Hummer H2. Manual - part 66

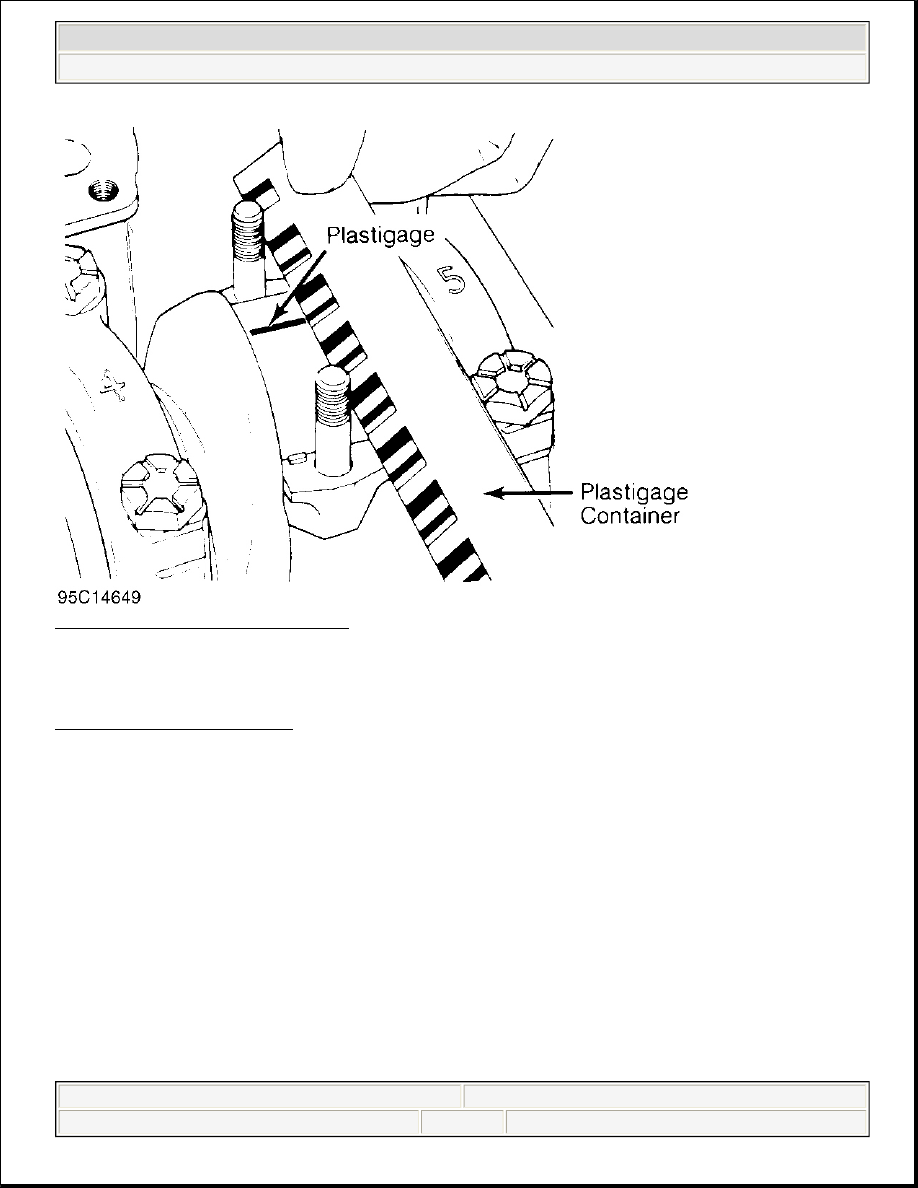

Fig. 19: Measuring Bearing Clearance

Micrometer & Telescopic Gauge Method

A micrometer is used to determine journal diameter, taper and out-of-round dimensions of the crankshaft. See

CLEANING & INSPECTION under CRANKSHAFT & MAIN BEARINGS in this article.

With crankshaft removed, install bearings and caps in original location on cylinder block. Tighten bolts to

specification. On connecting rods, install bearings and caps on connecting rods. Install proper connecting rod

cap on corresponding rod. Ensure bearing cap is installed in original location. Tighten bolts to specification.

Using a telescopic gauge and micrometer or inside micrometer, measure inside diameter of connecting rod and

main bearings bores. Subtract each crankshaft journal diameter from the corresponding inside bearing bore

diameter. This is the bearing clearance.

CRANKSHAFT & MAIN BEARINGS

REMOVAL

Ensure all main bearing caps are marked for location on cylinder block. Some main bearing caps have an arrow

stamped on them. The arrow must face timing belt or timing chain end of engine. Remove main bearing cap

bolts. Remove main bearing caps. Carefully remove crankshaft. Use care not to bind crankshaft in cylinder

block during removal.

1998 Chevrolet Pickup C1500

GENERAL INFORMATION Engine Overhaul Procedures