Isuzu Rodeo UE. Manual - part 140

6A–49

ENGINE MECHANICAL (X22SE 2.2L)

Crankshaft (12) Inspection

Inspect the surface of the crankshaft journal and crank

pins for excessive wear and damage. Inspect the oil seal

fitting surfaces for excessive wear and damage. Inspect

the oil ports for obstructions.

Inspection and Repair

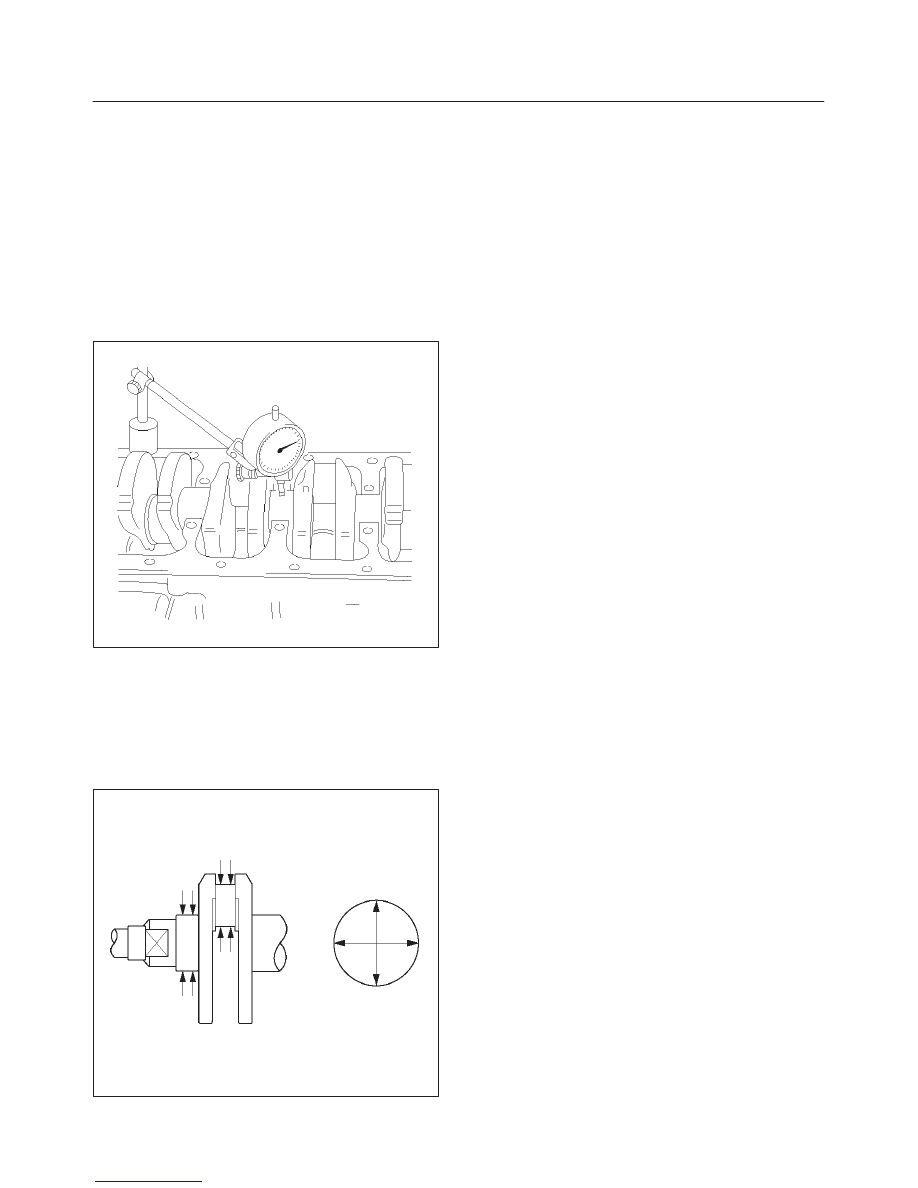

1. Carefully set the crankshaft. Slowly rotate the

crankshaft and measure the runout. If the crankshaft

runout exceeds the specified limit, the crankshaft

must be replaced.

Runout : 0.03 mm (0.0012 in)

014RW078

2. Measure the diameter and the uneven wear of main

journal and crank pin. If the crankshaft wear exceeds

the specified limit, crankshaft must be replaced.

Main journal diameter : 57.934 mm–57.980 mm

(2.259 in–2.261 in)

Crank pin diameter : 48.939 mm–48.982 mm

(1.909 in.–1.91 in.)

015RS009