Hummer H1 (2002+). Manual - part 259

____________________________________________________________

Accessories 13-29

®

05745159

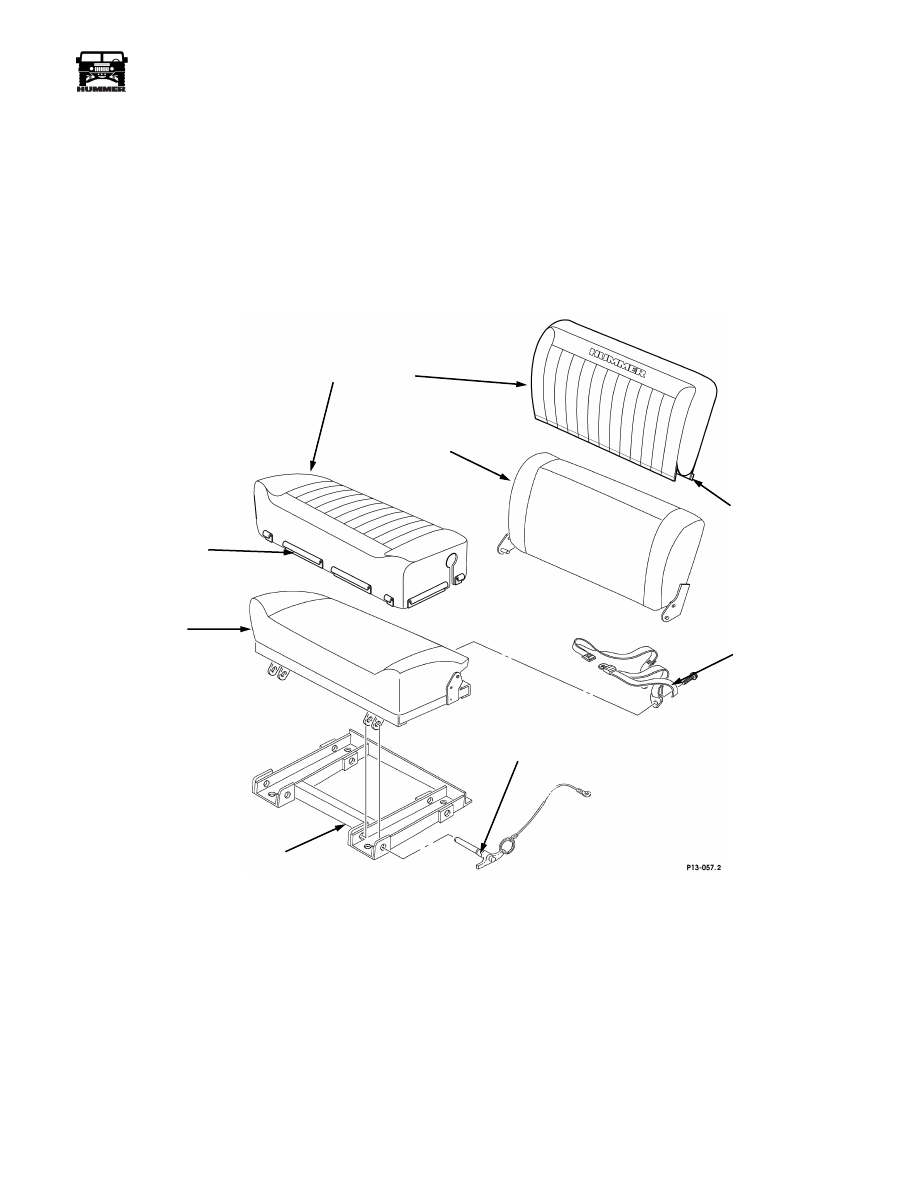

UPHOLSTERY, LEATHER AUXILIARY SEAT

Removal

1.

Remove the four locking pins securing the auxiliary seat to

the seat frame (See Figure 13-63).

2.

Remove the auxiliary seat from the seat frame.

3.

Seat Base:

a.

Remove the bolts securing the safety belts to the rear

of the auxiliary seat cushion frame.

b.

Remove the safety belts from the auxiliary seat

cushion frame.

c.

Release the plastic “J” retainers from the seat cushion

frame and remove the fabric from the seat cushion.

4.

Seat Back:

a.

Release the hook and loop securing the front portion

of the fabric to the rear fabric at the bottom of the seat

back.

b.

Pull the fabric upward and remove it from the seat

back.

Figure 13-63: Auxiliary Seat Cover Installation.

Installation

1.

Seat Base:

a.

Using the original fabric as a template, mark and cut

the leather seat cushion upholstery for the safety belt

mounting hardware.

b.

Position the leather on the seat cushion and secure the

plastic “J” retainers to the seat cushion frame.

c.

Install the safety belts through the leather upholstery

into the seat frame and torque the fasteners to 72-78

lb-ft (98-106 N•m).

2.

Seat Back:

a.

Slide the leather upholstery down onto the seat back

and secure the hook and loop at the bottom of the seat

back.

3.

Install the auxiliary seat on the seat frame and secure with

the four locking pins.

CAUTION:

Locking pins must be fully inserted into the seat

frame. The balls near the end of the pins must be visible at the

inboard side of the seat frame bracket.

SEAT

BACK

SEAT

CUSHION

SAFETY

BELT

SEAT

FRAME

LOCKING

PIN

PLASTIC

“J” RETAINER

HOOK

LEATHER

UPHOLSTERY

AND LOOP