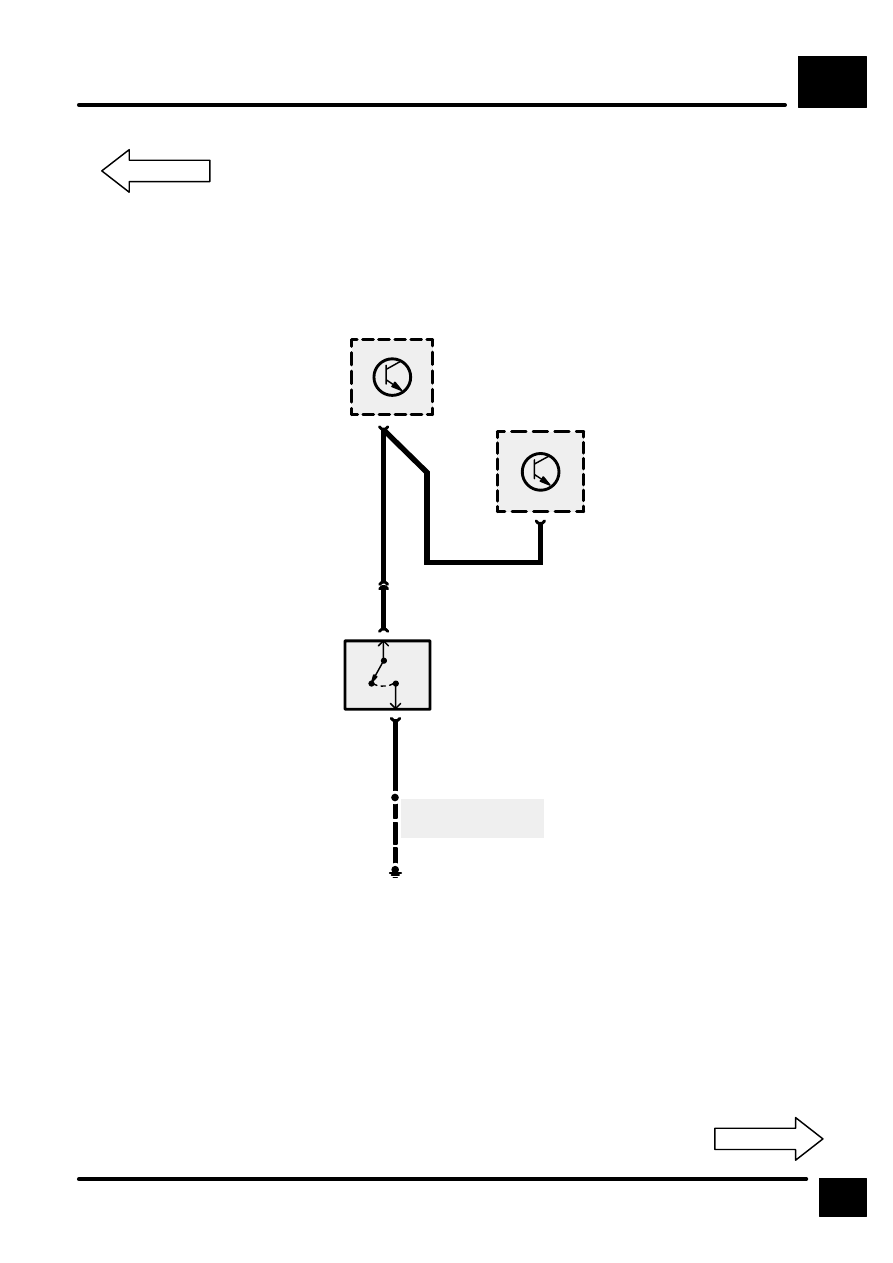

TRANSFER GEARBOX

B6

7

CIRCUIT DIAGRAM

18

C626

1

N

2

0

1

34

C603

E529

S551

N

B

See Ground Dis-

tribution

C660

11

C560

C563

C563

E574

Petrol

Diesel

Z238

Body Electrical

Control Module

(BECM)

X293

Neutral Switch

Z256

Transfer Gear

Box ECU

Manual Trans-

mission