Isuzu Rodeo UE. Manual - part 67

DIFFERENTIAL (REAR)

4A2–33

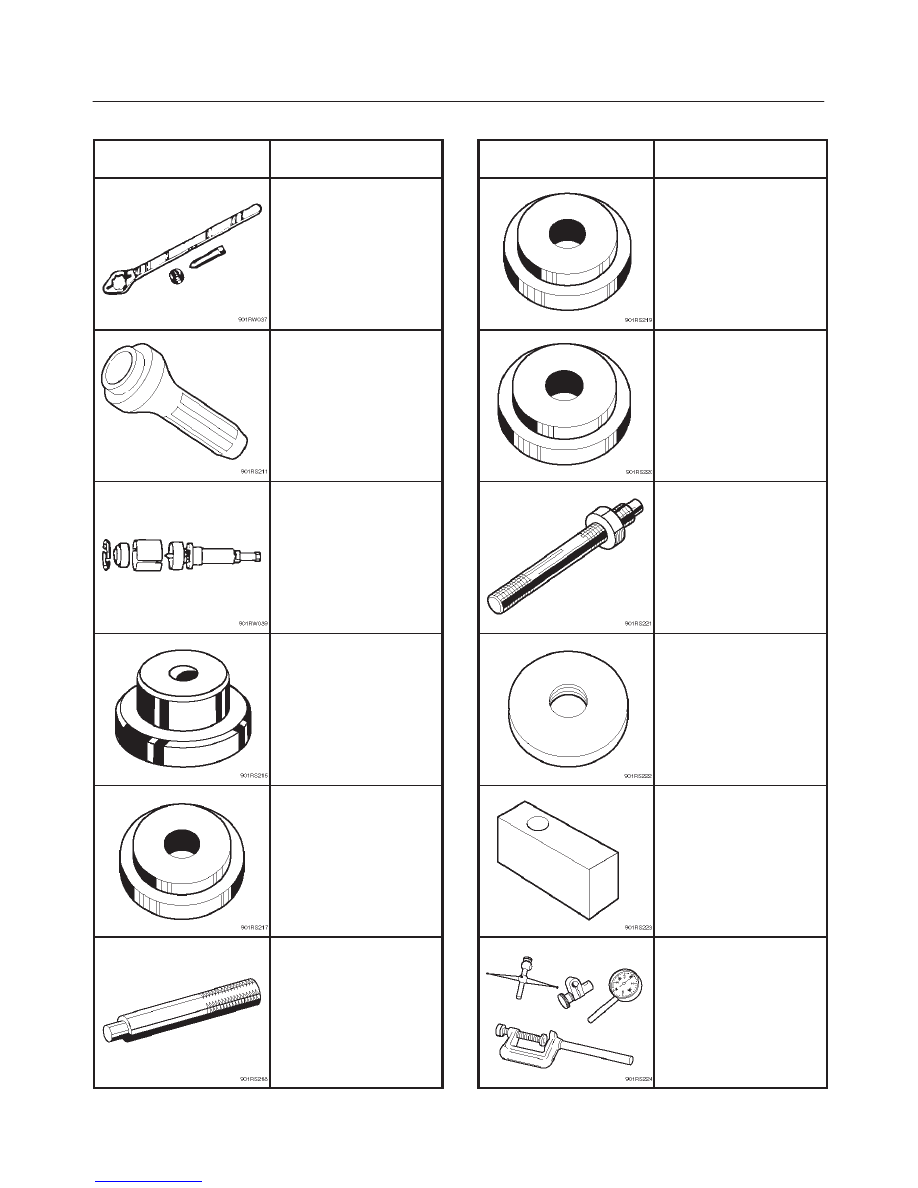

Special Tools

ILLUSTRATION

TOOL NO.

TOOL NAME

J–8614–01

Pinion flange holder

J–37263

Installer; Pinion oil seal

J–42379

Remover; Bearing

J–39830

Adapter; Side bearing

plug

J–8611–01

Installer; Outer bearing

outer race

J–8592

Grip

ILLUSTRATION

TOOL NO.

TOOL NAME

J–42836

Installer; Inner bearing

outer race

J–42824

Pilot;Outer

J–21777–43

Nut & Stud

J–42827

Pilot;Inner

J–39837–2

Gauge plate

J–8001

Dial indicator