Isuzu N-Series. Manual - part 453

6E-148 EMISSION AND ELECTRICAL DIAGNOSIS

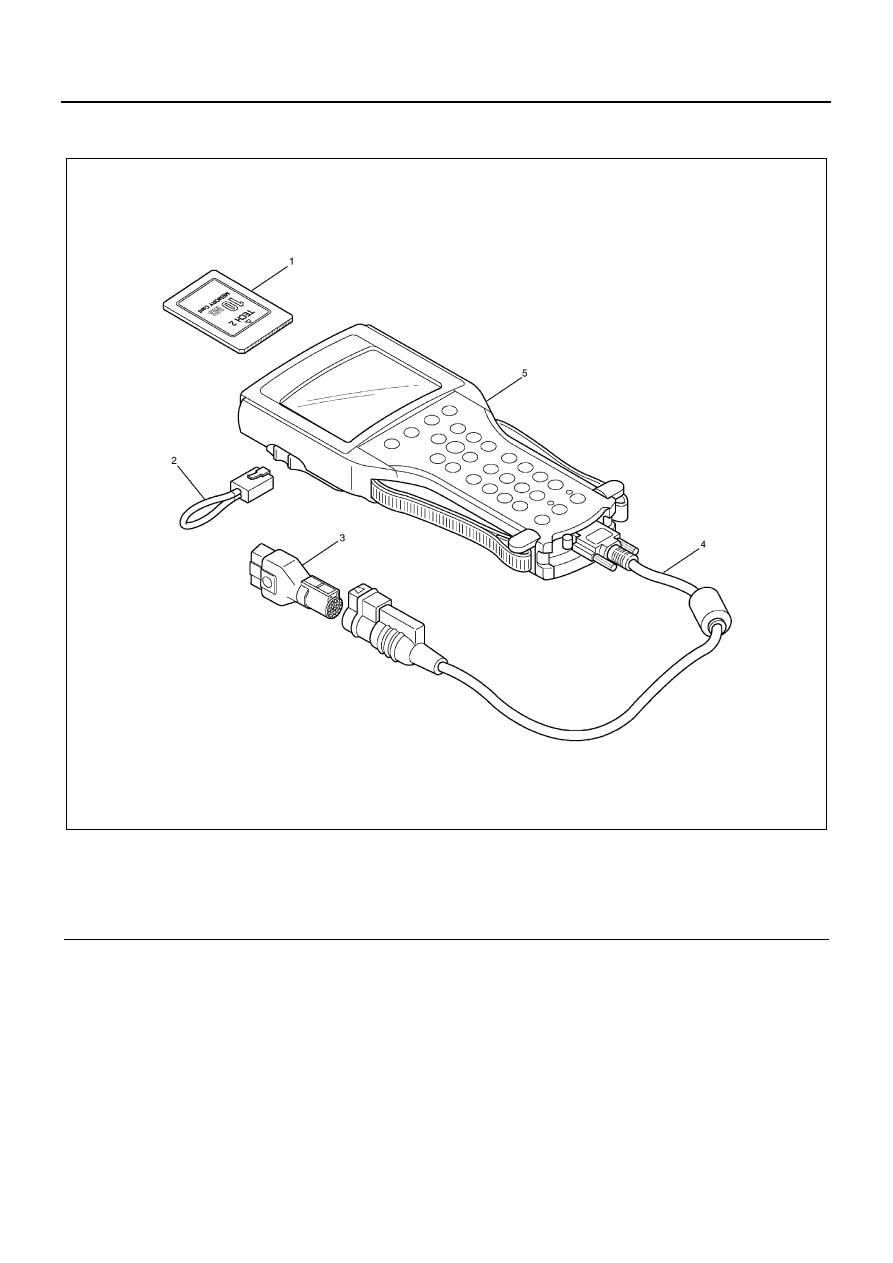

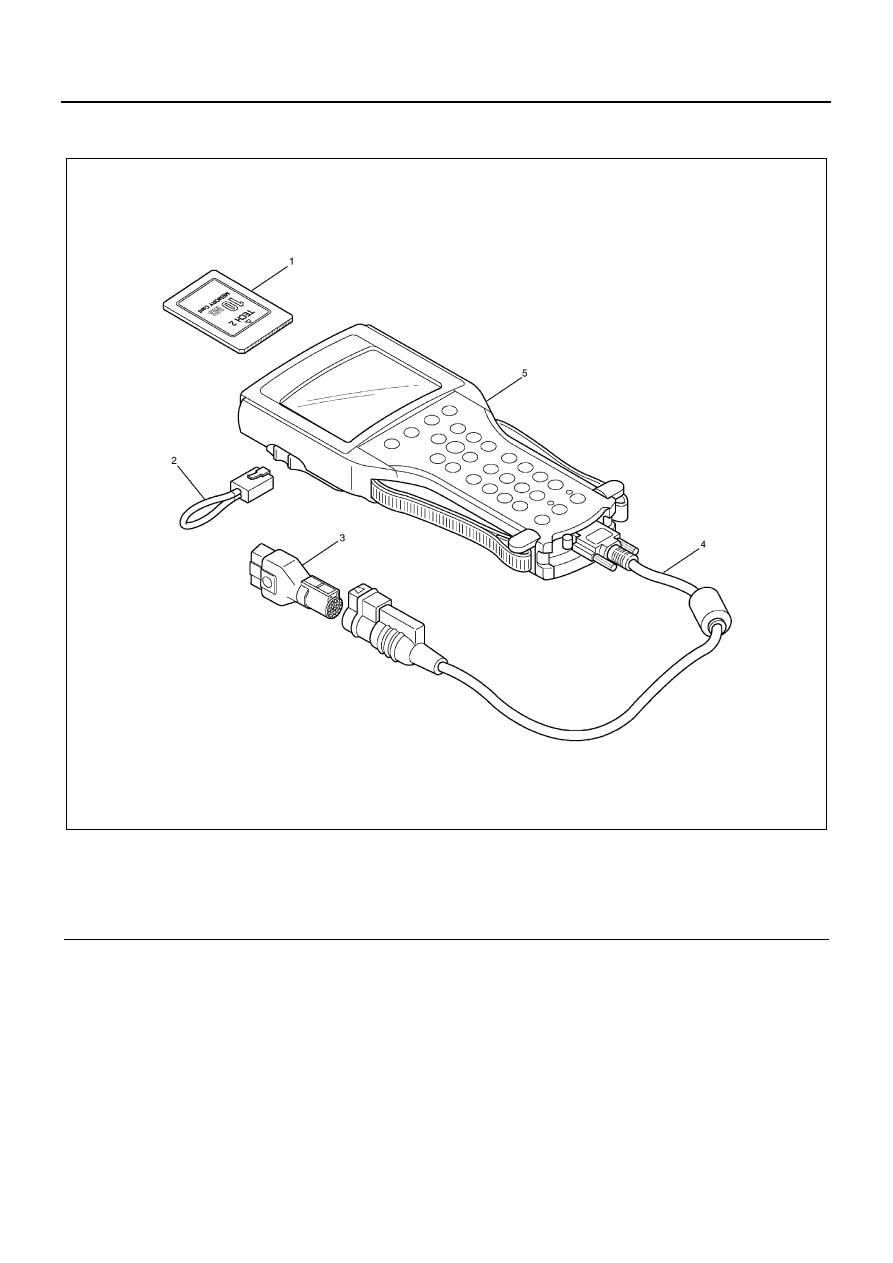

SPECIAL TOOLS

Legend

1. PCMCIA card

4. DLC cable

2. RS232 loop back connector

5. TECH-2

3. SAE 16/19 adapter

N6A1293E

|

|

|

6E-148 EMISSION AND ELECTRICAL DIAGNOSIS SPECIAL TOOLS Legend 1. PCMCIA card 4. DLC cable 2. RS232 loop back connector 5. TECH-2 3. SAE 16/19 adapter N6A1293E |