содержание .. 200 201 202 203 204 ..

Geely EC718, EC718RV, EC715, EC715RV. Manual part - 203

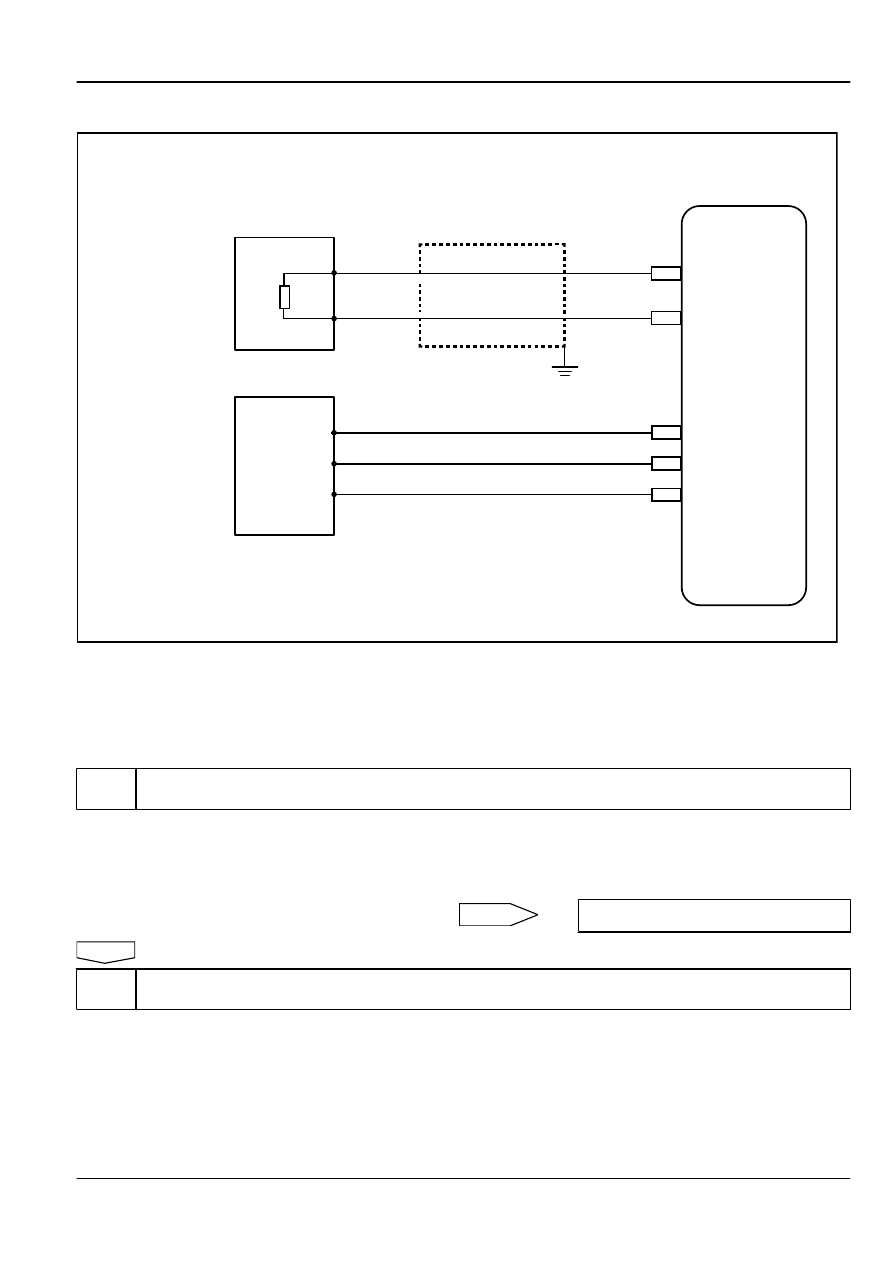

3. Schematic:

CPS HI

CPS LO

21

20

EO01

EO01

A

B

B

A

C

EO01

EO01

EO01

18

56

23

V5RTN2

CAM1

V5REF2

Crankshaft Position Sensor

Camshaft Position Sensor

Engine

Control

Module

FE02-5297b

4. Diagnostic Steps:

Note

Before carrying out this diagnosis step, observe the data list on scan tool and analyze the accuracy of the data, as

these will help with quick diagnosis.

Step 1

Initial Inspection

(a)

Check the sensor wiring harness connector EN26 whether

there is loose or poor connection and so on.

(b)

Check whether the sensor is installed correctly.

(c)

Check whether the sensor gap is normal.

No

Repair the faulty part. Go to step 10

Yes

Step 2

Read the engine data (engine speed) on the scan tool.

(a)

Connect scan tool to datalink connector.

(b)

Turn the ignition switch to "ON" position.

(c)

Select "Engine"/"Reading Data"/"Engine Speed."

(d)

Start the engine.

(e)

With the engine running, read the engine data on the scan

tool

Engine

Control System JL4G15-D

2-727