Isuzu Rodeo UE. Manual - part 156

6D3–9

STARTING AND CHARGING SYSTEM (X22SE 2.2L)

Generator Power

1. Adjust load resistor, if the required load currents are

not attained.

2. The shape of the voltage curves on oscilloscope

curve should be regular.

3. Test value: 5 to 7A.

4. If the required minimum current intensity is not

attained, or if the oscilloscope picture shows

variations, the alternator should be overhauled.

066RW018

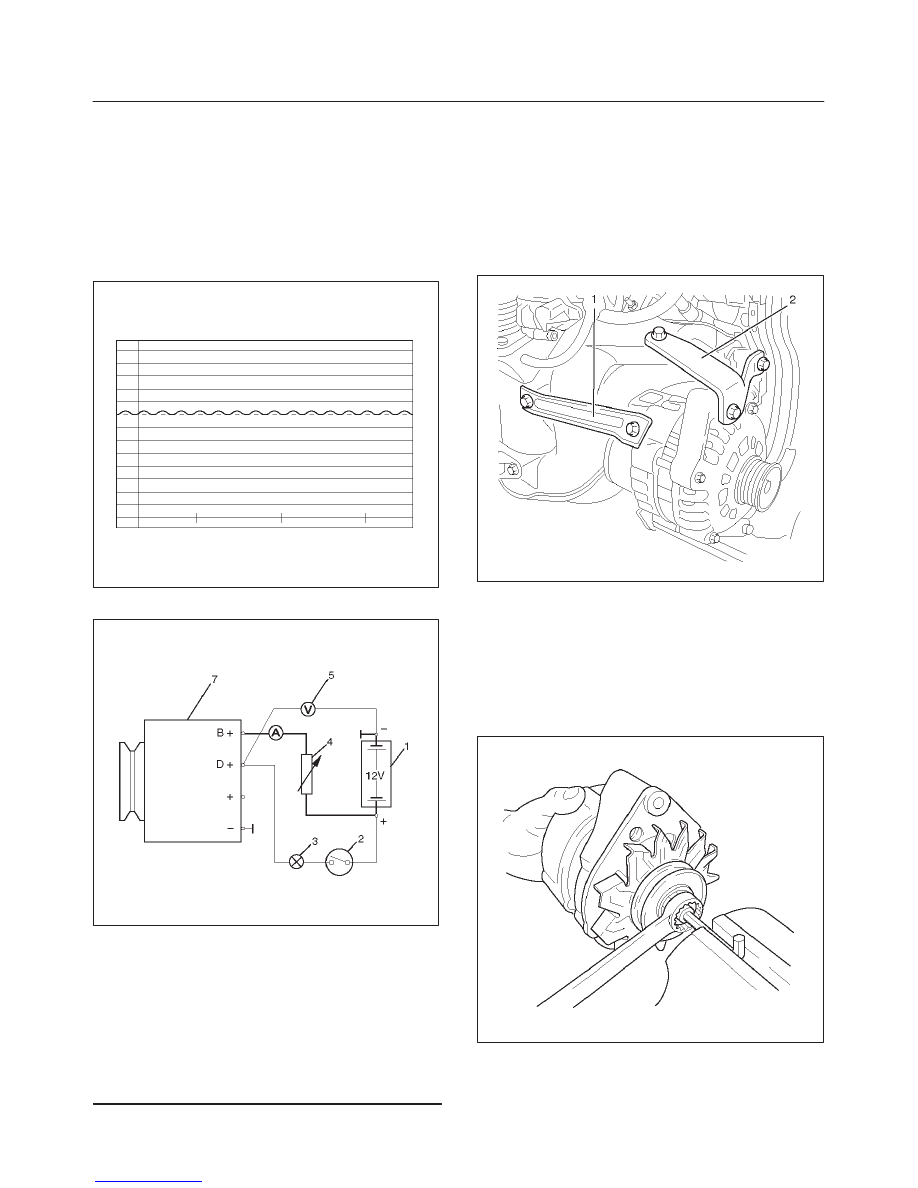

Regulated Voltage Circuit Diagram

066RW019

Legend

(1) Battery

(2) Ignition Lock

(3) Charge Telltale

(4) Resistor, for attainment of load current with the

battery set in series

(5) Voltmeter

(6) Ammeter

(7) Generator

Installation

1. Install generator assembly and bring generator

assembly to the position to be installed.

2. Install generator bracket (1), (2) and tighten to the

specified torque.

Torque:

Long bolt: 35 N·m (26 lb ft)

Short bolt: 20 N·m (15 lb ft)

065RW025

3. Connect wiring harness connector.

4. Move drive belt tensioner to loose side using wrench,

then install drive belt to normal position.

5. Reconnect battery ground cable.

Disassembly

1. Belt pulley nut.

066RW016