Isuzu N-Series. Manual - part 221

HYDRAULIC BRAKES 5A-43

4. Correct any areas having poor contact with sand-

paper.

5. Repeat Steps 1 through 4 until the contact between

the brake lining and the brake drum is perfect.

Installation

1. Back Plate

Tighten the back plate bolts to the specified torque.

* Single Tire models

** Dual Tire models

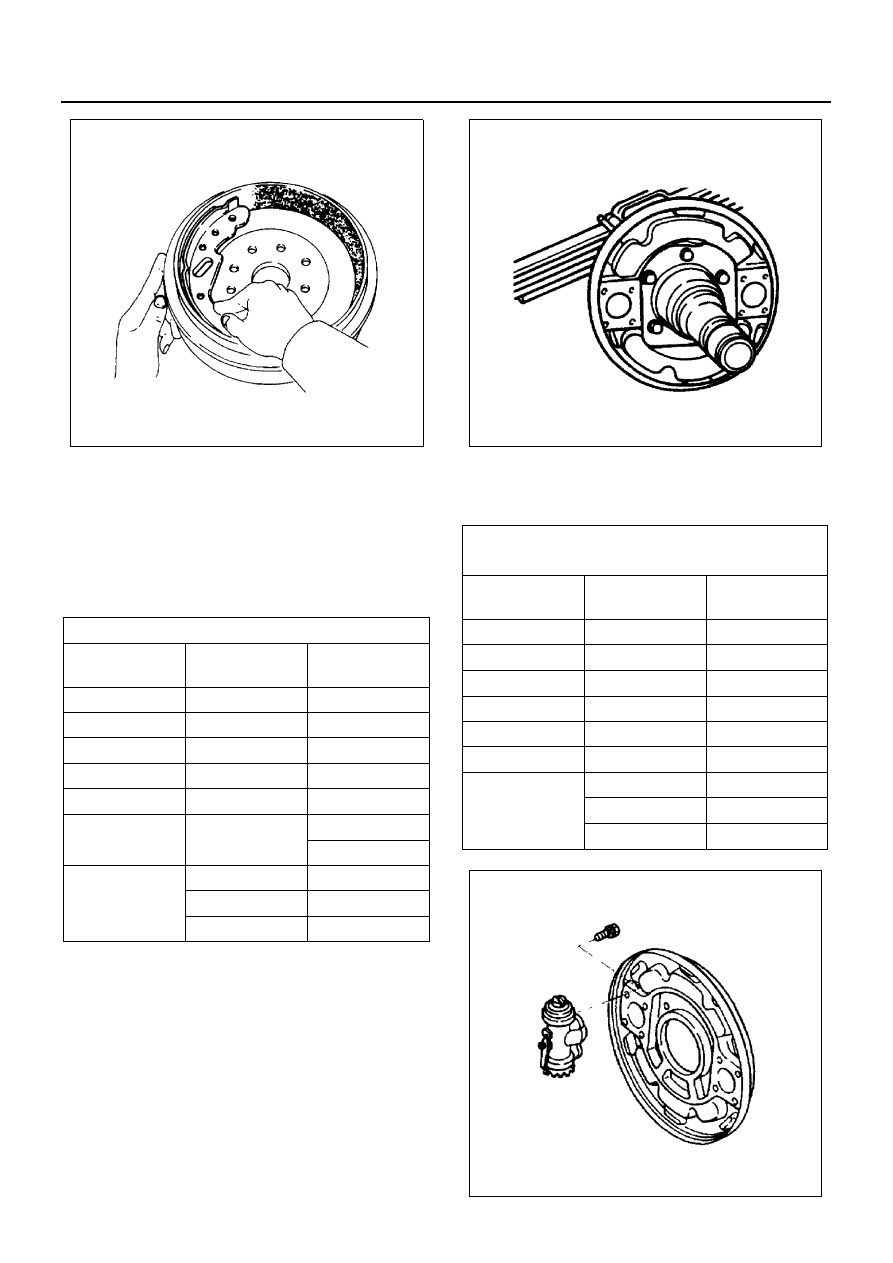

2. Wheel Cylinder Assembly

Tighten the wheel cylinder assembly bolts to the

specified torque.

Back Plate Bolt Torque

N

⋅m (kg⋅m/lb⋅ft)

Drum Inside

Dia. mm (in)

Lining

Width mm (in)

—

228.6 (9.00)

75 (2.95)

108 (11.0/80)

240.0 (9.45)

60 (2.36)

108 (11.0/80)

260.0 (10.24)

90 (3.54)

108 (11.0/80)

279.4 (11.00)

60 (2.36)

74 (7.5/54)

290.0 (11.42)

75 (2.95)

108 (11.0/80)

300.0 (11.81)

75 (2.95)

* 44 (4.5/33)

** 108 (11.0/80)

320.0 (12.60)

75 (2.95)

108 (11.0/80)

100 (3.94)

108 (11.0/80)

120 (4.72)

157 (16.0/116)

N5A0142E

Wheel Cylinder Assembly Bolt Torque

N

⋅m (kg⋅m/lb⋅ft)

Drum Inside

Dia. mm (in)

Lining

Width mm (in)

—

228.6 (9.00)

75 (2.95)

34 (3.5/25)

240.0 (9.45)

60 (2.36)

25 (2.5/18)

260.0 (10.24)

90 (3.54)

43 (4.4/32)

279.4 (11.00)

60 (2.36)

27 (2.8/20)

290.0 (11.42)

75 (2.95)

25 (2.5/18)

300.0 (11.81)

75 (2.95)

34 (3.5/25)

320.0 (12.60)

75 (2.95)

43 (4.4/32)

100 (3.94)

74 (7.5/55)

120 (4.72)

94 (9.6/69)

N5A0173E

N5A0146E