Hummer H1 (2002+). Manual - part 109

______________

Wheels and Tires/Central Tire Inflation System (CTIS) 6-51

®

05745159

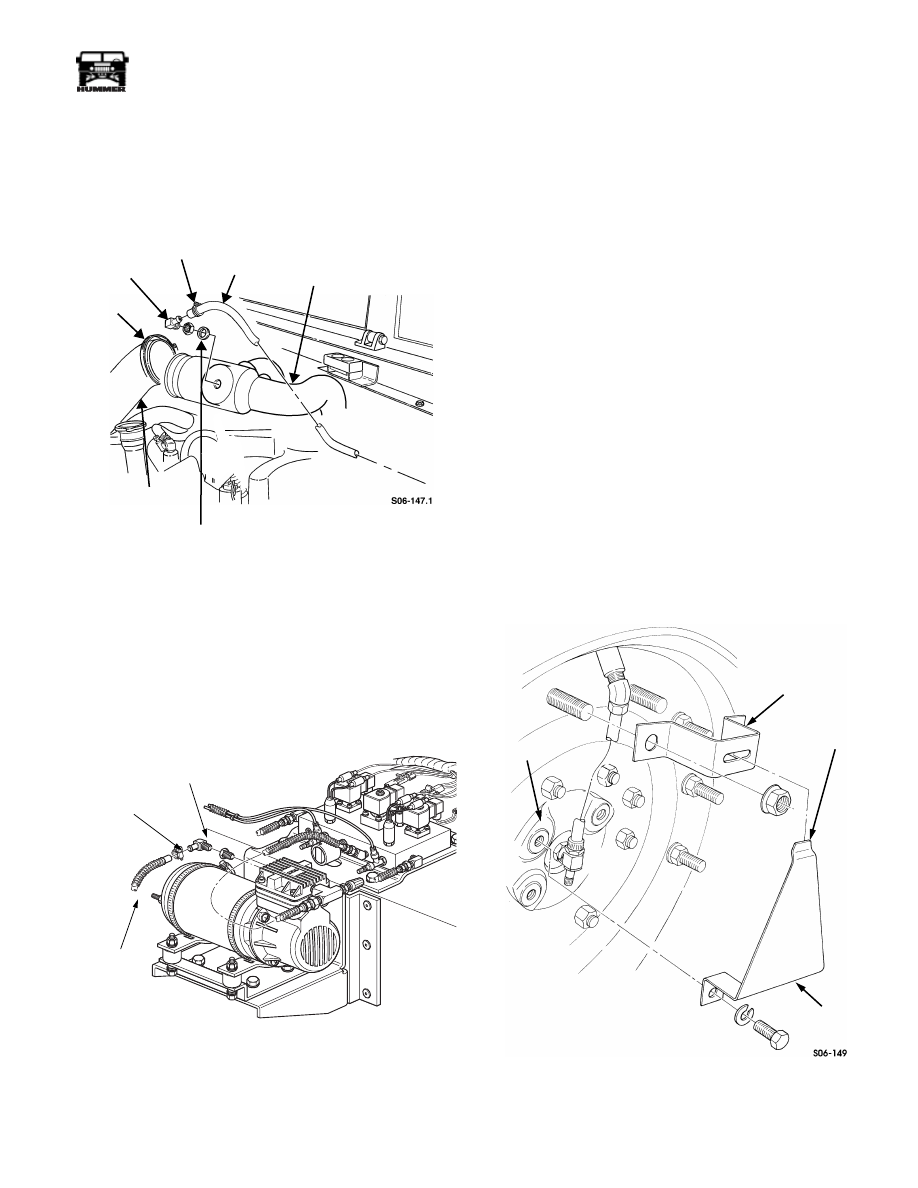

AIR INTAKE LINE REPLACEMENT

Removal

1.

Raise and secure hood.

2.

Loosen hose clamp and disconnect air intake hose from

connector (Figure 6-73).

Figure 6-73: Air Intake Hose

3.

Loosen clamp and disconnect air cleaner elbow from air

horn.

4.

Remove nut, washer, coupling, connector, and seal from

air horn.

5.

Loosen hose clamp securing air intake hose to compressor

fitting (Figure 6-74).

Figure 6-74: Air Intake Hose to Fitting

6.

Remove air intake hose.

Cleaning and Inspection

Clean and inspect air intake hose, elbow, coupling assembly

and seal. Check for leaks, cracks, and stripped threads.

CAUTION: Do not allow sealant into air system. Sealant will

damage CTIS components.

NOTE: Apply sealant to threads prior to installation.

Installation

1.

Connect air intake hose to compressor fitting and secure

with hose clamp (Figure 6-74).

2.

Install seal, coupling, washer, nut, and connector to air

horn (Figure 6-73).

3.

Connect air cleaner elbow to air horn and secure with

clamp.

4.

Connect air intake hose to air horn connector and secure

with hose clamp.

5.

Lower and secure hood.

TUBE SHIELD REPLACEMENT

1.

Remove bolts, washers and tube shield from wheel.

2.

Install new CTIS decal on tube shield, if necessary.

3.

Install tube shield tab into slot on bracket.

4.

Secure tube shield to spindle with bolts and washers.

Figure 6-75: Tube Shield Assembly

AIR

INTAKE

HOSE

AIR

HORN

SEAL

ELBOW

CLAMP

CONNECTOR

CLAMP

9-S06-012

CLAMP

FITTING

AIR INTAKE

HOSE

TAB

TUBE SHIELD

SPINDLE

BRACKET