Content .. 1052 1053 1054 1055 ..

Isuzu N-Series. Manual - part 1054

CAB AND CHASSIS ELECTRICAL 8-321

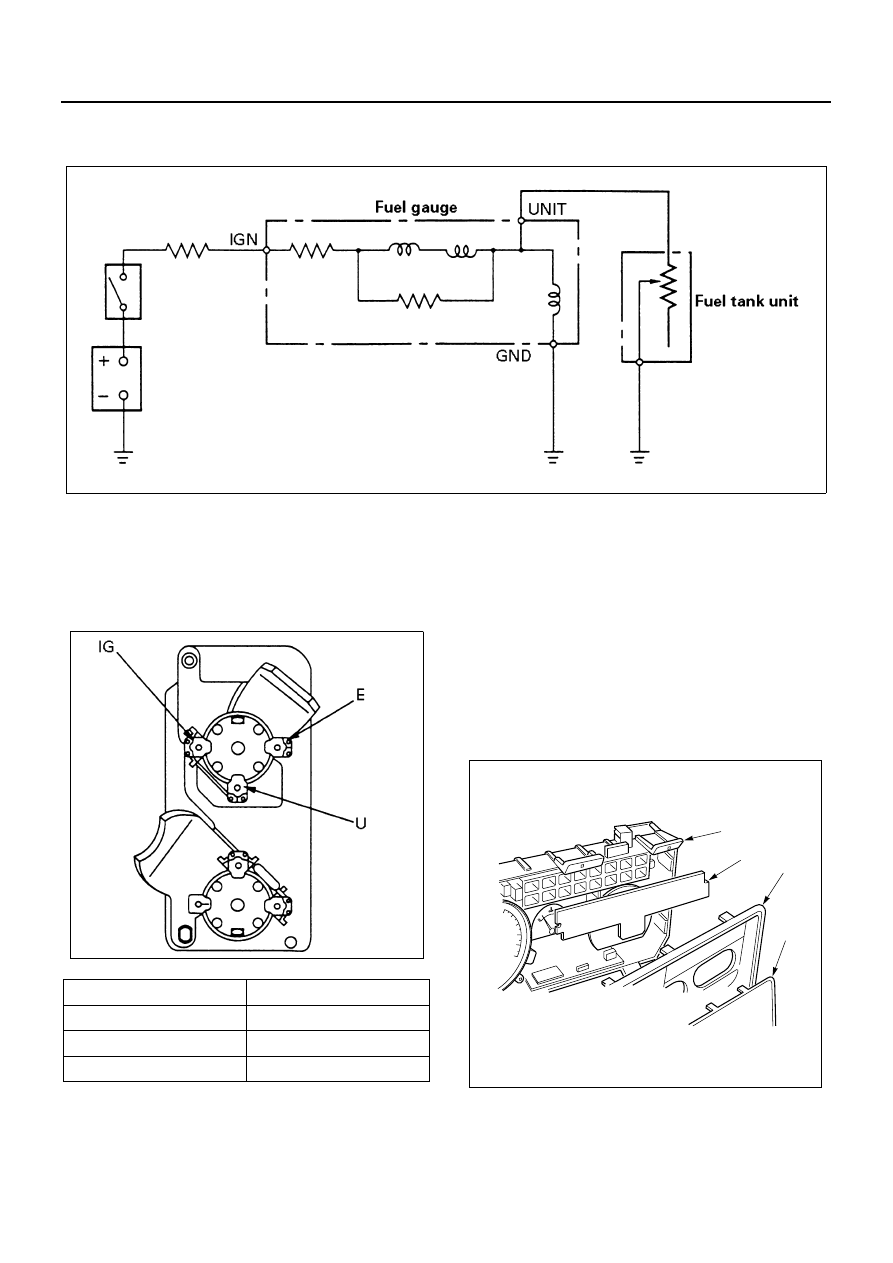

Fuel Gauge

Circuit Diagram

Inspection

Remove the fuel gauge from the meter assembly, and

measure the resistance value between each terminal.

Replace the meter when the result of inspection is found

abnormal.

Removal and Installation

Refer to the “COOLANT TEMPERATURE GAUGE” in

this section.

Warning Lens

Removal

Preparation:

Disconnect the battery ground cable.

1. Meter Assembly

Refer to “METER ASSEMBLY” in this section.

2. Meter Glass

Remove it by pushing the catches with your finger.

3. Meter Plate

Remove it by pushing the catches with your finger.

4. Warning Lens

N8A0341E

Terminal symbol

Resistance value

IG — U

108.1

Ω±10%

U — E

103

Ω±10%

IG — E

211.1

Ω±10%

N8A0342E

3

2

1

4

N8A5404E