Infiniti G35 (V35). Manual - part 678

PS-22

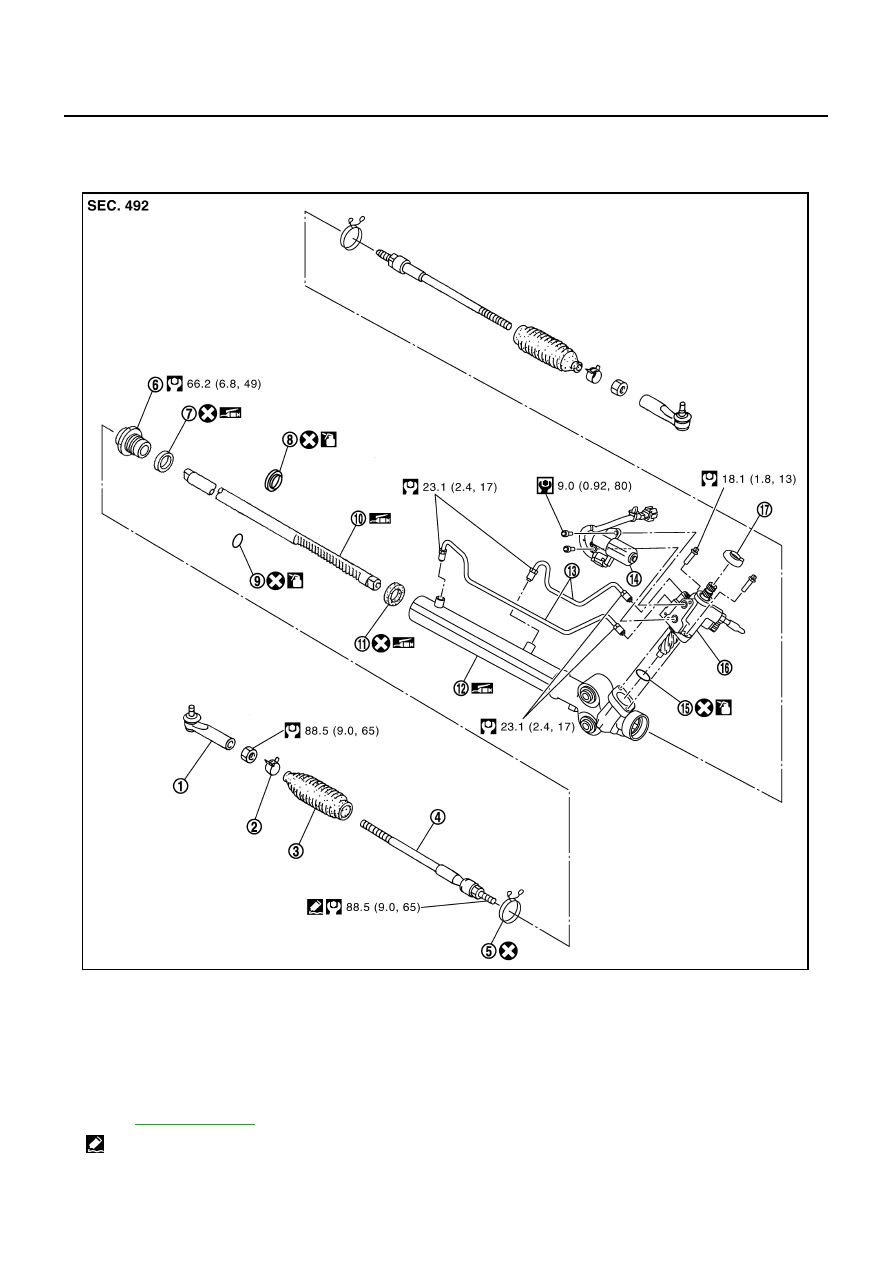

POWER STEERING GEAR

POWER STEERING GEAR

PFP:49001

Disassembly and Assembly

NGS000BH

COMPONENTS

1.

Outer socket

2.

Boot clamp

3.

Boot

4.

Inner socket

5.

Boot clamp

6.

End cover assembly

7.

Rack oil seal

8.

Rack Teflon ring

9.

O-ring

10. Rack assembly

11.

Rack oil seal

12. Gear housing assembly

13. Cylinder tubes

14. Power steering solenoid valve

(with EPS)

15. O-ring

16. Gear sub-assembly

17. Rear cover cap

, and the followings for the symbols in the figure.

: Apply Genuine Thread Locking Sealant, Three Bound 1111B or equivalent.

SGIA1476E