Isuzu Rodeo UE. Manual - part 328

6E2–67

RODEO 6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

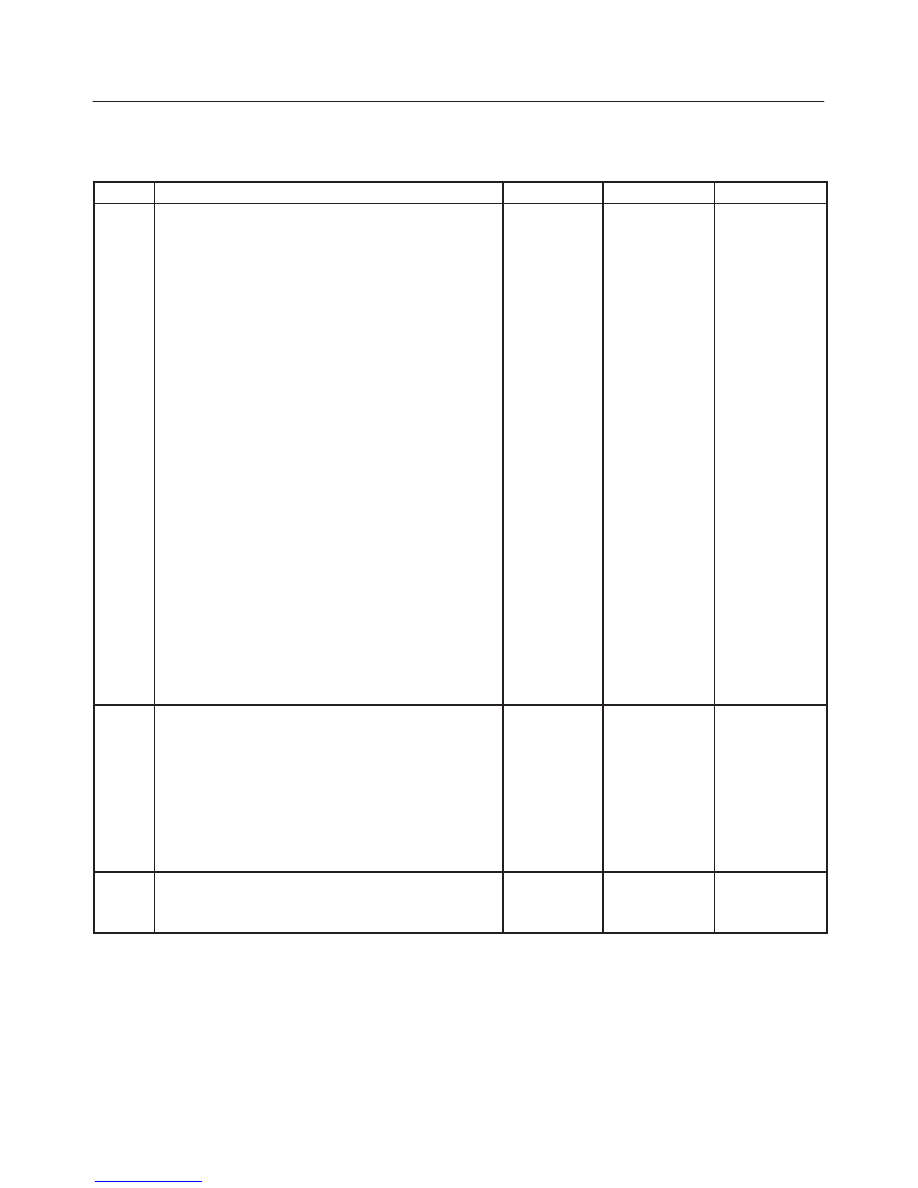

Injector Coil Test Procedure (Steps 1-6) and Injector Balance Test Procedure

(Steps 7-11)

(Cont'd)

Step

No

Yes

Value(s)

Action

9

1. Connect the J 39021-5V Fuel Injector Tester and J

39021-90 Injector Switch Box the fuel injector

harness connector.

2. Set the amperage supply selector switch on the fuel

injector tester to the “Balance Test” 0.5-2.5 amp

position.

3. Using the Tech 2 turn the fuel pump “ON” then

“OFF” in order to pressurize the fuel system.

4. Record the fuel pressure indicated by the fuel

pressure gauge after the fuel pressure stabilizes.

This is the first pressure reading.

5. Energize the fuel injector by depressing the “Push

to Start Test” button on the fuel injector tester.

6. Record the fuel pressure indicated by the fuel

pressure gauge after the fuel pressure gauge

needle has stopped moving. This is the second

pressure reading.

7. Repeat steps 1 through 6 for each fuel injector.

8. Subtract the second pressure reading from the first

pressure reading for one fuel injector. The result is

the pressure drop value.

9. Obtain a pressure drop value for each fuel injector.

10.Add all of the individual pressure drop values. This

is the total pressure drop.

11. Divide the total pressure drop by the number of fuel

injectors. This is the average pressure drop.

Does any fuel injector have a pressure drop value that

is either higher than the average pressure drop or lower

than the average pressure drop by the specified value?

10 kPa (1.5

psi)

Go to

Step 10

Go to

OBD

System

Check

10

Re-test any fuel injector that does not meet the

specification. Refer to the procedure in step 9.

NOTE: Do not repeat any portion of this test before

running the engine in order to prevent the engine from

flooding.

Does any fuel injector still have a pressure drop value

that is either higher than the average pressure drop or

lower than the average pressure drop by the specified

value?

10 kPa (1.5

psi)

Go to

Step 11

Go to

Symptoms

11

Replace the faulty fuel injector(s). Refer to

Fuel

Injector.

Is the action complete?

—

Verify repair

—