Isuzu N-Series. Manual - part 475

Engine Mechanical (4HK1-TC) 6A-5

Crankshaft

Tuftriding is given, while on the No. 1 balance weight

imprinted is the grade of each journal diameter.

EGR System

Based upon data, including water temperature, engine

speeds or engine loads, it is controlled via Engine

Control Module (ECM) to purify exhaust by recycling

part of it.

Its main components include an EGR valve, an EGR

cooler and various sensors.

Connecting Rod Cap Bolt

The angular tightening method of the connecting rod

cap bolt further increases reliability and durability.

Common Rail-type Electronic Control Injection

System

The common rail-type electronic control injection

system is composed of a fuel supply pump that sets the

target pressure of high-pressure fuel and supply it, a

fuel rail that measures such high-pressure fuel and an

fuel injector that turns it into a fine spray and injects it.

Each is controlled via ECM based upon various

signals, while injection timing or fuel injection quantity

is controlled under every possible driving condition.

Fuel Injector

The fuel injector is a 7-hole nozzle that adjusts fuel

injection quantity or injection timing by opening or

closing an electromagnetic valve on the head of the

fuel injector.

ECM corrects the dispersion of fuel injection quantity

between fuel injectors according to ID code data in

memory. At the replacement of fuel injectors, ID code

data should be stored in ECM.

Fuel Filter with Sedimenter

It is a fuel filter with sedimenter that gets rid of water by

making use of the difference in specific gravity between

light oil and water, which comes with an indicator that

notifies you that it is filled with water.

Preheating System

The preheating system consists the ECM, the glow

relay, glow plugs and the glow indicator lamp. The

preheating system is operated when the engine coolant

temperature is low, and make the engine easy to start.

Lubrication System

It is an oil filter with full-flow bypass, which uses a

water-cool oil cooler and oil jet to cool the piston.

Functional Inspection

Inspection/adjustment of valve clearance

1. Inspection of valve clearance

a. Remove the cylinder head cover.

b. Remove the fuel injector harness assembly.

c. Loosen the terminal nuts alternately to remove.

d. Remove the leak-off pipe.

e. Rotate the crankshaft to make the No.1 cylinder

meet the compression top dead center (TDC).

Notice:

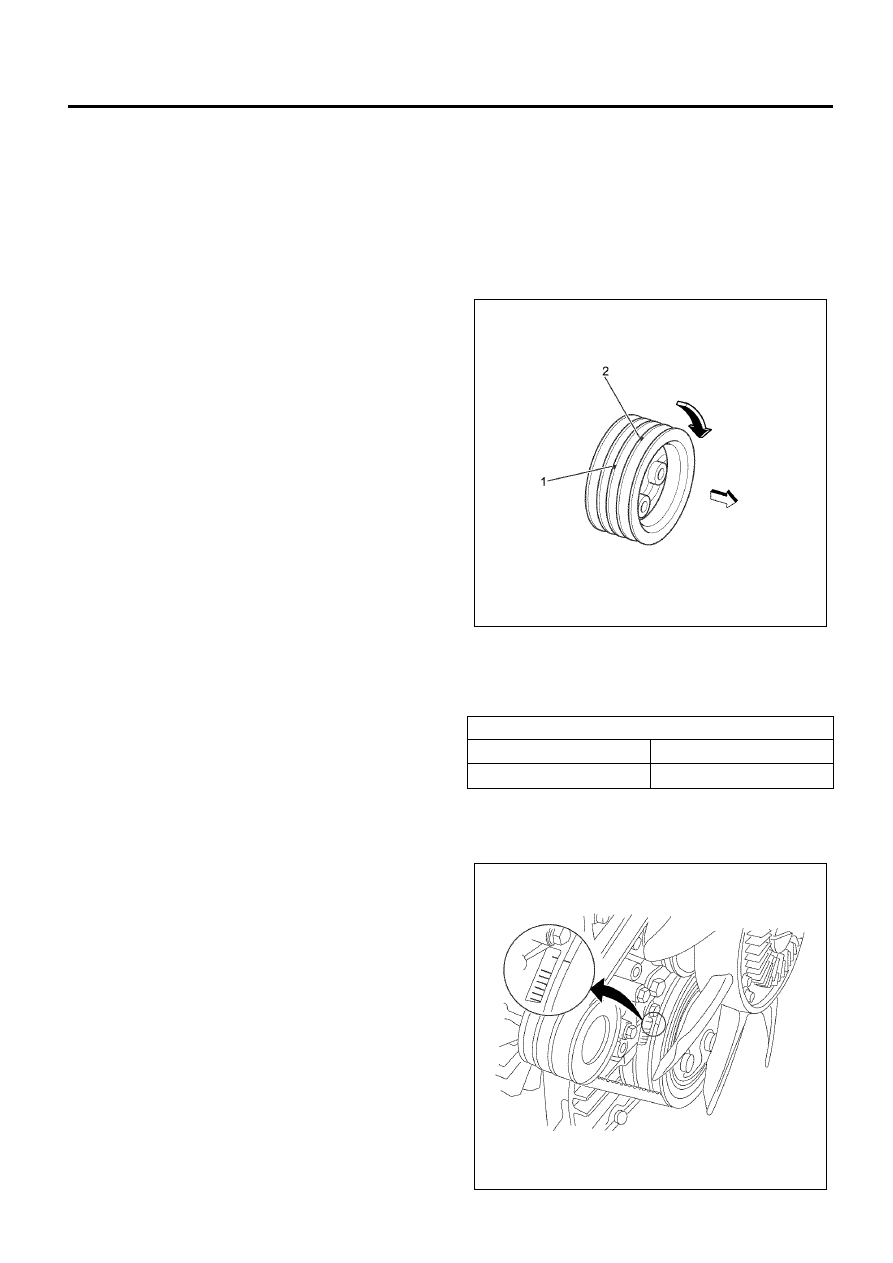

There are 2 timing marks on the crankshaft pulley.

Mark (1) is near the cylinder block and is used to bring

the 4HK1-TC engine to TDC.

Mark (2) is not applicable to this engine.

Be sure to use mark (1) when bringing the engine to

TDC.

• Insert a 0.4 mm (0.016 in) thickness gauge into

a clearance between the rocker arm and the

bridge to check it and adjust it if needed.

Caution:

Adjust while being cold.

Valve clearance

mm (in)

Intake valve

0.4 (0.016)

Exhaust valve

0.4 (0.016)

N6A6002E

N6A6003E