Hummer H2. Manual - part 68

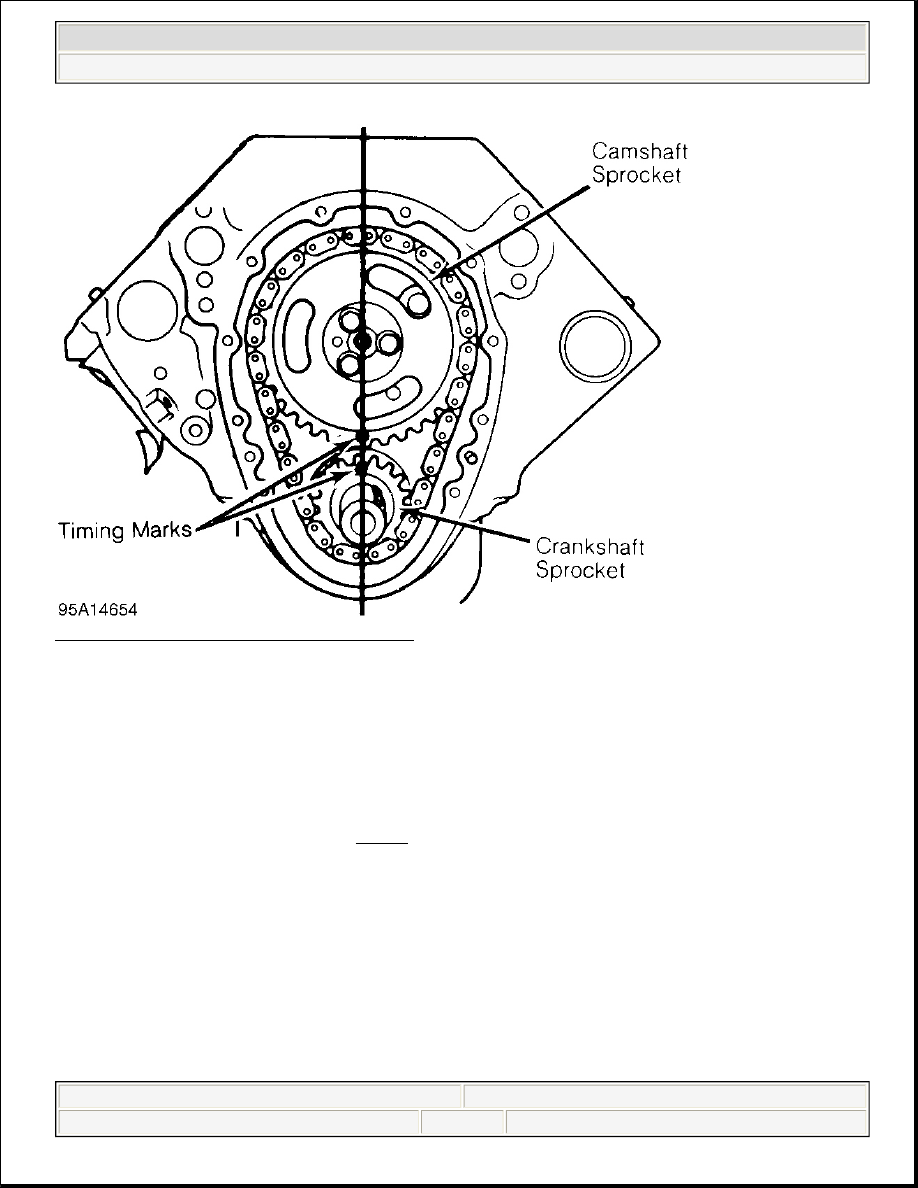

Fig. 24: Typical Gear Timing Mark Alignment

TIMING BELTS

Cogged tooth belts are commonly used on overhead cam engines. Inspect belt teeth for rounded corners or

cracking. Replace belt if it is cracked, damaged, missing teeth or oil soaked.

Used timing belt must be installed in original direction of rotation. Inspect all sprocket teeth for wear. Replace

all worn sprockets. Sprockets are marked for timing purposes. Engine is positioned so that crankshaft sprocket

mark will be upward. Camshaft sprocket is aligned with reference mark on cylinder head or timing belt cover

and then timing belt can be installed. See Fig. 25 .

1998 Chevrolet Pickup C1500

GENERAL INFORMATION Engine Overhaul Procedures