Isuzu N-Series. Manual - part 175

REAR AXLE 4B-57

The viscous-type limited slip differential is of the struc-

ture filled with viscous (high viscosity silicone oil) be-

tween the outer plates connected to the differential case

and the inner plates connected to the side gear on the

left side. While driving, the difference in the number of

revolutions between the right and left wheels causes the

difference in the number of revolutions also between the

differential case and the side gear on the left side. This

difference in the number of revolutions results in shear-

ing of silicone oil to generate viscous torque between

the plates.

When either one of the wheels is caught up in muddy or

snow melting road and starts racing while driving, the

operation of the viscous torque mentioned above makes

it facilitate to drive the vehicle by providing a driving

force to the other wheel on the road where the road con-

dition is better.

Caution:

The LSD assembly cannot be disassembled. When

there occurs anything abnormal with the LSD assembly,

replace it as an assembly. (Please note that when the

silicone oil which has been sealed inside drains out

while in disassembly, the LSD assembly will fail to dis-

play its intrinsic performance.)

Performance Check (Except Taiwan, Australia and

GCC)

Check the performance by following the procedure giv-

en below.

1. Set the transmission gearshift lever to the neutral

position.

2. Lift up the rear axle.

3. Rotate with a gathered momentum either one of

the wheels on the rear axle in the forward direction.

When the wheel on the opposite side rotates in the for-

ward direction while in the operation of (3) above, it is

considered that the performance of viscous coupling

functions normally, and otherwise, that the viscous cou-

pling has a lowered performance.

Warning:

WARNING:

WHEN EITHER ONE OF THE REAR WHEELS IS LIFT-

ED UP AND A DRIVING FORCE IS APPLIED TO THE

REAR AXLE, THE VEHICLE IS IN DANGER OF

STARTING ABRUPTLY. BE SURE NOT TO APPLY A

DRIVING FORCE TO THE REAR AXLE IN THIS CON-

DITION.

For detailed information of disassembling, assembling,

checking and servicing of parts other than the LSD as-

sembly, refer to “292 MM DIFFERENTIAL”.

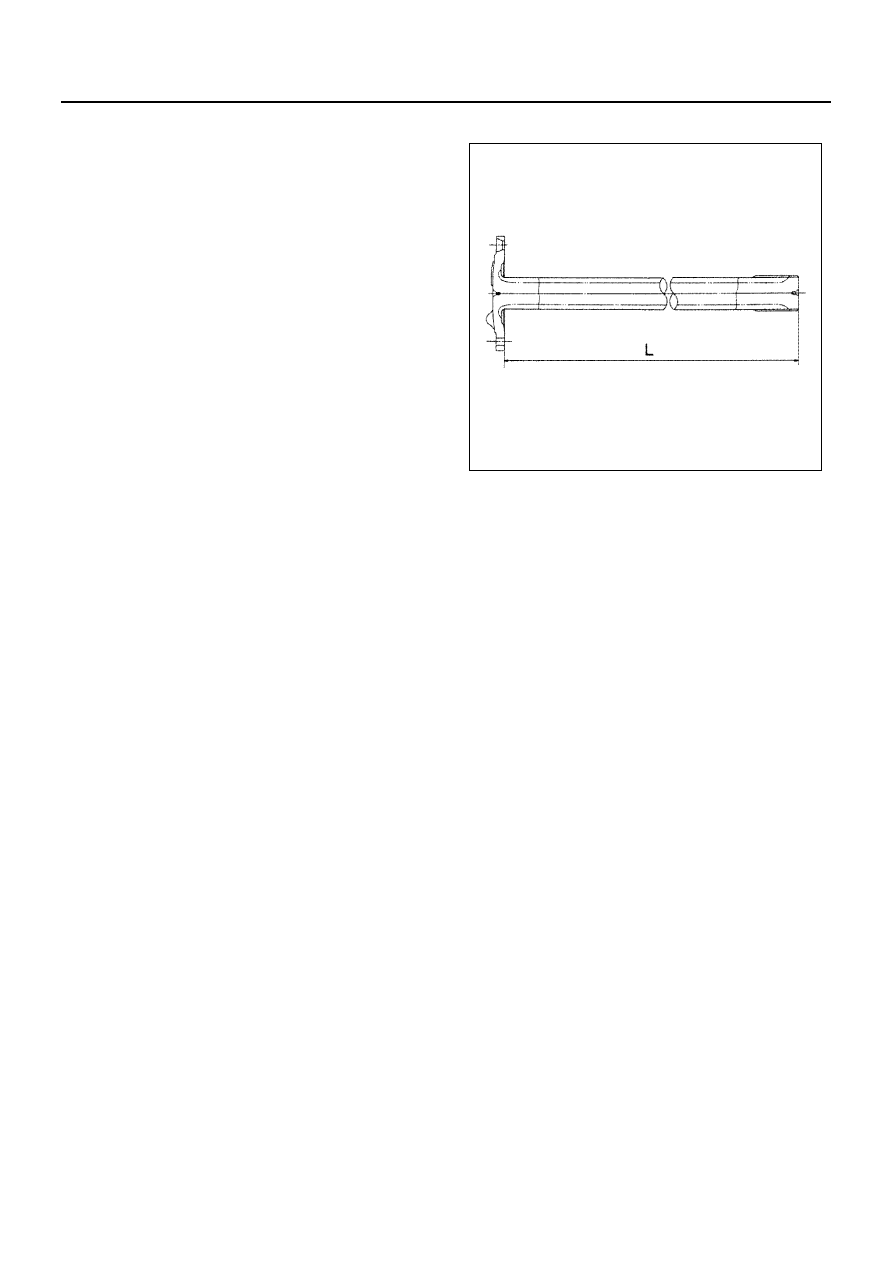

Rear Axle Shaft (Except 2003 year model)

Notice:

For vehicles provided with the LSD assembly, the length

of the rear axle shafts is different from each other on the

right and left sides. Be careful not to confuse one with

another when replacing the rear axle shaft.

L (in the illustration)

Right side: 800

± 2 mm (31.5 ± 0.08 in)

Left side: 856

± 2 mm (33.7 ± 0.08 in)

N4A0208E