Isuzu N-Series. Manual - part 588

6A1-40 4JB1/4JB1-TC/4JG2/4JH1-TC - ENGINE

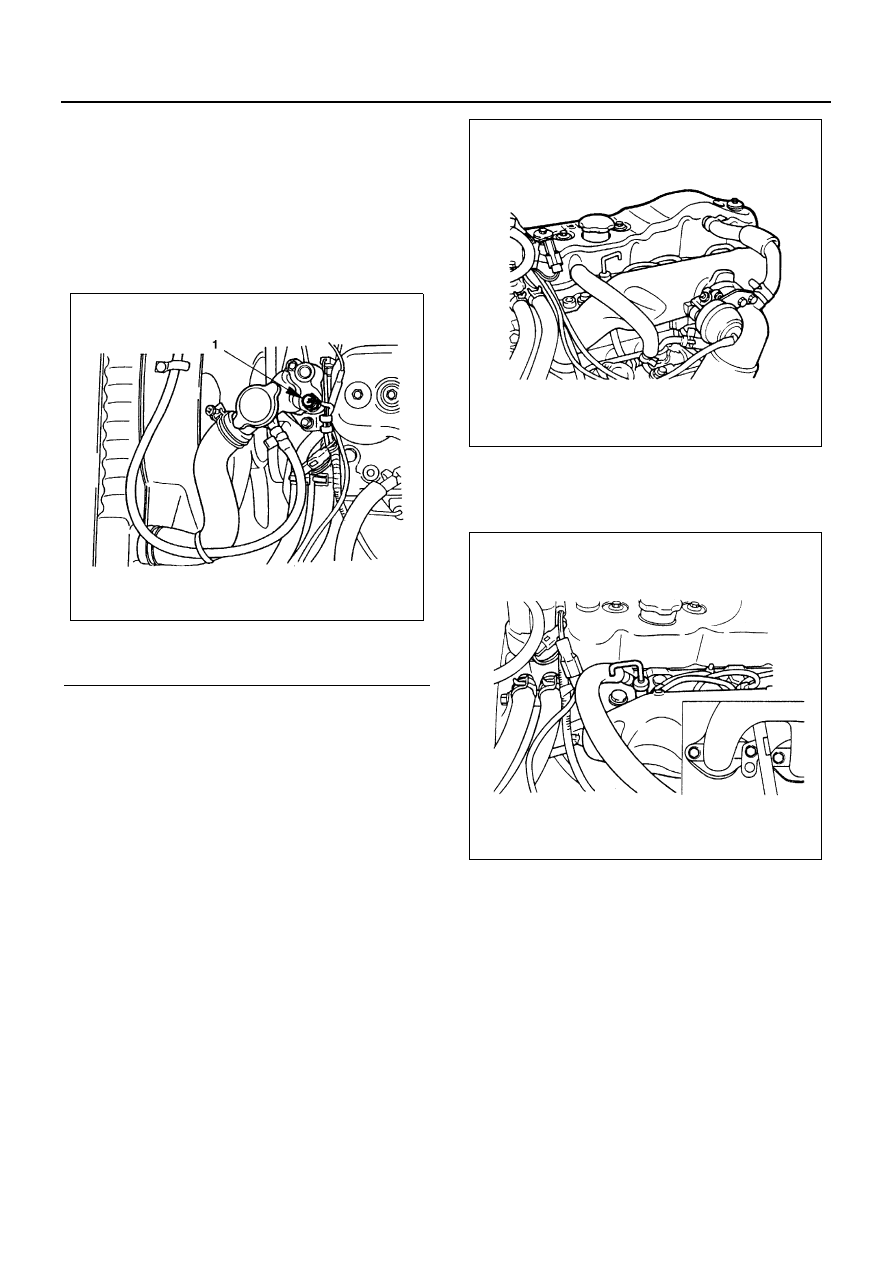

2. Heater Hose

• Disconnect heater hose from heater pipe.

3. A/C Compressor Drive Belt

• Loosen idler lock nut.

• Loosen adjust bolt and remove drive belt.

4. Engine Harness

• Disconnect harness connectors from units on ther-

mostat housing.

5. Air Intake Duct

• Remove the clip and air intake duct.

6. Injection Pipe

• Release injection pipe clip.

• Remove flare nut injection pump side.

• Remove flare nut injection nozzle side and remove

injection pipe.

Notice:

Plug the injection nozzle holder and the delivery holder

to prevent the entry of foreign matters into them.

7. Leak Off Pipe

• Remove the leak off pipe side of leak off hose.

8. PCV Hose

• Remove the PCV hose from air intake pipe.

9. Glow Plug Harness

10. Oil Level Gauge Guide Tube

• Remove the guide tube from cylinder head.

11. Oil Cooler Water Pipe (Oil Cooler Model)

• Remove the pipe fixing bolt of cylinder head rear

side.

• Remove the oil cooler water pipe fixing nut from in-

let manifold.

Legend

1. Thermo-sensor

N6A3286E

N6A3287E

N6A3288E