Isuzu N-Series. Manual - part 819

7B-46 MANUAL TRANSMISSION (MSB)

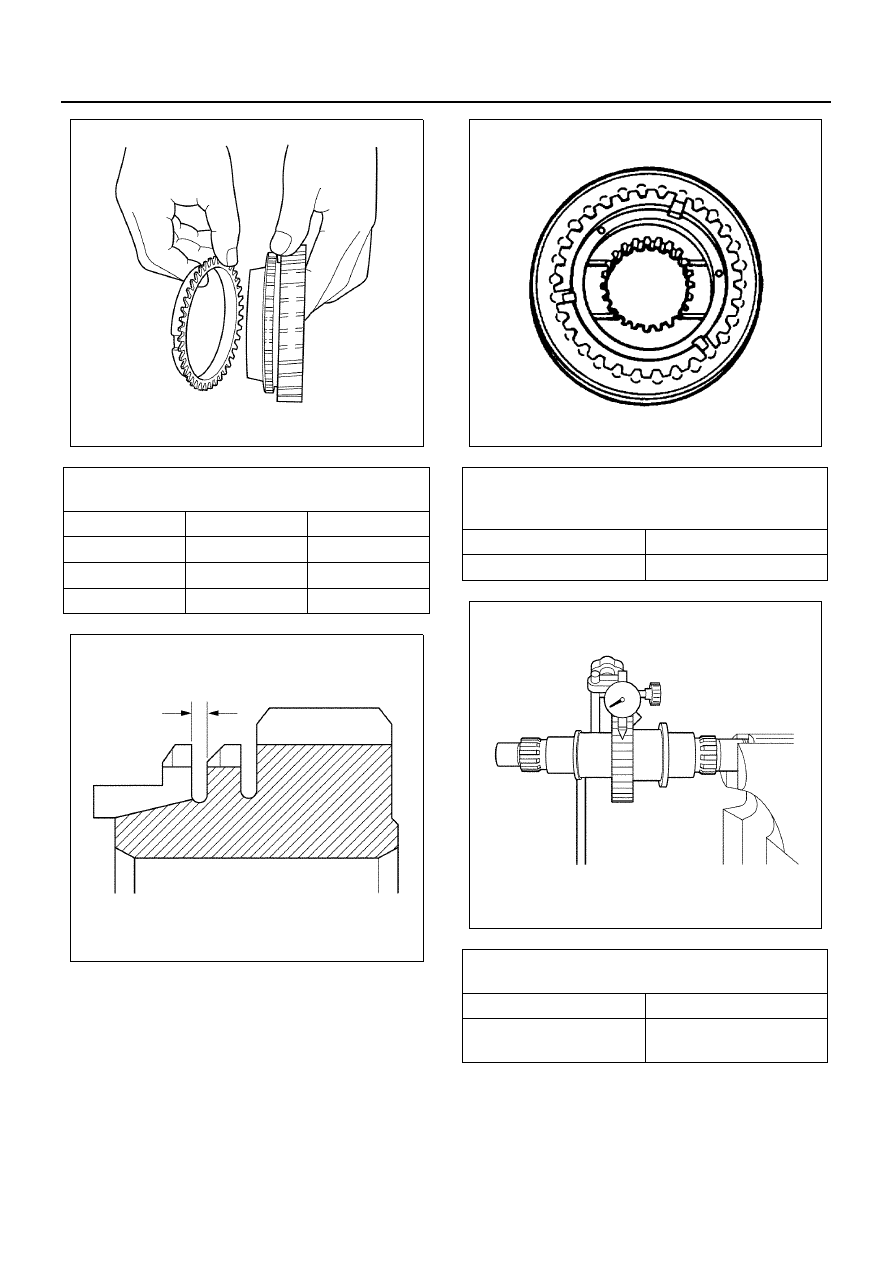

• Wears or damages found on the clutch hub, the

sliding sections of the sleeve, the spline sec-

tions and insert grooves.

Block Ring and Dog Gear Teeth

Clearance

mm (in)

Gear

Standard

Limit

3rd/4th

1.0 (0.04)

0.5 (0.02)

1st/2nd

1.5 (0.06)

0.5 (0.02)

5th

1.5 (0.06)

0.5 (0.02)

N7A1203E

N7A1204E

Clutch Hub Spline Play

(At clutch hub outer cir-

cumference)

mm (in)

Standard

Limit

0 — 0.05 (0 — 0.002)

0.3 (0.01)

Block Ring Groove and

Insert Clearance

mm (in)

Standard

Limit

3.59 — 3.91 (0.141 —

0.154)

4.1 (0.16)

N7A0147E

N7A1206E