Isuzu Rodeo UE. Manual - part 71

4B–15

DRIVELINE CONTROL SYSTEM

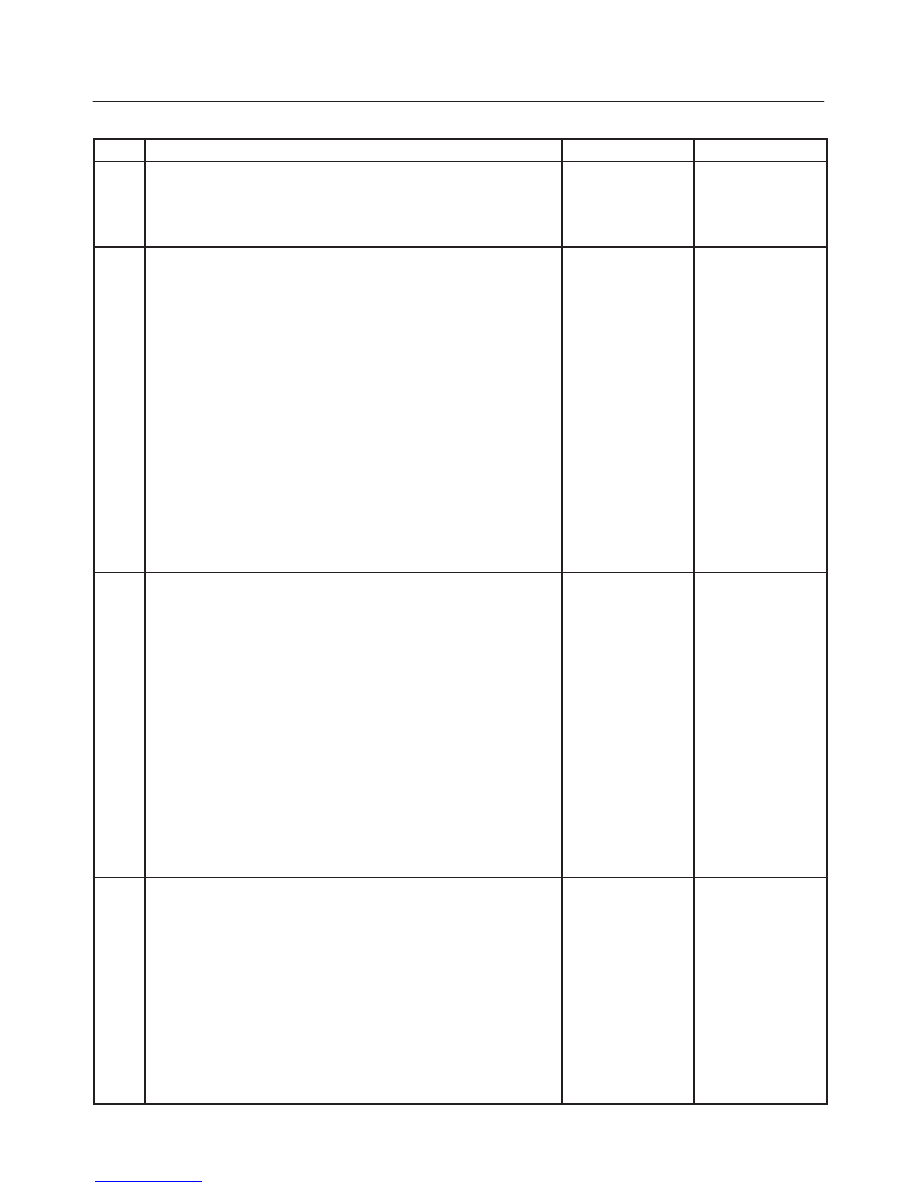

2. Case that indicator keeps 2Hz blinking after aforementioned Solution 3 is carried out.

Step

Action

Yes

No

1

Check the air pressure and wear of all tires.

Were problems found?

Try Solution 3

after adjust the

air pressure and

replace worn

tires.

Go to Step 2

2

Can the transfer lever be operated from High to 4L or vice versa?

Faults on the

harness wiring of

motor actuator.

Trace this chart

from the start

after repair or

replace.

Internal faults on

transfer case.

Disassemble the

transfer case for

check. Trace this

chart from the

start after repair

or replace.

Faults on the

motor actuator.

Trace this chart

from the start

after or replace.

Go to Step 3

3

Pull out the hoses from vacuum actuator and operate 4WD

switch.

Is there negative pressure on either of hoses?

Go to Step 4

Faults on the

transfer position

switch or its

harness. Trace

this chart from

the start after

repair or replace.

Faults on the

VSV main body,

its harness or

vacuuming

system. Trace

the diagnosis

chart in Front

Axle ASM

section. After

that, trace this

chart from the

start.

4

Check the axle switch.

Were problems found?

Internal faults on

axle switch.

Trace this chart

from the start

after replace.

Faults on Front

Axle ASM. Trace

the diagnosis

chart in Front

Axle ASM

section. After

that, trace this

chart from the

start.

Short circuit

(body short) or

disconnection of

the axle harness.

Trace this chart

from the start

after repair or

replace.