Isuzu N-Series. Manual - part 826

7C-6 CLUTCH

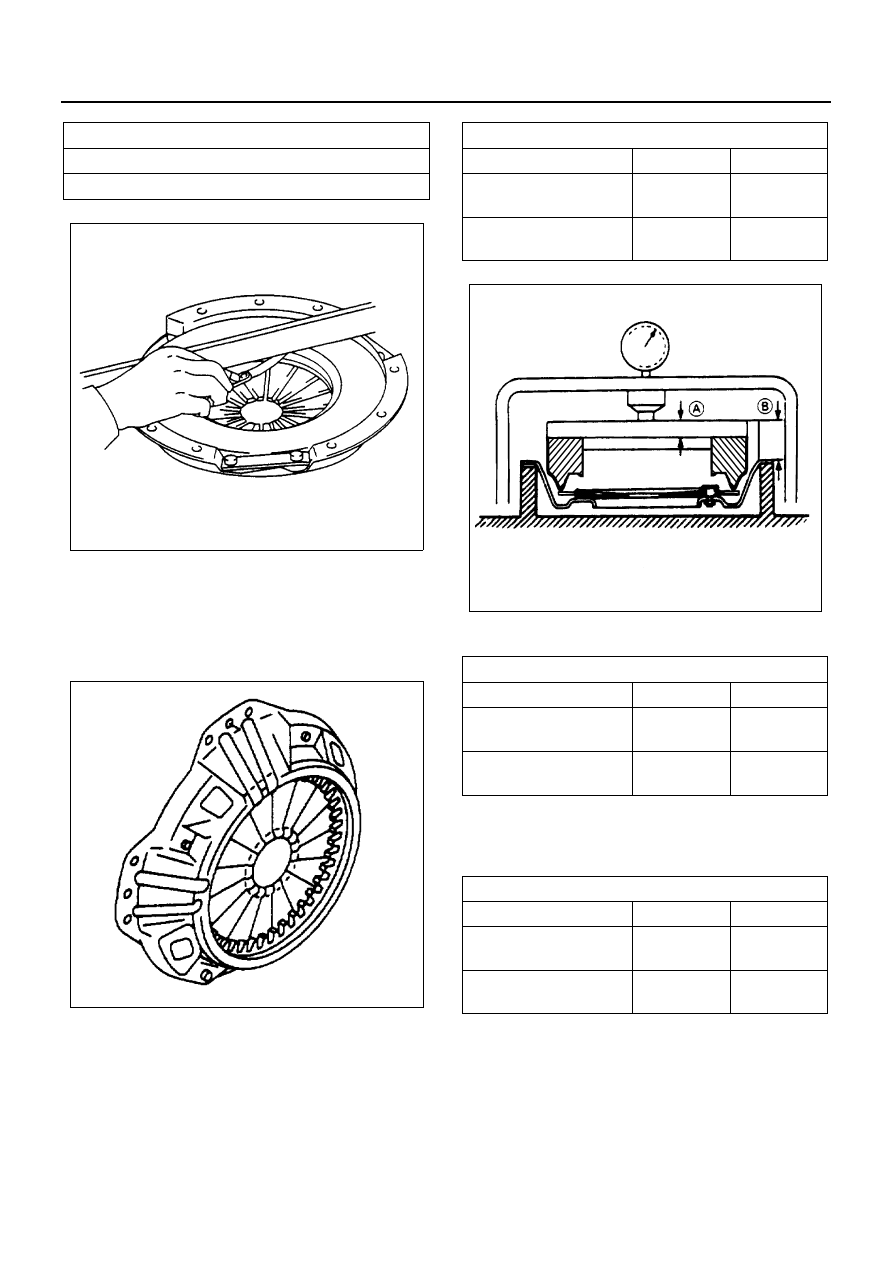

Clutch Cover

• Visually inspect the entire clutch cover for ex-

cessive wear, cracking, and other damage.

The pressure plate assembly must be replaced

if any of these conditions are present.

Clutch Set Force

1) Invert the pressure plate assembly.

2) Place a metal sheet with thickness “A” on the

pressure plate.

3) Compress the pressure plate assembly until

the distance “B” becomes specified.

4) Note the pressure plate gauge reading.

Diaphragm Spring Finger Height

1) Place distance pieces beneath the pressure

plate and clutch cover.

2) Fully compress the pressure plate assembly.

There are two ways to do this.

a. Use a bench press to press down on the pres-

sure plate assembly from the top.

b. Tighten the pressure plate assembly fixing

bolts.

3) Measure the spring finger height from base to

spring tip.

Pressure Plate Warpage

mm (in)

Limit

0.3 (0.01)

N7A0214E

N7A0215E

Thickness and Distance

mm (in)

A

B

NKR55

Clutch Size

φ 240

7.4 (0.29)

18 (0.71)

NHR55/NKR55/NHR69

Clutch Size

φ 250

8.0 (0.31)

18 (0.71)

Clutch Set Force

N (kg/lb)

Standard

Limit

NKR55

Clutch Size

φ 240

4,116

(420/926)

3,785

(386/851)

NHR55/NKR55/NHR69

Clutch Size

φ 250

6,276

(640/1,411)

5,776

(589/1,299)

Distance Piece

mm (in)

A

B

NKR55

Clutch Size

φ 240

7.4 (0.29)

18 (0.71)

NHR55/NKR55/NHR69

Clutch Size

φ 250

8.0 (0.31)

18 (0.71)

N7A0571E