Isuzu Rodeo UE. Manual - part 649

9J1–33

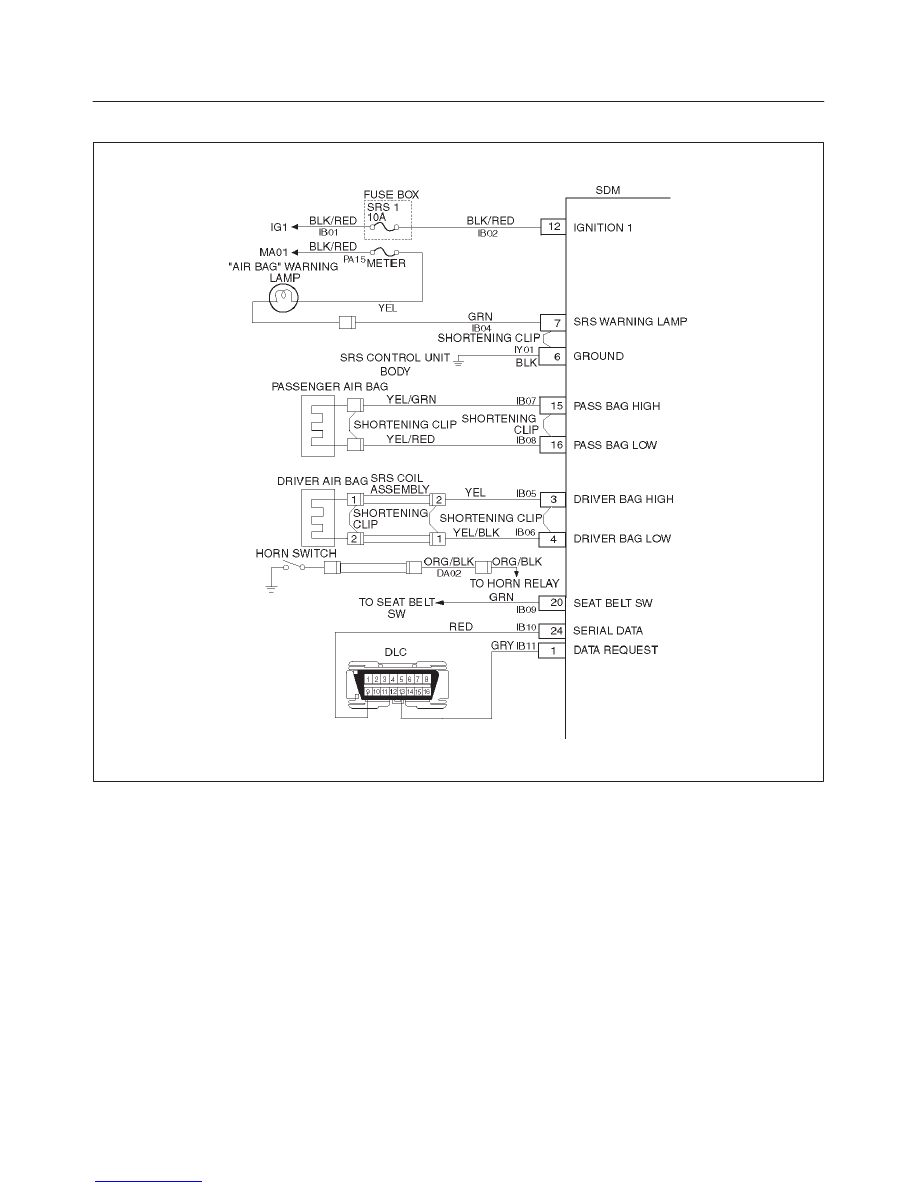

RESTRAINT CONTROL SYSTEM

DTC 25 Driver Deployment Loop Short To Voltage

D09RW002

Circuit Description:

When the ignition switch is turned “ON”, the SDM will

perform tests to diagnose critical malfunctions within

itself. Upon passing these tests, “ignition 1”, and

deployment loop voltages are measured to ensure they

are within their respective normal voltage ranges.

The SDM monitors the voltage at “Driver Bag Low”

terminal “4” and “Passenger Bag Low” terminal “16” to

detect shorts to B+ in the air bag assembly circuits.

DTC Will Set When:

“Ignition 1” is in the normal operating voltage range. This

test is run once each ignition cycle and “Continuous

Monitoring”. Once these conditions are met and the

voltage at “Driver Bag Low” is above a specified value,

DTC 25 will set.

Action Taken:

SDM turns “ON” the “AIR BAG” warning lamp and sets

DTC 25 and also DTC 71

DTC Will Clear When:

The SDM is replaced.

DTC Chart Test Description:

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the SDM is

malfunctioning.

3. This test isolates the malfunction to one side of the

SRS coil assembly yellow 2–pin connector at the

base of steering column.

4. This test determines whether the malfunction is in

CKT IB05–YEL.

5. This test determines whether the malfunction is in

CKT IB06–YEL/BLK.