Isuzu N-Series. Manual - part 769

Engine Control System (4JH1) 6E-127

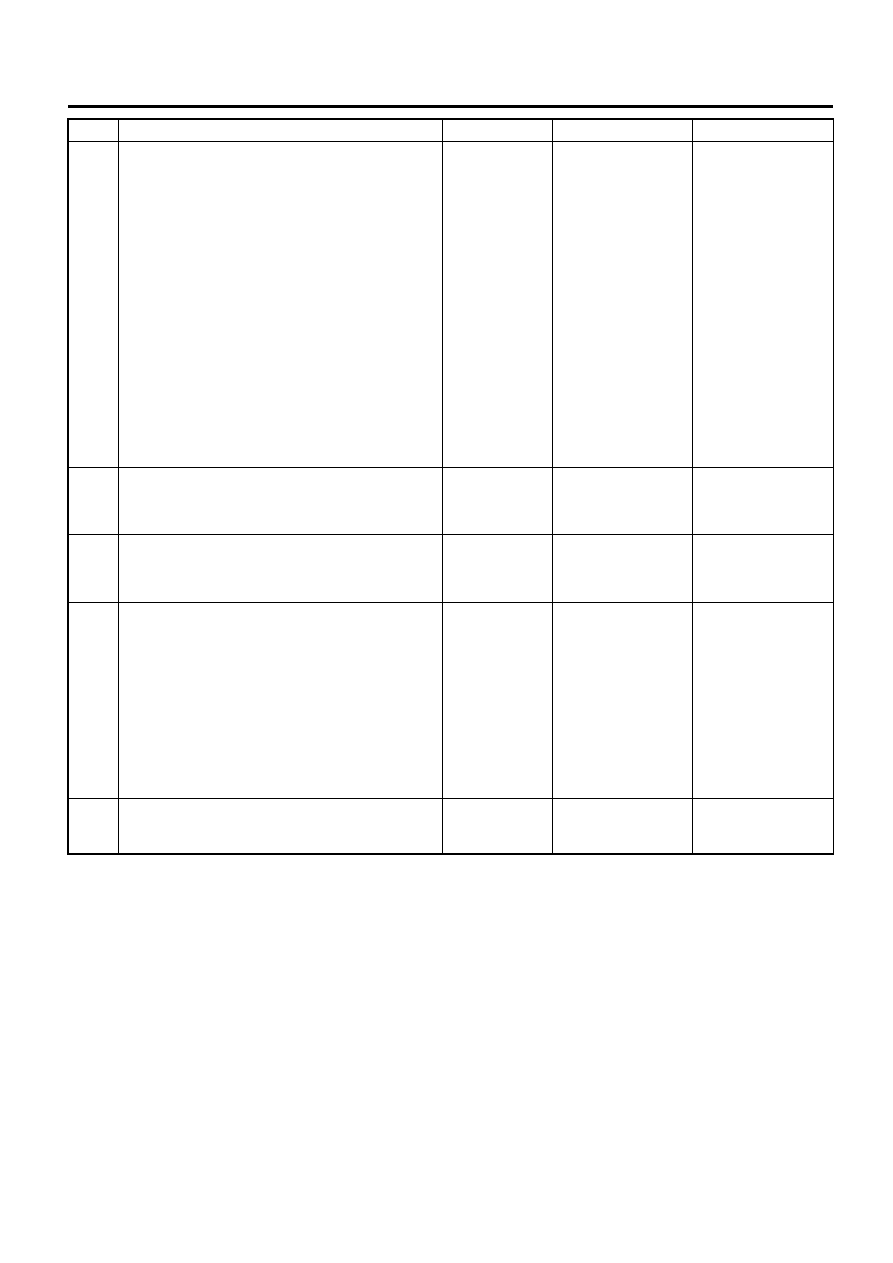

7

1.

Turn OFF the ignition.

2.

Disconnect the MAF sensor harness

connector.

3.

Inspect for an intermittent, for a poor

connection and corrosion at the harness

connector of the MAF sensor (pin 3 of J-182

connector).

4.

Disconnect the engine control module (ECM)

harness connector.

5.

Inspect for an intermittent, for a poor

connection and corrosion on each MAF

sensor circuit at the harness connector of the

ECM (pin 92 of B-233 connector).

6.

Test for high resistance on each MAF sensor

circuit.

7.

Repair the circuit(s) as necessary.

Did you find and correct the condition?

—

Go to Step 10

Go to Step 8

8

Replace the EGR valve. Refer to EGR Valve

Replacement in engine mechanical section.

Did you complete the replacement?

—

Go to Step 10

—

9

Replace the EGR solenoid valve. Refer to EGR

Solenoid Valve Replacement in this section.

Did you complete the replacement?

—

Go to Step 10

—

10

1.

Reconnect all previously disconnected

harness connector(s).

2.

Clear the DTCs with the Tech 2.

3.

Turn OFF the ignition for 30 seconds.

4.

Start the engine and warm up (allow engine

coolant temperature to reach at least 75

°C

[167

°F]) while observing the MAF Sensor

parameter with the Tech 2.

Does the MAF Sensor parameter follow the

Desired MAF parameter within 50 mg/strk?

—

Go to Step 11

Go to Step 2

11

Observe the DTC Information with the Tech 2.

Are there any DTCs that you have not diagnosed?

—

Go to Diagnostic

Trouble Code (DTC)

List

System OK

Step

Action

Value(s)

Yes

No