Discovery 2. Manual - part 481

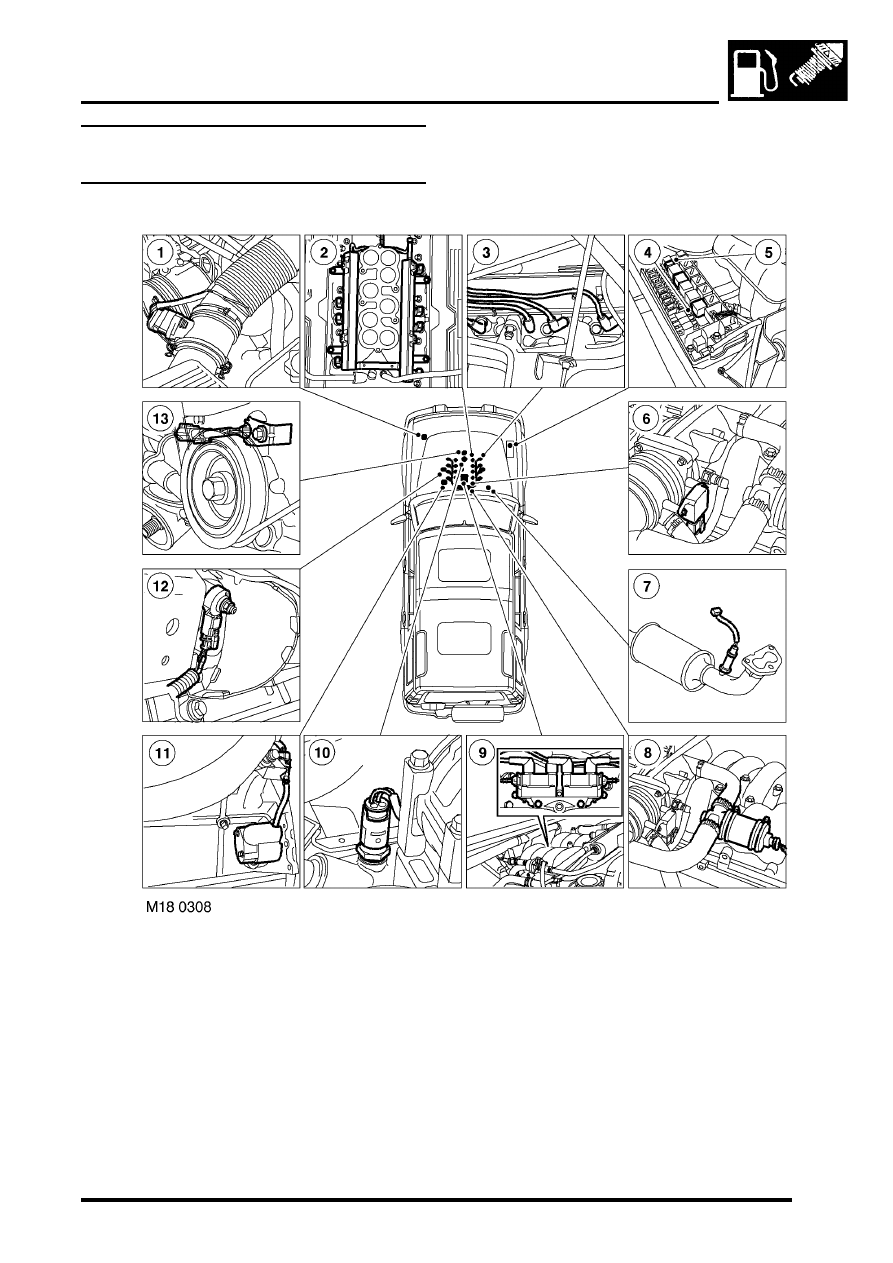

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION

18-2-3

Engine management component

location - Engine compartment

1 Mass air flow/ inlet air temperature sensor

2 Fuel injectors

3 High tension leads/spark plugs

4 Fuel pump relay

5 ATC compressor clutch relay/ cooling fan relay

6 Throttle position sensor

7 Heated oxygen sensor

8 Idle air control valve

9 Ignition coils

10 Engine coolant temperature sensor

11 Crankshaft speed and position sensor

12 Knock sensor

13 Camshaft position sensor