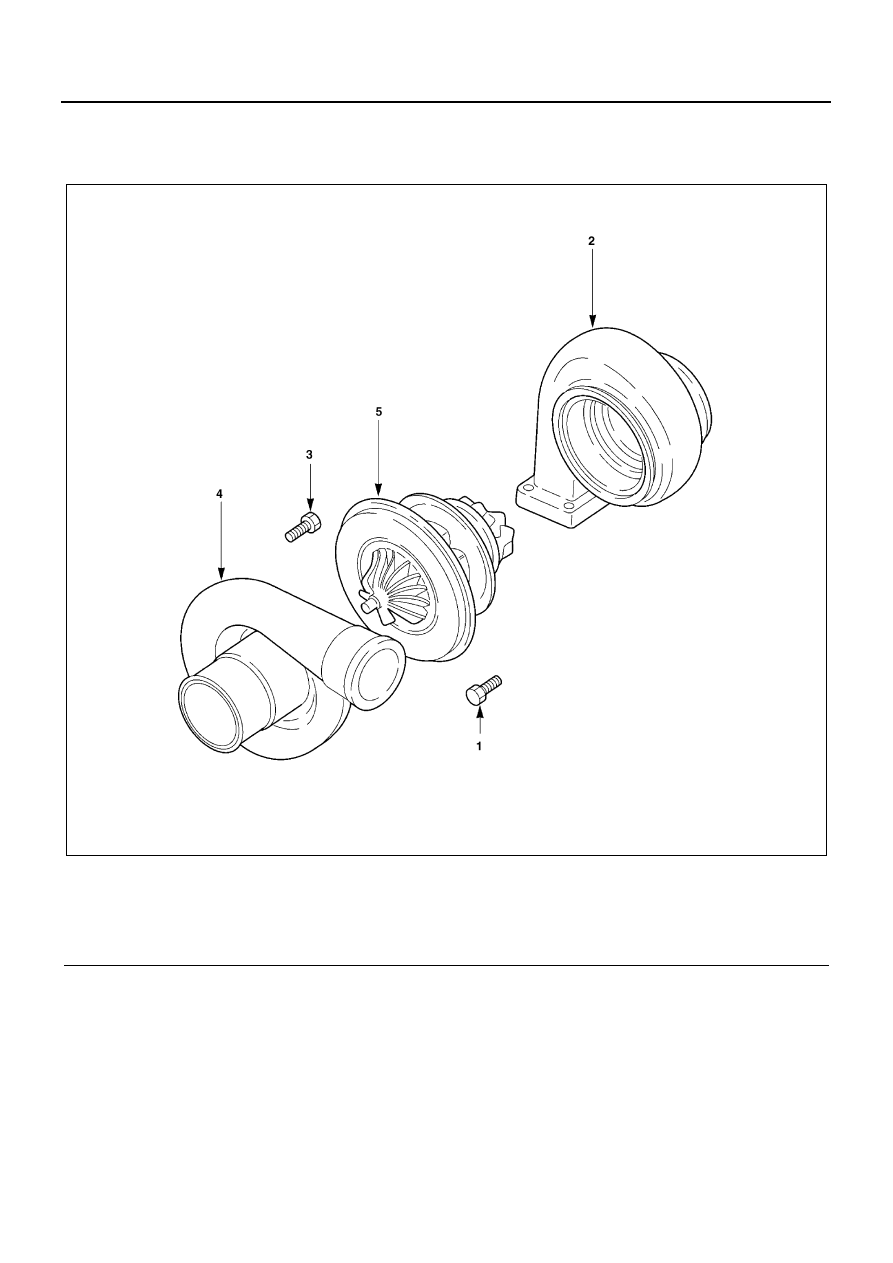

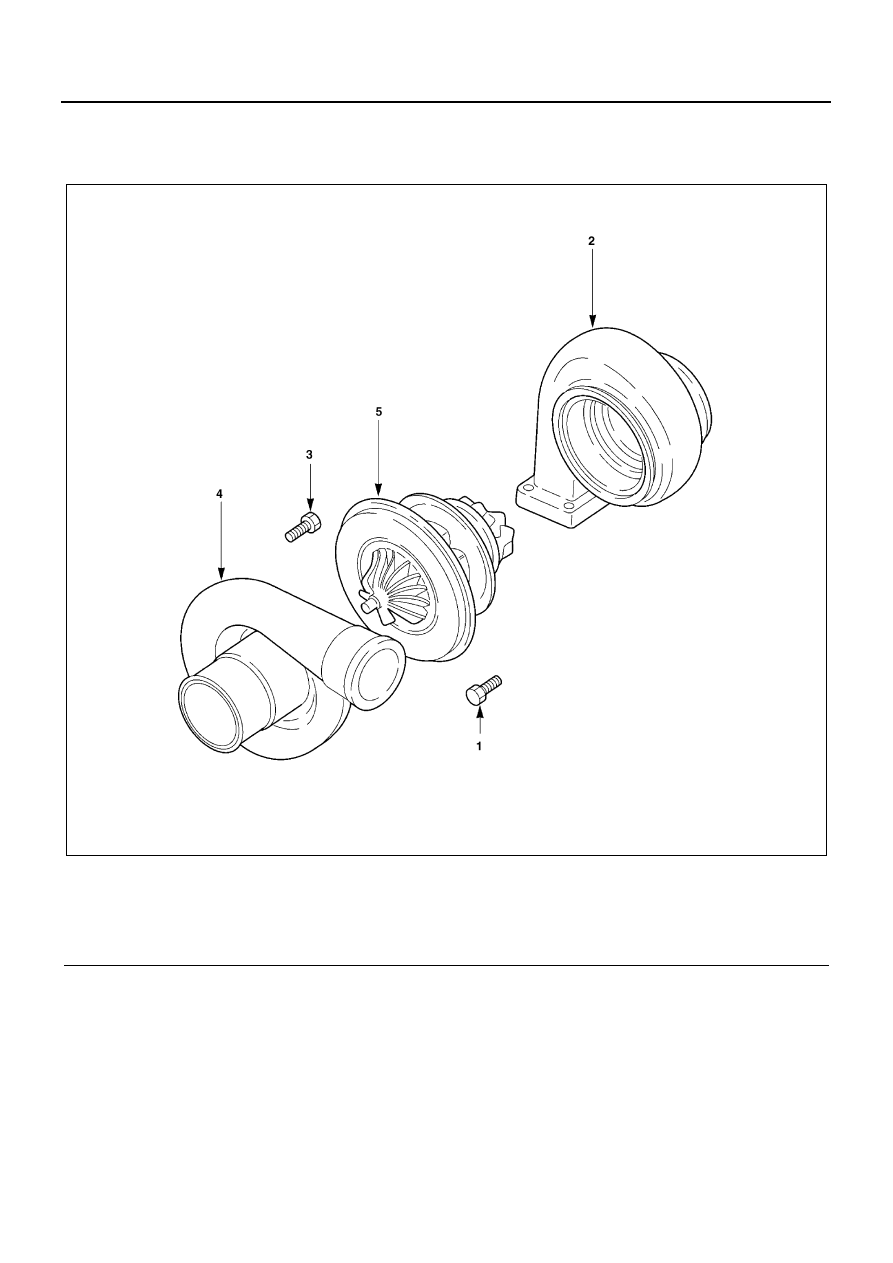

Isuzu N-Series. Manual - part 643

TURBOCHARGER 6G-5

DISASSEMBLY

Component

Legend

1. Bolt

4. Compressor housing

2. Turbine housing

5. Center housing and rotating assembly

3. Bolt

N6A3603E

|

|

|

TURBOCHARGER 6G-5 DISASSEMBLY Component Legend 1. Bolt 4. Compressor housing 2. Turbine housing 5. Center housing and rotating assembly 3. Bolt N6A3603E |