Isuzu N-Series. Manual - part 412

6D3-16 CHARGING SYSTEM

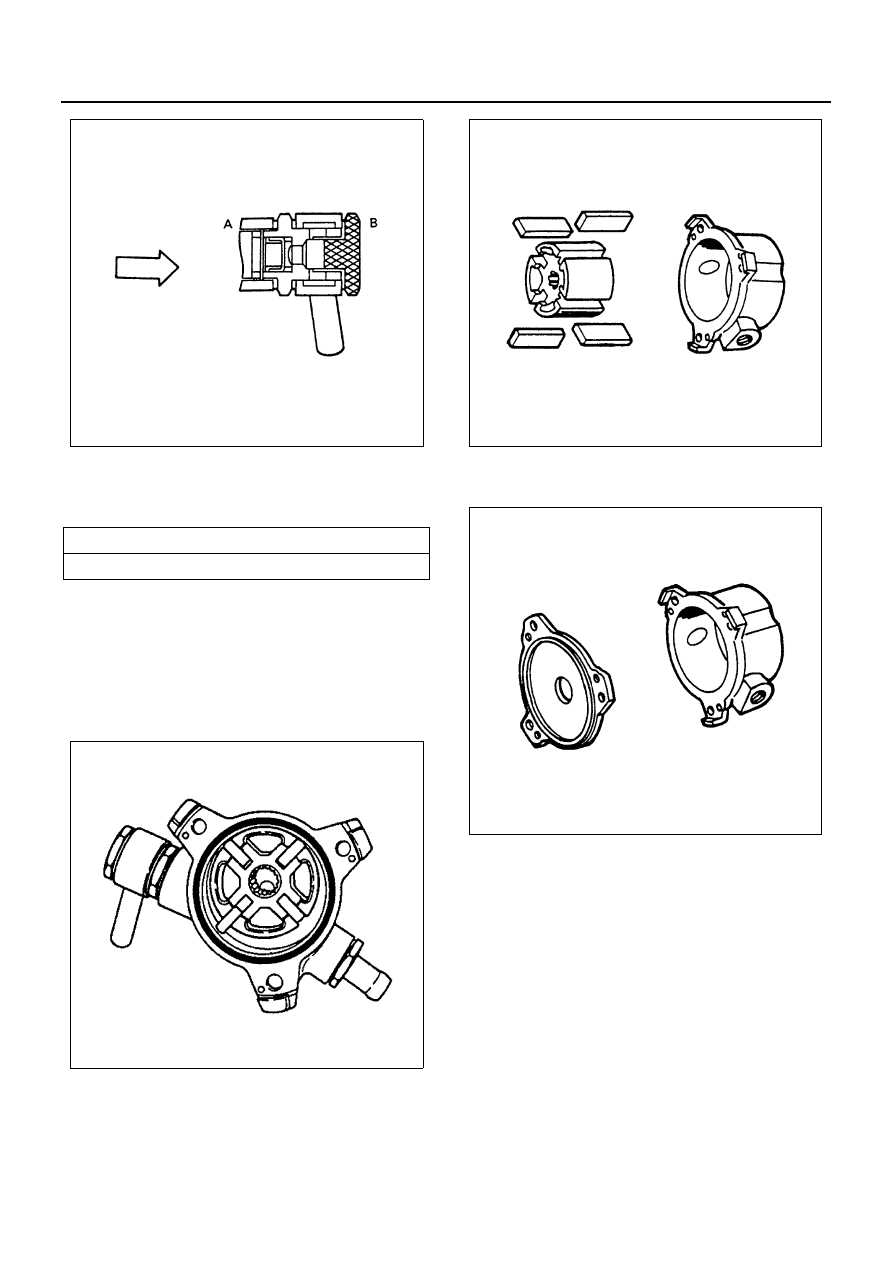

The valve must move smoothly.

If it does not, the check valve must be replaced.

2) Apply compressed air to the “A” side.

Check for air leakage from the check valve.

If there is air leakage, the valve must be re-

placed.

Reassembly

1. Install the vanes to the rotor slits.

The rounded side of the vanes must be facing the

rotor housing.

2. Install the rotor with the concave side facing the

center plate.

3. Install the center plate to the rotor housing.

Be sure to use a new O-rings.

Reassembly

1. Rear Cover

2. Brush and IC Regulator

3. Rectifier

4. Fan Guide

5. Stator

Air Pressure

kPa (kg/cm

2

/psi)

98 — 490 (1 — 5/14.22 — 71.10)

N6A1069E

N6A1070E

N6A1071E

N6A1067E