Isuzu N-Series. Manual - part 666

6E-86 Engine Control System (4HK1)

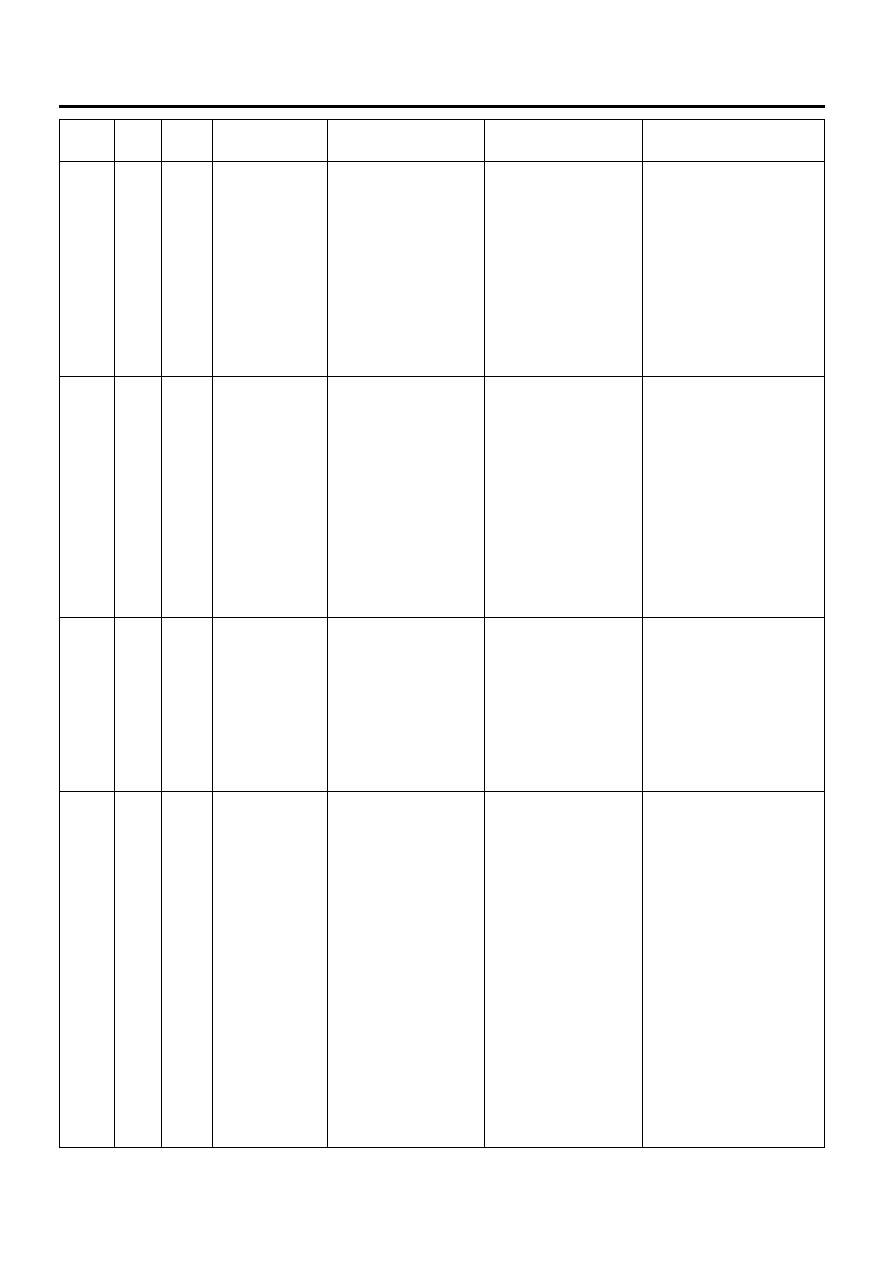

P1635

55

ON

5V Reference

Circuit 5

• DTC P1630 is not

set.

• The ignition switch is

ON.

• The battery voltage

is between 16 – 32

volts.

Either of following

condition is met:

• The ECM detects

that the 5 volts

reference circuit 2 or

5 voltage is less

than 4.5 volts.

• The ECM detects

that the 5 volts

reference circuit 2 or

5 voltage is more

than 5.5 volts.

• Same as DTC P1632.

P1681

46

ON

Exhaust Brake

Valve Circuit Low

Voltage

• The ignition switch is

ON.

• The battery voltage

is between 16 – 32

volts.

• The engine is

running.

• The ECM detects a

low voltage

condition on the

exhaust brake

solenoid valve

control circuit for

longer than 10

seconds when the

solenoid valve is

commanded OFF.

• Exhaust brake solenoid

valve voltage feed circuit

is open circuit or high

resistance.

• Exhaust brake solenoid

valve control circuit is

short to ground, open

circuit or high resistance.

• Poor harness connector

connection.

• Faulty exhaust brake

solenoid valve.

• Faulty ECM.

P1682

46

ON

Exhaust Brake

Valve Circuit

High Voltage

• The ignition switch is

ON.

• The battery voltage

is between 16 – 32

volts.

• The engine is

running.

• The ECM detects a

high voltage

condition on the

exhaust brake

solenoid valve

control circuit for

longer than 10

seconds when the

solenoid valve is

commanded ON.

• Exhaust brake solenoid

valve control circuit is

short to battery or

ignition voltage.

• Faulty exhaust brake

solenoid valve.

• Faulty ECM.

U2104

84

ON

CAN Bus Reset

Counter Overrun

• The ignition switch is

ON.

• The ECM detects

that the CAN Bus

OFF status.

• CAN Low circuit is short

to battery, ignition

voltage, short to ground,

open circuit or high

resistance.

• CAN High circuit is short

to battery, ignition

voltage, short to ground,

open circuit or high

resistance.

• Faulty resistor 1.

• Faulty resistor 2.

• Faulty ECM.

• Faulty DRM.

• Faulty TCM.

• Faulty EHCU.

• Electromagnetic

interference and

electrical noise.

DTC

Flash

Code

MIL

Status

DTC Name

Condition for Running

the DTC

Condition for Setting the

DTC

Possible Cause