Isuzu N-Series. Manual - part 310

00-52 SERVICE INFORMATION

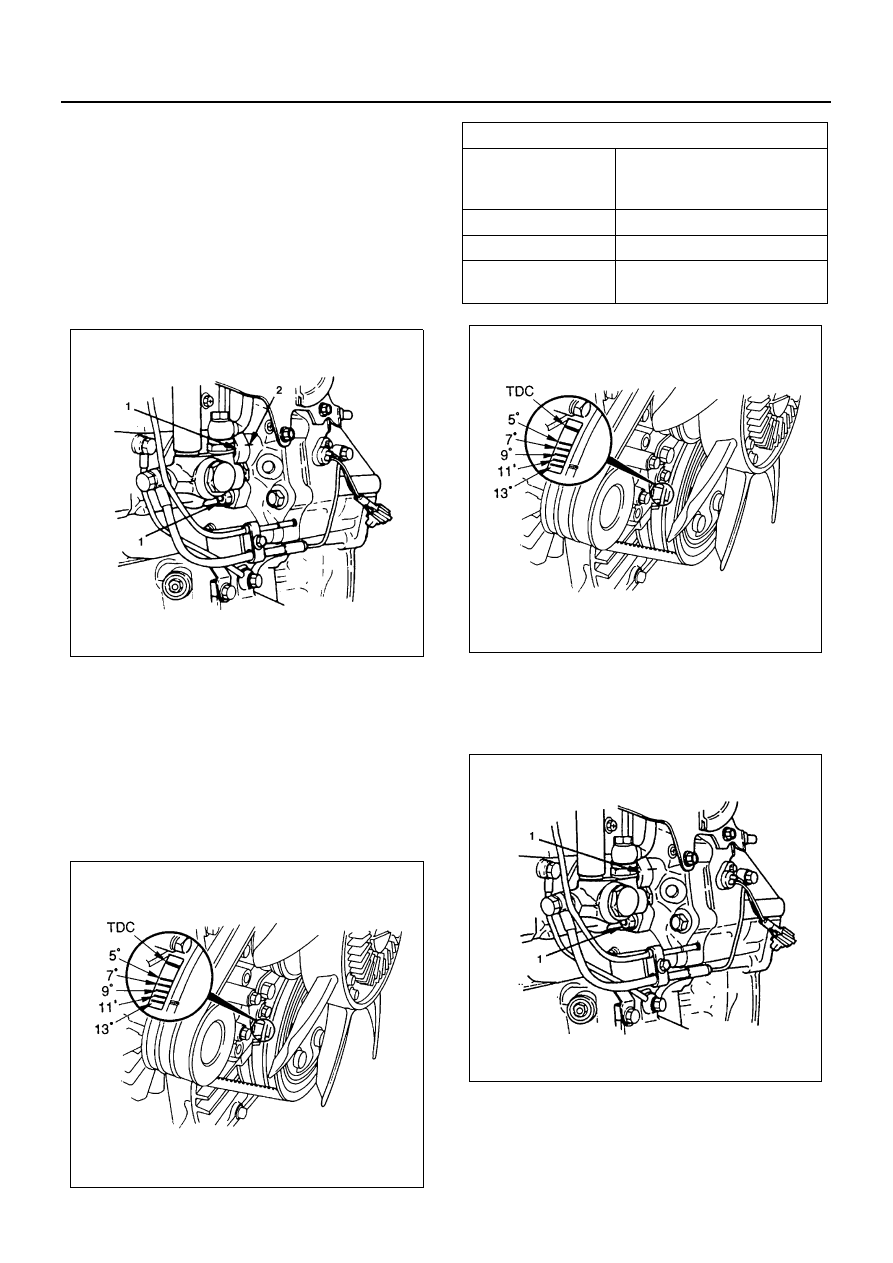

Injection Timing Adjustment

Injection Pump Notched Line Inspection

1. Check the injection pump bracket nuts (1) for

looseness.

Tighten as required.

2. Check that the notched lines (2) on the injection

pump bracket and the timing gear case are

aligned.

If the notched lines are not aligned, the injection

timing must be checked.

3. Some time, check injection timing on the crank

damper pulley.

If the injection timing aligned with in correct, the in-

jection timing must be readjusted.

Injection Timing Adjustment

1. Turn the crankshaft until the timing mark on the

crankshaft damper pulley is aligned with the BTDC

(injection timing of each engine model) mark in the

illustration.

2. Remove the two foam rubbers.

3. Loosen the four injection pump fixing nuts (1).

This will allow the pump to pivot.

Do not bend or scratch the fuel pipe.

4. Align the notched line between the injection pump

bracket and the timing gear case.

Make sure that the timing mark on the crank damp-

er pulley is aligned with correct injection timing.

N6A0050E

N6A0060E

Injection Timing

deg

4HF1

4HE1-TC

(4HE1-XS, XN)

BTDC 8

4HG1

BTDC 9

4HEI-T

BTDC 7

4HE1-TC

(4HE1-XS)

BTDC 9 (Spec EURO3)

N6A0060E

N6A0053E