Isuzu N-Series. Manual - part 58

1B-2 AIR CONDITIONING

GENERAL DESCRIPTION

Caution:

This Vehicle is equipped with Refrigerant-134a (R-134a) air conditioning system.

R-134a and A-12 systems require different types of lubricating oil. Components designed solely for use with one re-

frigerant and oil type must never be interchanged with components designed solely for use with another refrigerant

and oil type. Refer to “ON-VEHICLE SERVICE” for Precautions for R-134a Air Conditioning system in this section.

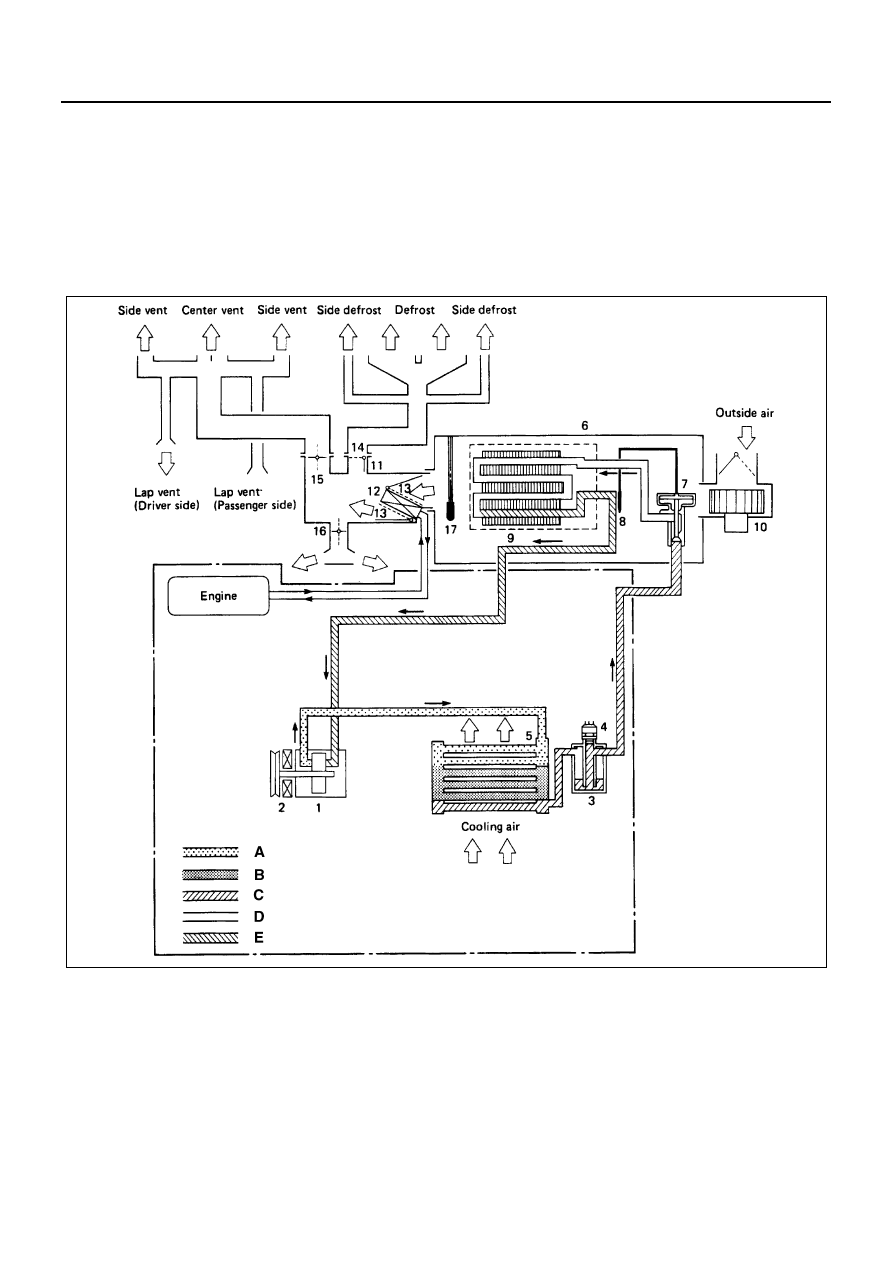

Air Conditioning Refrigerant Cycle Construction

N1A0045E