Hummer H1 (2002+). Manual - part 21

____________________________________________________________________

Engine 2-45

®

05745159

OVERHAUL SERVICE INFORMATION

Anaerobic and RTV type sealers are both used during engine

re-assembly. Anaerobic sealer such as Loctite gasket maker

(515 or 510) is used on the timing chain cover. RTV sealers

such as Permatex Ultra Copper, Ultra Blue, or Loctite 599, are

used on the oil pan and rocker covers.

Thread locking chemicals such as Loctite 242 are specified

wherever necessary. In addition, Permatex dielectric com-

pound can be used on electrical connections to prevent corro-

sion.

Do not use substitute fasteners unless they are of the correct

size and hardness grade. When replacement bolts/nuts are re-

quired, it is recommended that parts catalog items be used.

This ensures that correct grade fasteners are used.

ENGINE REMOVAL

1.

Remove front console attaching screws. Move console

rearward and disconnect console harness connector and

radio harness. Then remove console.

2.

Disconnect Digital Ratio Adapter and Keyless Entry

Module. Remove inner engine cover.

3.

Remove hood with aid of helper as follows:

• Unlatch and lower brushguard, if equipped.

• Unlatch and raise hood.

• Remove clip that attaches hood harness to driver side of

frame.

• Disconnect hood harness from cowl top harness.

• Remove bolts attaching prop and bracket to driver side

air lift bracket. Do not remove prop rod from hood.

Leave rod attached. Tape rod to hood if desired.

• Remove hood hinge pins.

• Remove hood with aid of helper.

4.

Disconnect and remove batteries and cables.

5.

Remove battery tray.

6.

Remove driver and passenger side splash shields.

7.

Drain engine coolant and engine oil.

8.

Discharge A/C system with recovery machine set in

recovery mode.

9.

Disconnect radiator upper and lower hoses at the radiator.

10. Drain fluid in power steering pump using a suction gun.

11. Disconnect oil lines at transmission and power steering

coolers. Cap lines to prevent dirt entry Figure 2-52.

12. Disconnect engine cooler lines for engine oil cooler. Cap

lines to prevent dirt entry.

13. Disconnect A/C lines at condenser. Cap or tape lines and

fittings to prevent dirt entry.

14. Remove rubber/sponge pads from air lift brackets.

15. Remove return hoses from power steering pump.

16. Remove surge tank hose from radiator.

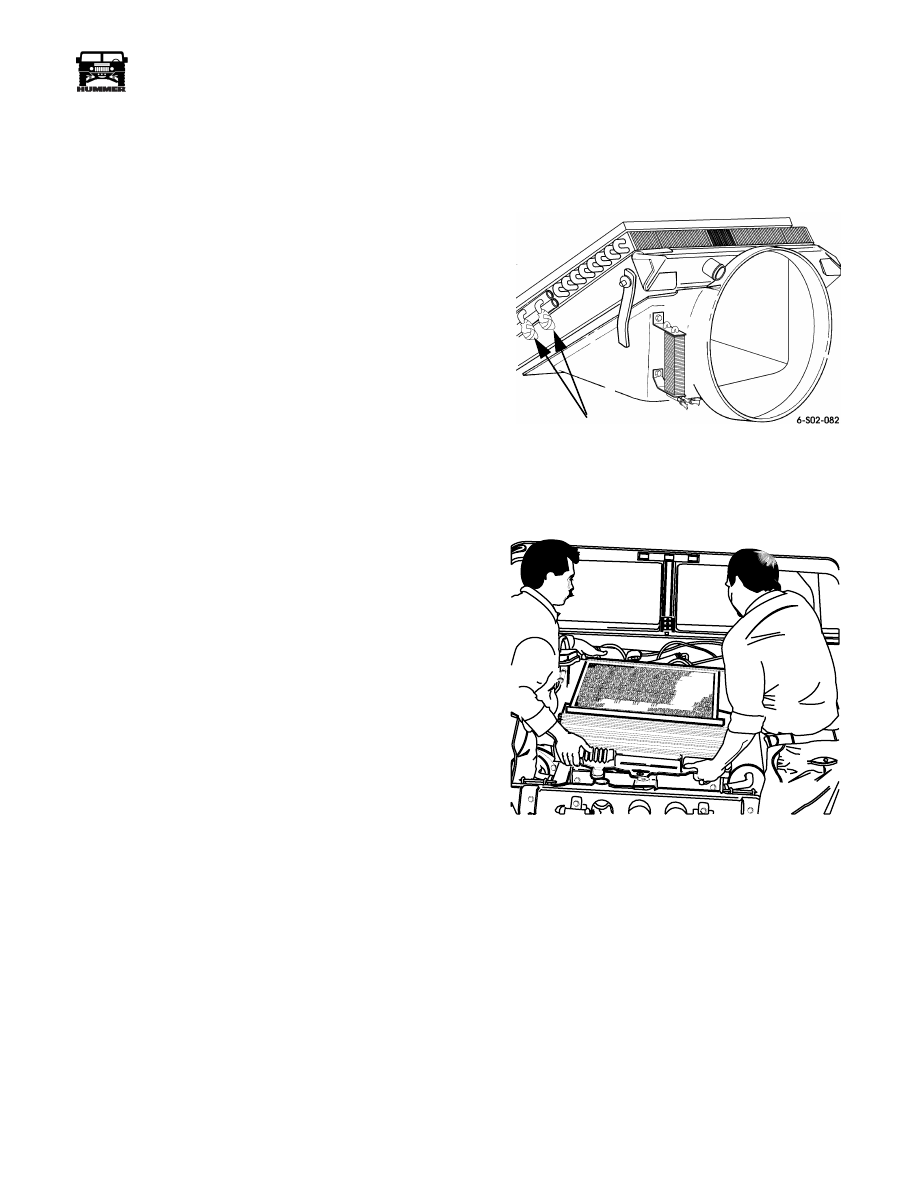

17. Remove bolts attaching radiator and shroud assembly to

frame and brackets. Then (with aid of helper), remove

radiator, shroud, condenser, and oil coolers as an assembly

Figure 2-53.

.

Figure 2-52: Covering Open Ends of Oil

Cooler Lines

Figure 2-53: Radiator, Cooler, Fan Shroud

Removal/Installation

18. Remove air horn from turbocharger and air cleaner hose

(Figure 2-54).

19. Disconnect radiator hose at thermostat housing and at

radiator upper and lower outlets.

20. Remove the engine oil dipstick and tube

21. Loosen tensioner and remove serpentine belt.

22. Using the spanner wrench and ratchet adapter, remove

cooling fan and clutch from water pump.

COVER OPEN ENDS

OF ALL COOLER LINES

WITH DUCT TAPE

6-S02-009