Infiniti G35 (V35). Manual - part 686

RAX-16

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

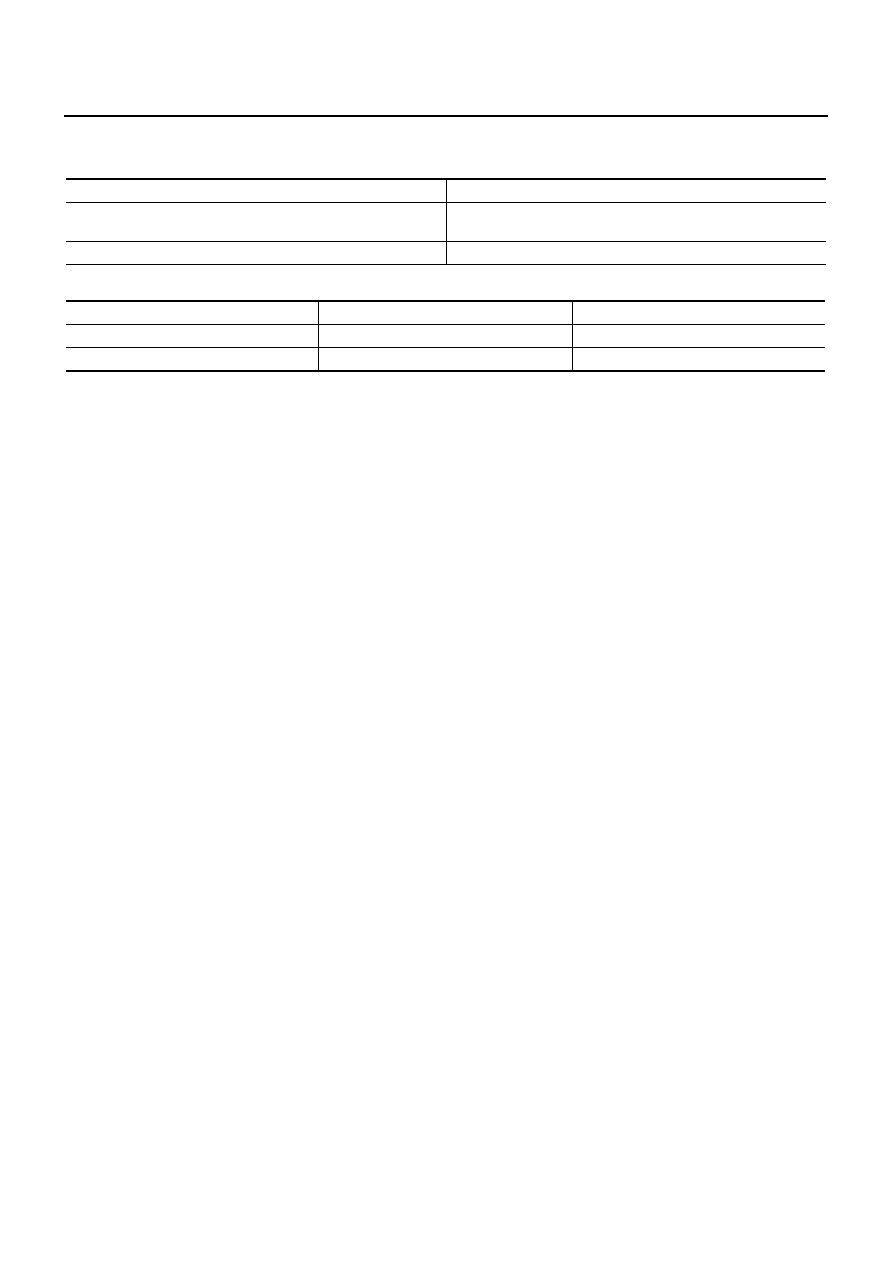

Wheel Bearing

NDS00028

Drive Shaft

NDS00029

Axial end play

0 mm (0 in)

Rotational torque

At a load of 49,033 N (5,000 kg, 11,000 lb)

Less than 1.88 N·m (0.19 kg-m, 17 in-lb)

Measurement of spring balance

Less than 18.5 N (1.89 kg, 4.16 lb)

Joint

Wheel side

Final drive side

Grease quantity

86 – 96 g (3.03 – 3.39 oz)

124 – 134 g (4.37 – 4.73 oz)

Boots installed length

97.0 mm (3.819 in)

93.9 mm (3.697 in)