Isuzu N-Series. Manual - part 768

Engine Control System (4JH1) 6E-123

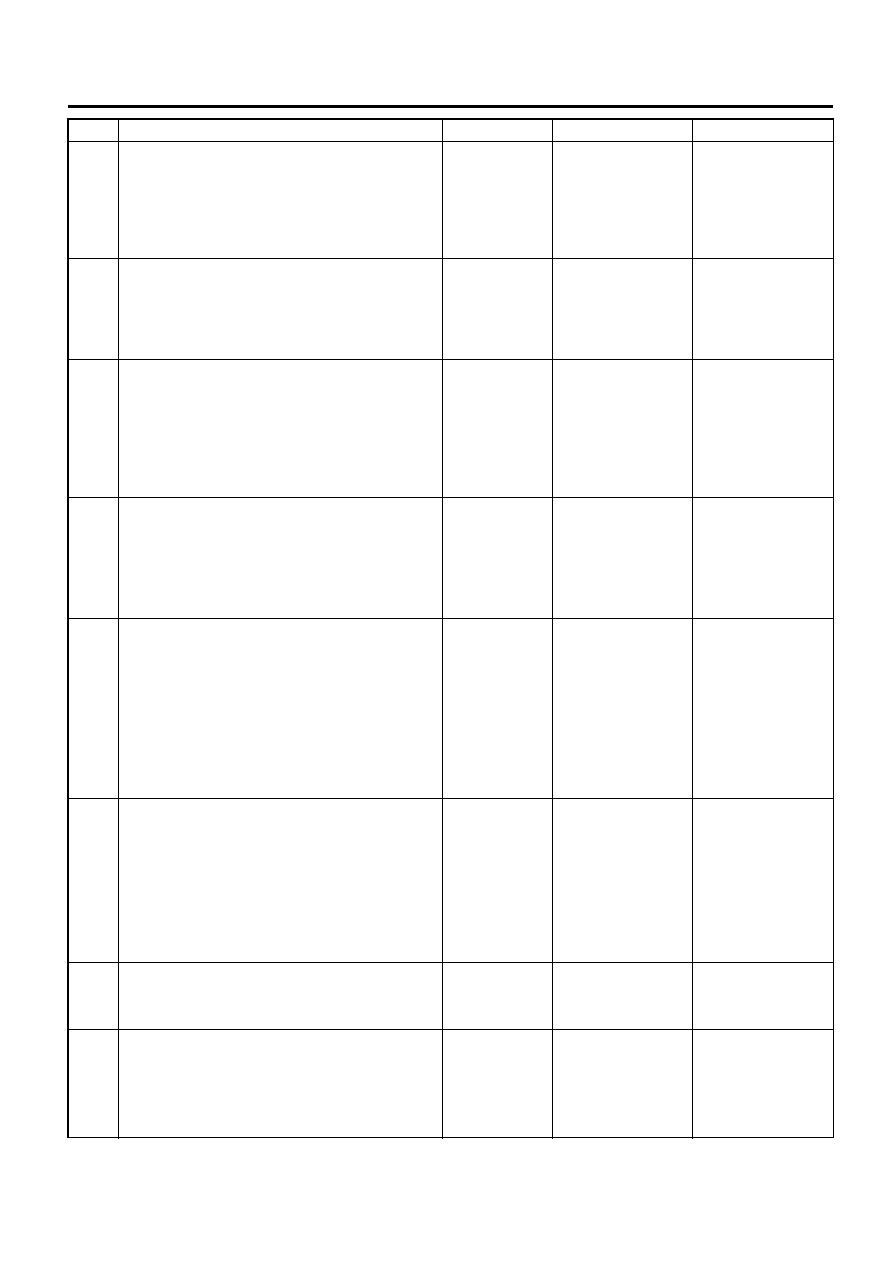

5

Command the EGR Solenoid Valve OFF with the

Tech 2.

Does the test lamp continuously illuminate same as

Step 4 when commanded OFF with the Tech 2 (the

test lamp slightly illuminates if the circuit is normal

when commanded OFF)?

—

Go to Step 8

Go to Step 9

6

Repair the open circuit or high resistance on the

voltage feed circuit between the ECM main relay

(pin 5 of X-14 connector) and the EGR solenoid

valve (pin 1 of J-105 connector).

Did you complete the repair?

—

Go to Step 13

—

7

1.

Test the control circuit between the engine

control module (ECM) (pin 97 of B-233

connector) and the EGR solenoid valve (pin 2

of J-105 connector) for an open circuit or high

resistance.

2.

Repair the circuit(s) as necessary.

Did you find and correct the condition?

—

Go to Step 13

Go to Step 10

8

1.

Test the control circuit between the ECM (pin

97 of B-233 connector) and the EGR solenoid

valve (pin 2 of J-105 connector) for a short to

ground.

2.

Repair the circuit(s) as necessary.

Did you find and correct the condition?

—

Go to Step 13

Go to Step 12

9

1.

Turn OFF the ignition.

2.

Disconnect the EGR solenoid valve harness

connector.

3.

Inspect for an intermittent and for poor

connections at the harness connector of the

EGR solenoid valve (pins 1 and 2 of J-105

connector).

4.

Repair the connection(s) as necessary.

Did you find and correct the condition?

—

Go to Step 13

Go to Step 11

10

1.

Turn OFF the ignition.

2.

Disconnect the ECM harness connector.

3.

Inspect for an intermittent and for a poor

connection on the EGR solenoid valve control

circuit at the harness connector of the ECM

(pin 97 of B-233 connector).

4.

Repair the connection(s) as necessary.

Did you find and correct the condition?

—

Go to Step 13

Go to Step 12

11

Replace the EGR solenoid valve. Refer to EGR

Solenoid Valve Replacement in this section.

Did you complete the replacement?

—

Go to Step 13

—

12

Important:

Replacement ECM must be programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

—

Go to Step 13

—

Step

Action

Value(s)

Yes

No