Isuzu N-Series. Manual - part 502

Engine Mechanical (4HK1-TC) 6A-113

• Disconnect the front frame harness connector

near the control box of the transmission,

remove the clips that fix the harness.

• Remove the two bolts on the upper side and

lower side that fix the starter, remove the starter

from the clutch housing.

• Use wire to secure the starter to the

transmission. Position the wire and starter so

that it does not interfere with the transmission

removal procedure.

2. Remove the transmission assembly.

Refer to “Engine Assembly”.

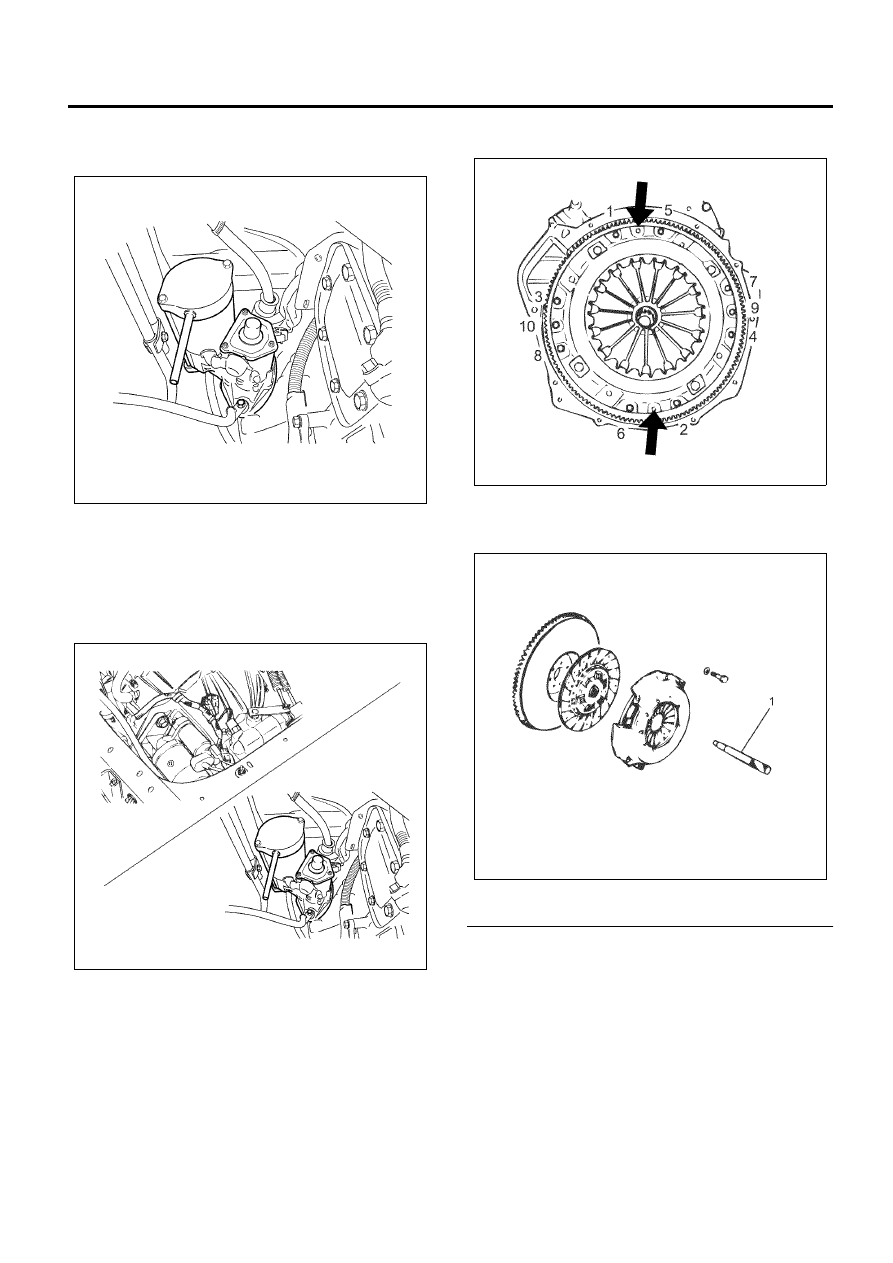

3. Remove the clutch pressure plate assembly.

• Insert the clutch aligner on the spline of the

driven plate.

• Remove the clutch pressure plate assembly

installation bolts in the order shown in the

drawing.

• Remove the clutch pressure plate assembly

from the flywheel.

4. Remove the clutch plate assembly.

• Remove the clutch plate assembly from the

flywheel along with the clutch aligner (1).

Legend

1. Clutch Aligner

• Install the crankshaft stopper in the starter

installation part of the flywheel housing.

Caution:

Make sure that the stopper is applied with the ring gear

and installed properly.

N6A6215E

N6A6216E

N6A6217E

N6A6218E