Isuzu Rodeo UE. Manual - part 37

2A–44 POWER–ASSISTED STEERING SYSTEM

5. Remove the engine hood opening lever, then remove

instrument panel lower cover.

6. Remove driver knee bolster (reinforcement).

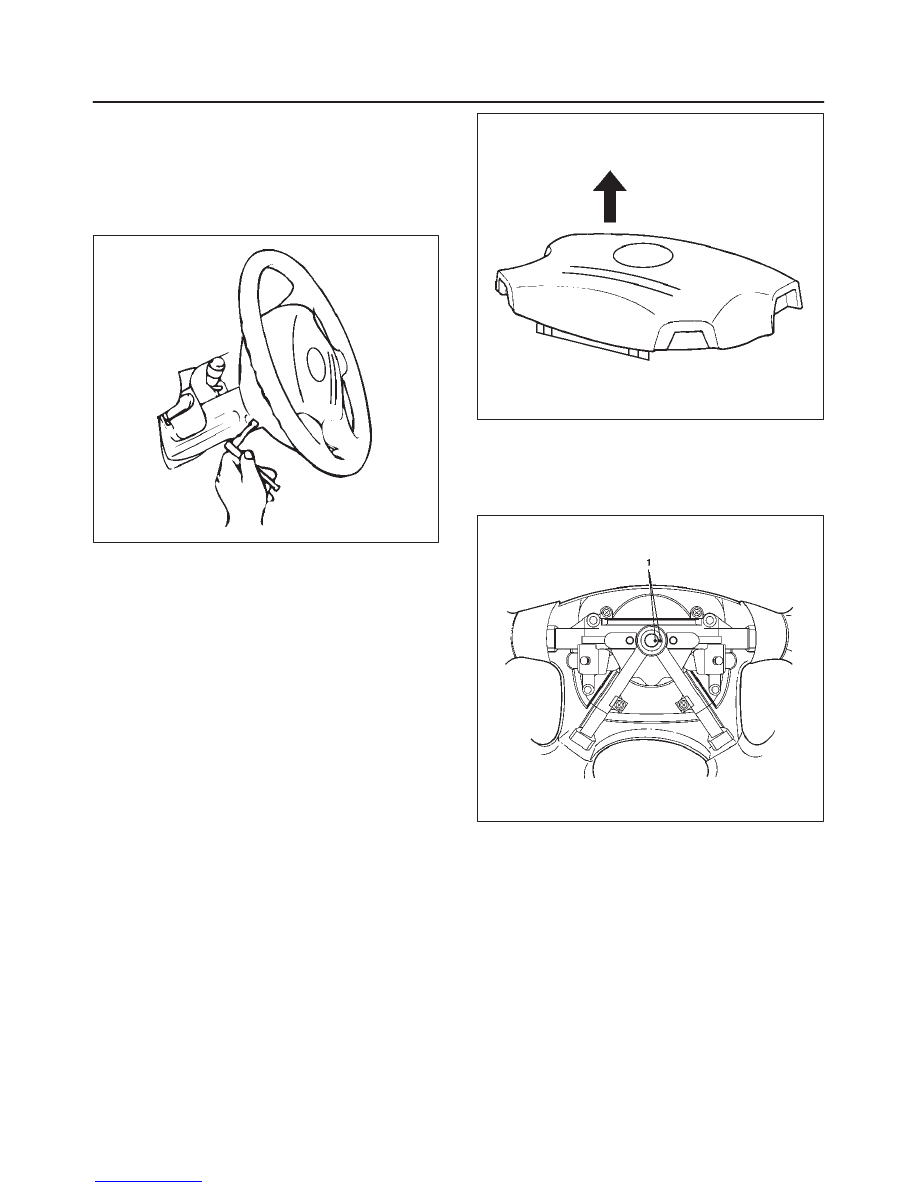

7. Loosen the inflator module fixing bolt from behind the

steering wheel assembly using a TORX

driver or

equivalent until the inflator module can be released

from steering assembly.

827RW070

8. Disconnect the yellow 2-way SRS connector and

horn lead located behind the inflator module.

9. Remove inflator module.

WARNING: THE INFLATOR MODULE SHOULD

ALWAYS BE CARRIED WITH THE URETHANE

COVER AWAY FROM YOUR BODY AND SHOULD

ALWAYS BE LAID ON A FLAT SURFACE WITH THE

URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE A FREE SPACE IS PROVIDED TO ALLOW

THE AIR CUSHION TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT.

OTHERWISE, PERSONAL INJURY MAY RESULT.

827RW072

10. Apply a setting mark (1) across the steering wheel

and shaft so parts can be reassembled in their original

position. Move the front wheels to the straight ahead

position, then use steering wheel remover J–29752

to remove the steering wheel.

430RW021