Isuzu Rodeo UE. Manual - part 524

CLUTCH

7C–19

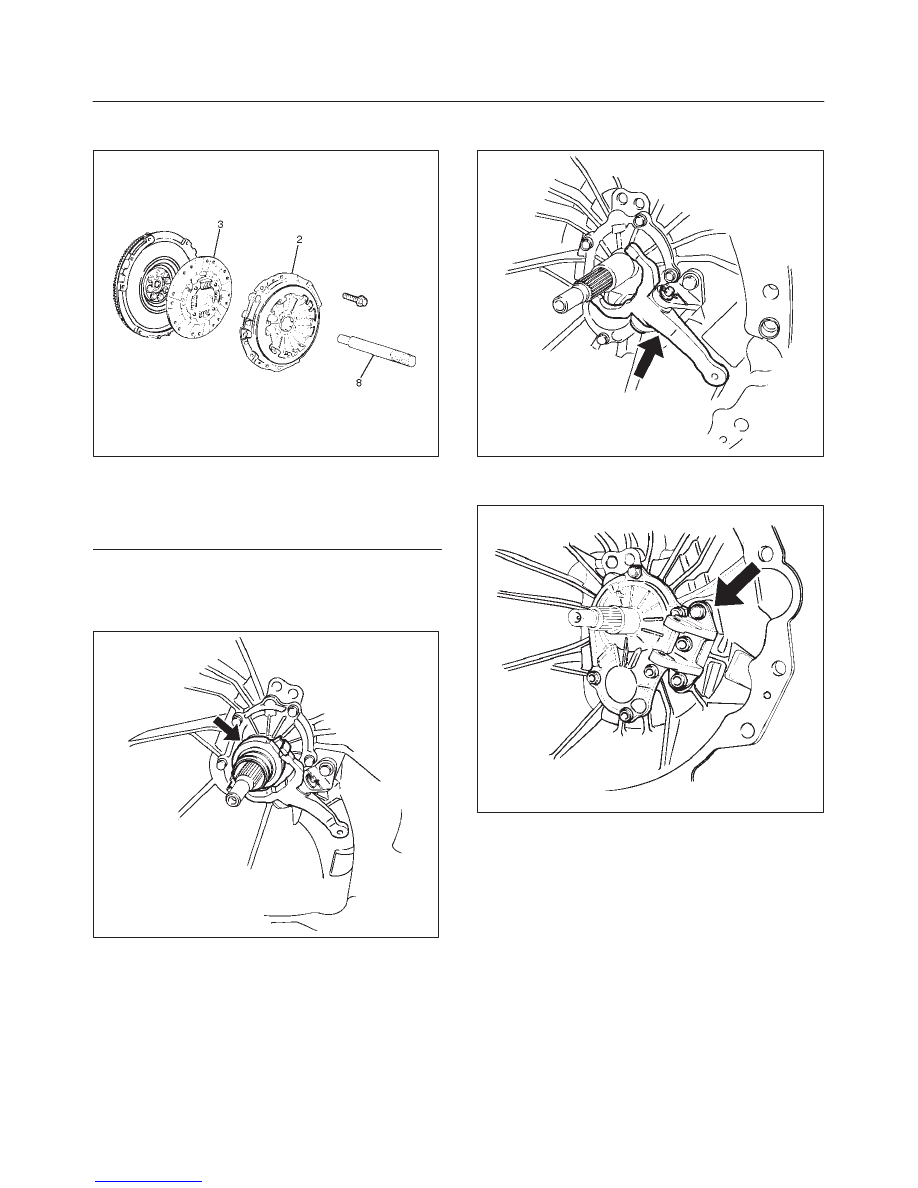

2. Use the pilot aligner J24547 to prevent the driven

plate assembly (3) from falling free.

201RS001

Legend

(2) Pressure Plate Assembly

(3) Driven Plate Assembly

(8) Pilot Aligner

3. Mark the flywheel, clutch cover and pressure plate lug

for alignment when installing.

4. Remove the release bearing (4) from the

transmission case.

201RS024

5. Remove the snap pin. Remove the shift fork pin and

shift fork from the fulcrum bridge.

201RS025

6. Remove the fulcrum bridge bolts. Remove the

fulcrum bridge (6) from the transmission case.

201RS026