Isuzu N-Series. Manual - part 659

6E-58 Engine Control System (4HK1)

Lost Communication with The Engine Control Module (ECM)

Circuit Description

The engine control module (ECM), transmission control

module (TCM) and supplemental restraint system

(SRS) control module communicates with the Tech 2

over the Keyword 2000 serial data link. The hill start aid

(HSA) control module communicates with the Keyword

82 serial data link. However, the ECM, TCM, electric

hydraulic control module (EHCU) (ABS module) and

the data recording module (DRM) communicate with

each other over the controller area network (CAN) link.

The CAN link is not used for communication with the

Tech 2 and is shared only among each module.

Lost Communication with The Engine Control

Module (ECM)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

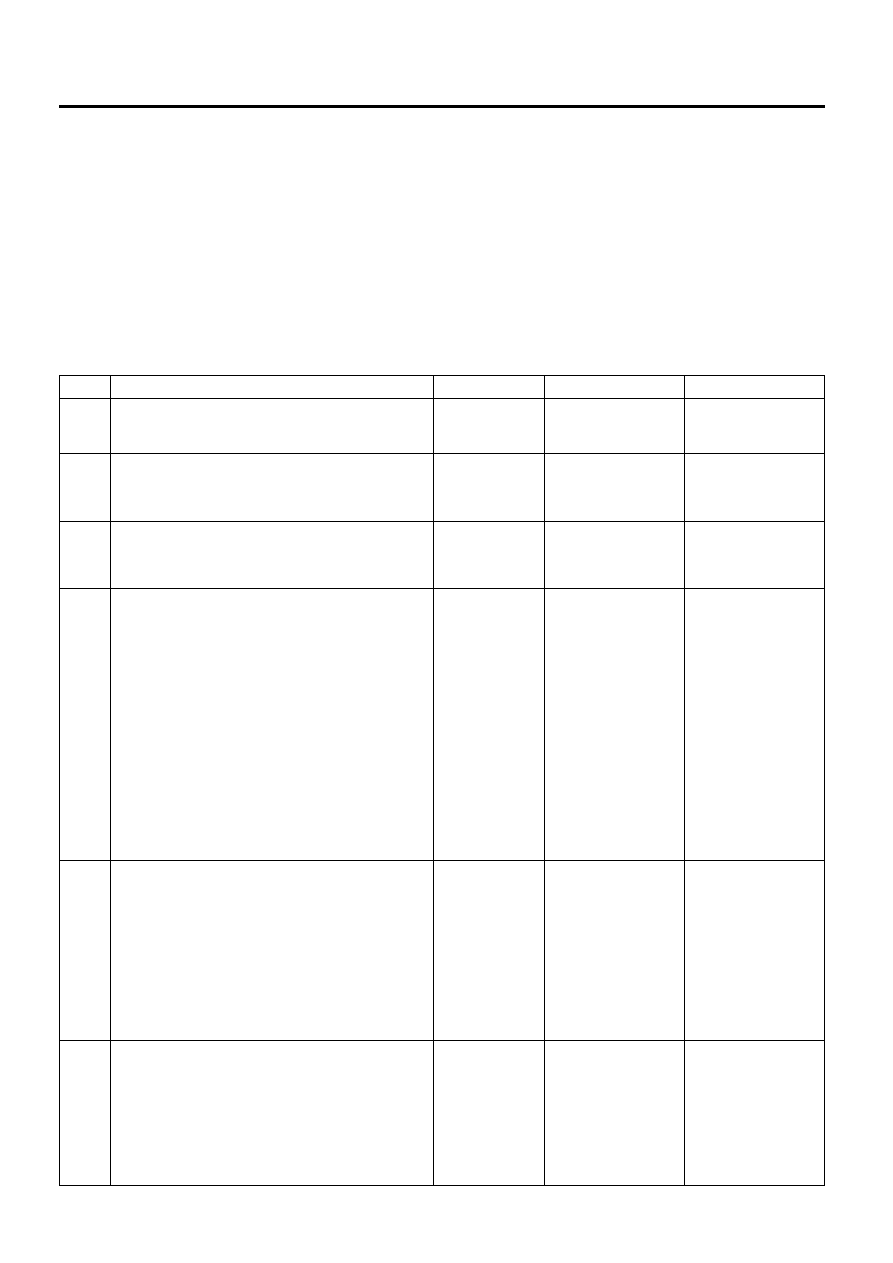

Step

Action

Value(s)

Yes

No

1

Did you perform the Diagnostic System Check –

Engine Controls?

—

Go to Step 2

Go to Diagnostic

System Check –

Engine Controls

2

Attempt to establish engine control module (ECM)

communications with the Tech 2.

Does the ECM communicate with the Tech 2?

—

Go to Intermittent

Conditions

Go to Step 3

3

Check the ECM E-111 and J-191 connectors for

poor connections.

Did you find and correct the condition?

—

Go to Step 15

Go to Step 4

4

1.

Turn ON the ignition, with the engine OFF.

2.

Check the ECM (40A) slow blow fuse, ECM

(10A) fuse and Engine (IG) (10A) fuse.

Replace and retest if open. If any fuse

continues to open, check for a short to ground

on each circuit fed by that fuse.

3.

Turn OFF the ignition.

4.

Disconnect the ECM J-191 harness

connector.

5.

Turn ON the ignition, with the engine OFF.

6.

Connect a test lamp to ground and check for

voltage at the ignition voltage supply circuit at

the ECM (pin 24 of J-191 connector).

Does the test lamp illuminate?

—

Go to Step 5

Go to Step 12

5

1.

Turn OFF the ignition.

2.

Connect a DMM between the Keyword serial

data circuit at the ECM (pin 38 of J-191

connector) and the data link connector (DLC)

(pin 7 of B-79 connector).

3.

Test the circuits for an open circuit or high

resistance.

4.

Repair the circuit(s) as necessary.

Did you find and correct the condition?

—

Go to Step 15

Go to Step 6

6

Important:

An open in a ground circuit at the ECM will not

cause a loss of communication.

1.

Check ECM ground for corrosion and

tightness.

2.

Clean or tighten grounds as necessary.

Did you find and correct the condition?

—

Go to Step 15

Go to Step 7