Isuzu KB P190. Manual - part 636

Engine Mechanical – V6

Page 6A1–65

8

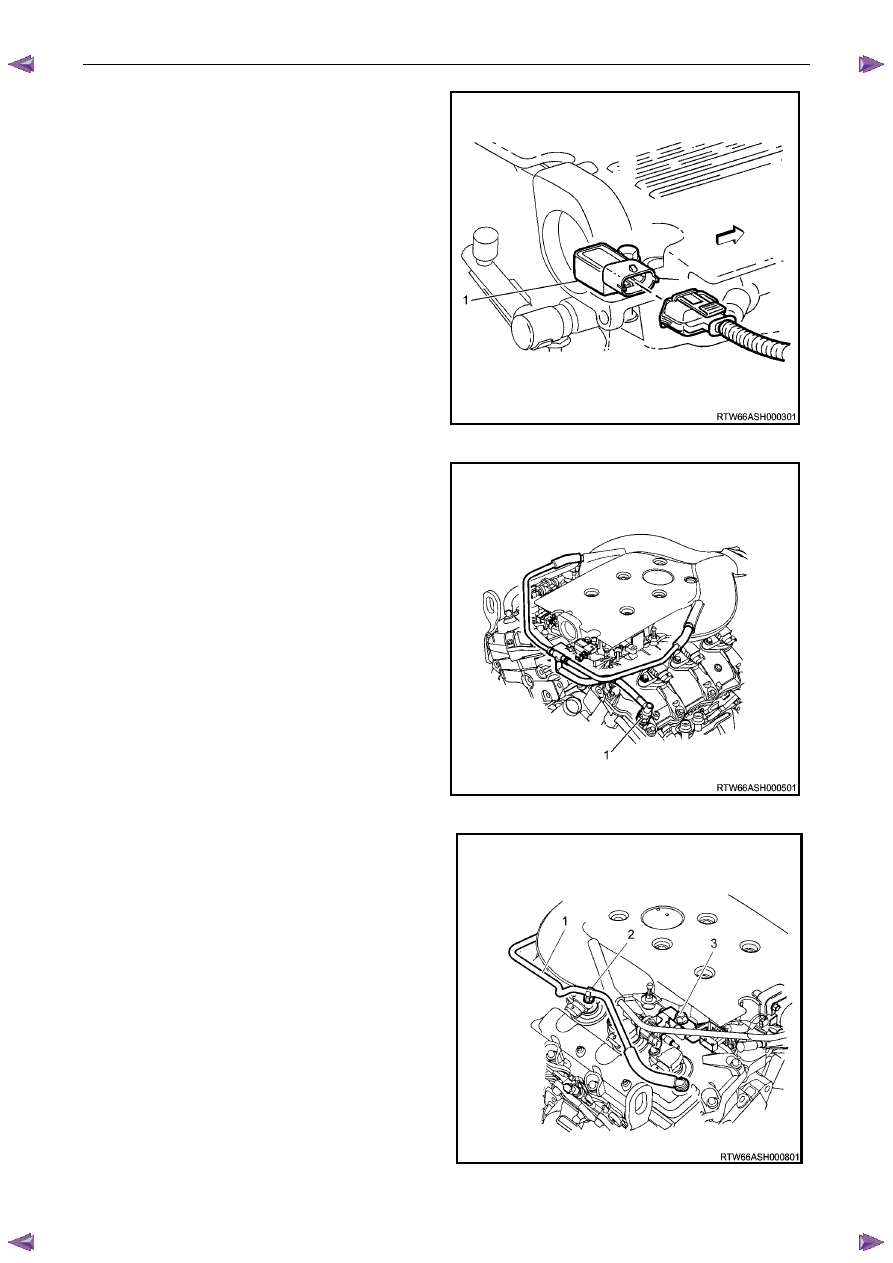

Disconnect the wiring harness connector from the

barometric (BARO) pressure sensor (1).

Figure 6A1 – 37

9

Disconnect the PCV tube connector (1) from the

upper intake manifold assembly.

Figure 6A1 – 38

10

Remove the bolt (3) attaching the EVAP valve and the

fuel injector wiring harness connector mounting

bracket to the upper intake manifold assembly.

11

Move the EVAP valve and the fuel injector wiring

harness connector mounting bracket clear of the upper

intake manifold assembly.

12

Disconnect the PCV fresh air tube (1) from its upper

intake manifold mounting clip (2).

Figure 6A1 – 39