Hyundai Santa Fe (2006 year). Manual - part 503

FLA -78

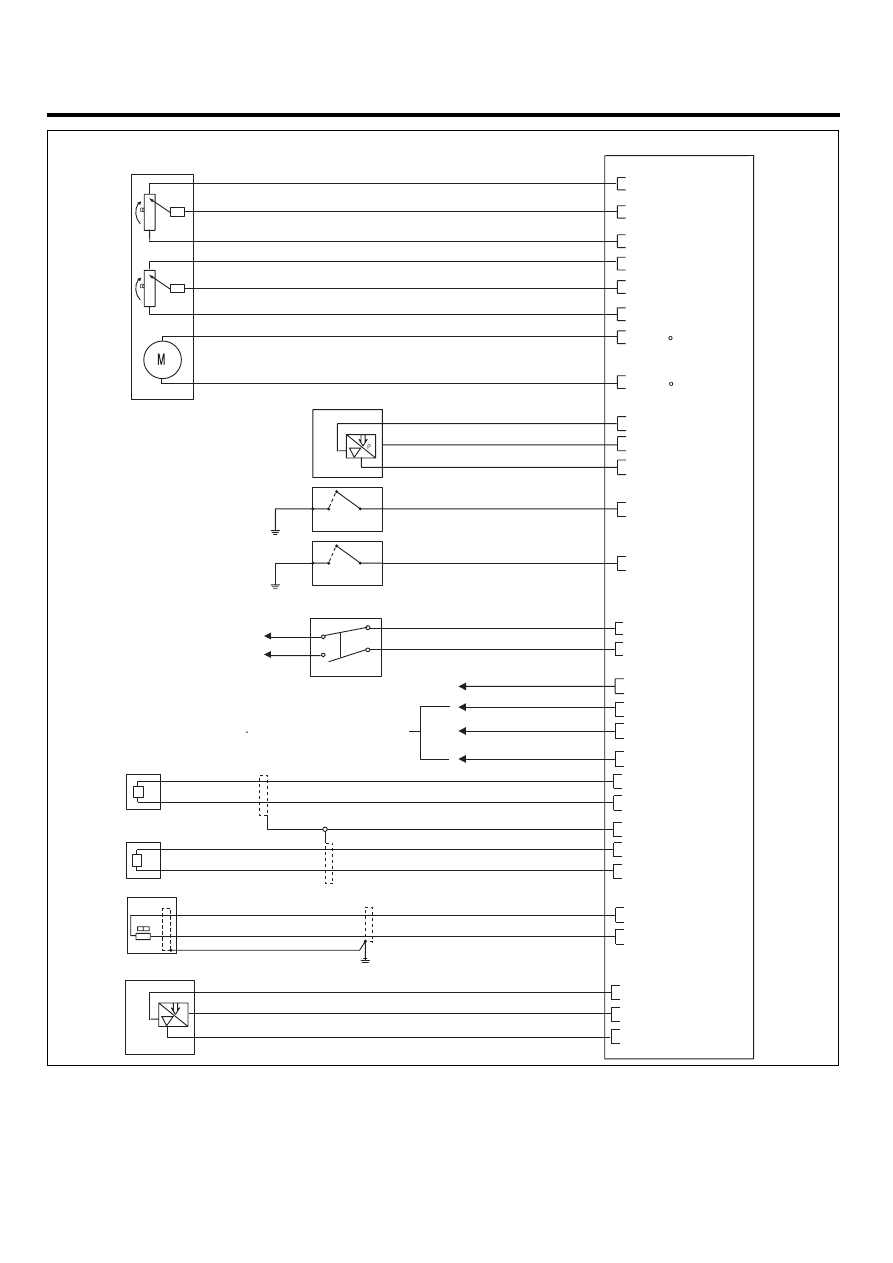

FUEL SYSTEM

P C M

B16 - Reference voltage (+5V)

B13 - Reference voltage (+5V)

B48 - TPS1 signal input

B14 - Sensor ground

B57 - TPS2 signal input

B58 - Sensor ground

B2 - ETC Mot r (+) control

B1 - ETC Mot r (-) control

A33 - Sensor ground

A58 - Reference voltage (+5V)

A32 - Sensor signal input

A10 - Power Steering Pressure

Switch signal input

A23 - Brake lamp signal input

A21 - Brake switch signal input

A15 - Alternator load signal input

A26 - A/C blower switch signal input

A64 - A/C compressor relay control

A18 - A/C switch "ON" signal input

B55 - KS [Bank 1] [LOW] signal input

B54 - KS [Bank 2] [LOW] signal input

B56 - KS [Bank 1] [HIGH] signal input

B53 - KS [Bank 2] [HIGH] signal input

B21 - CKPS [HIGH] signal input

B41 - CKPS [LOW] signal input

B34 - Sensor ground

B8 - MAPS signal input

B11 - Reference voltage (+5V)

B23 - Sensor shield

ETC MODULE

4

2

1

7

3

6

5

8

TPS2

TPS1

ETC MOTOR

A/C PREESSURE SENSOR

BRAKE SWITCH

ALTERNATOR

Refer to "Electrical Troubleshooting Manual"

KS [BANK 1]

KS [BANK 2]

CKPS

MAPS

Battery(+)

IG ON

2

1

3

4

1

3

2

P

1

2

1

2

3

1

4

2

2

1

S

N

POWER STEERING

PRESSURE SWITCH

A13 - Clutch Switch signal input

CLUCH SWITCH

SCMF16129L