Hummer H2. Manual - part 78

CALIPERS

You are not required to replace or rebuild calipers in axle sets. However, when replacing or rebuilding a caliper

due to the conditions that follow, you may suggest servicing, rebuilding, or replacement of the other caliper (on

the same axle) for improved performance and preventive maintenance (for example, the part is close to the end

of its useful life, replacing the caliper may extend pad life, or contribute to more balanced braking).

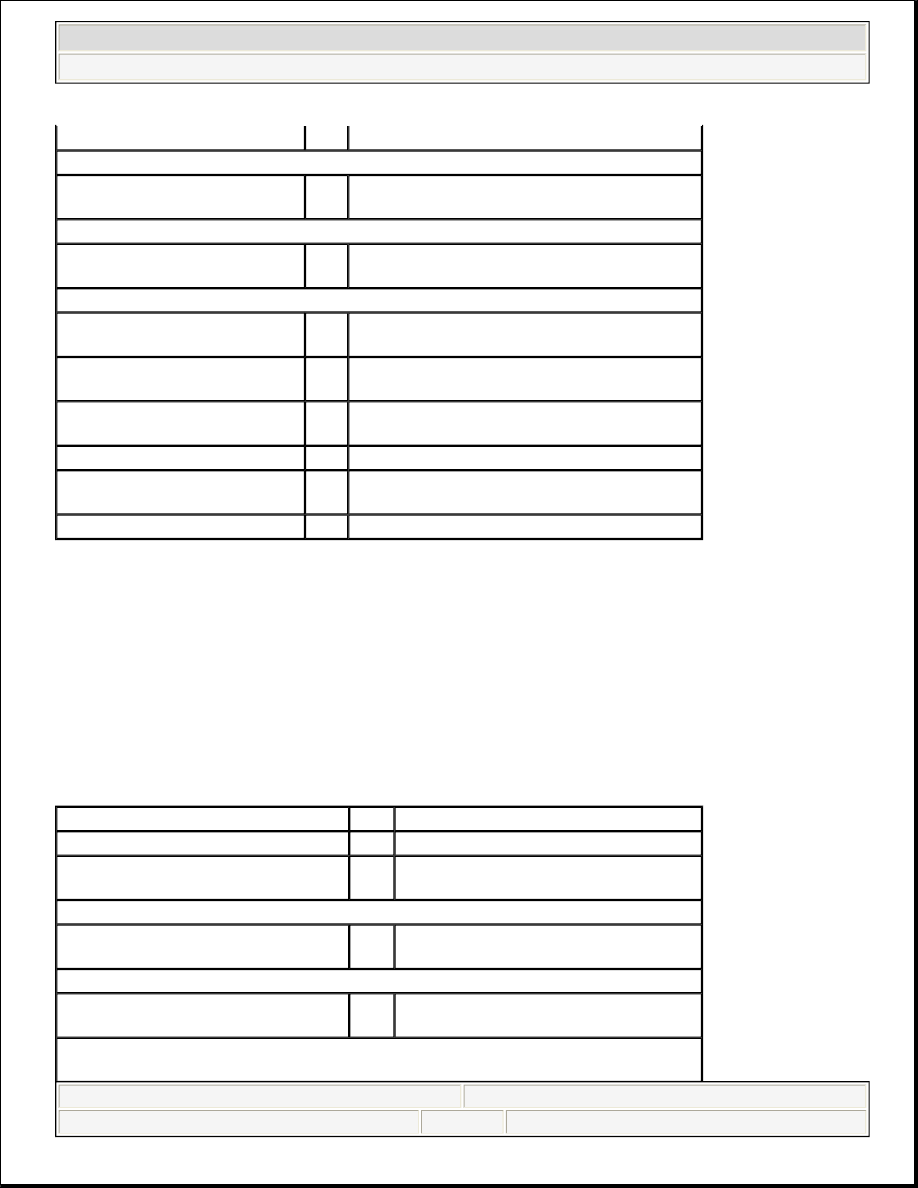

Calipers

Shim (OE standard) missing

C

Require replacement. See note below.

NOTE: Aftermarket shims may be suggested to reduce noise.

Shim out of position

B

Require removal or replacement. See note

below.

NOTE: Removal is acceptable if shim is not OE.

Shim worn

A

Require removal or replacement. See note

below.

NOTE: Removal is acceptable if shim is not OE.

Slider pin (bolt) bent

B

Require replacement of slider pin or bolt and

lubricants.

Slider pin (bolt) rust-pitted

A

Require replacement of slider pin or bolt and

lubricants.

Slider pin (bolt) worn

A

Require replacement of slider pin or bolt and

lubricants.

Threads damaged

A

Require repair or replacement.

Threads stripped (threads

missing)

A

Require replacement.

Worn, affecting performance

A

Require replacement.

CAUTION: When installing loaded calipers, it is required that friction material be

matched in axle sets for consistent braking characteristics.

Condition

Code

Procedure

Bleeder port damaged

A

Require repair or replacement of caliper.

Bleeder screw broken off in caliper

A

Require repair or replacement of caliper.

See note below.

NOTE: Only required if the hydraulic system must be opened.

Bleeder screw plugged

A

Require repair or replacement of bleeder

screw. See note below.

NOTE: Only required if the hydraulic system must be opened.

Bleeder screw seized

A

Require replacement of caliper. See note

below.

NOTE: Seized is defined as a bleeder screw that cannot be removed after a practical

attempt at removing. Only required if the hydraulic system must be opened.

1998 Chevrolet Pickup C1500

Uniform Inspection and Communication Standards BRAKE SYSTEMS