Content .. 1154 1155 1156 1157 ..

Isuzu N-Series. Manual - part 1156

8-336 CAB AND CHASSIS ELECTRICAL

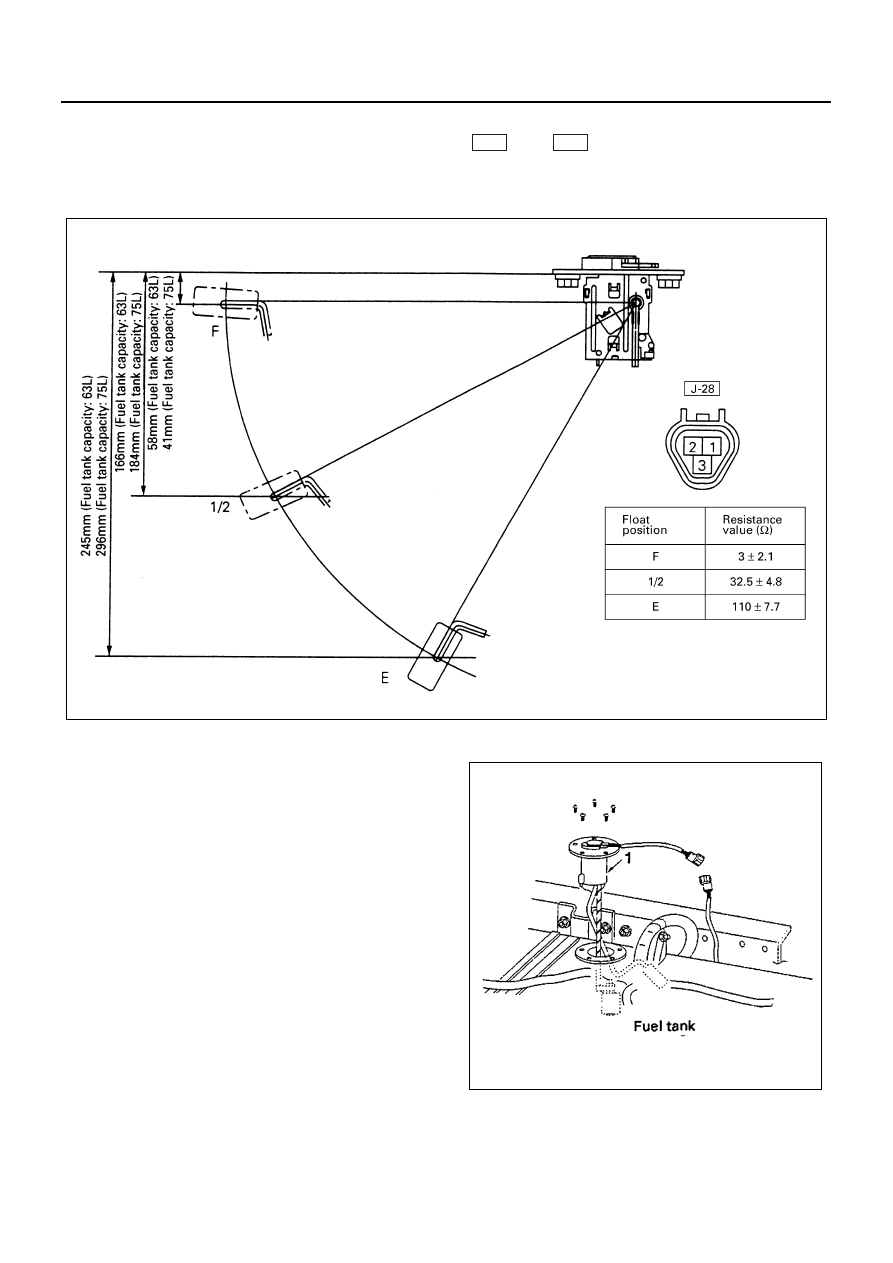

(Float type of warn low fuel level)

1. Check the resistance between the connector terminals 1

and 3

while shifting the float from “E” to “F”

point.

2. Check if the low fuel warning light turns on when the float is at “E” position. If found defective replace the fuel

tank unit.

Removal

Preparation:

Disconnect the battery ground cable.

1. Fuel Tank Unit

1) Disconnect the connector.

2) Remove five screws.

Installation

To install, follow the removal steps in the reverse order.

J-28

J-28

N8A5414E

N8A5415E