содержание .. 18 19 20 21 22 23 24 25 ..

Geely EC718, EC718RV, EC715, EC715RV. Manual part - 24

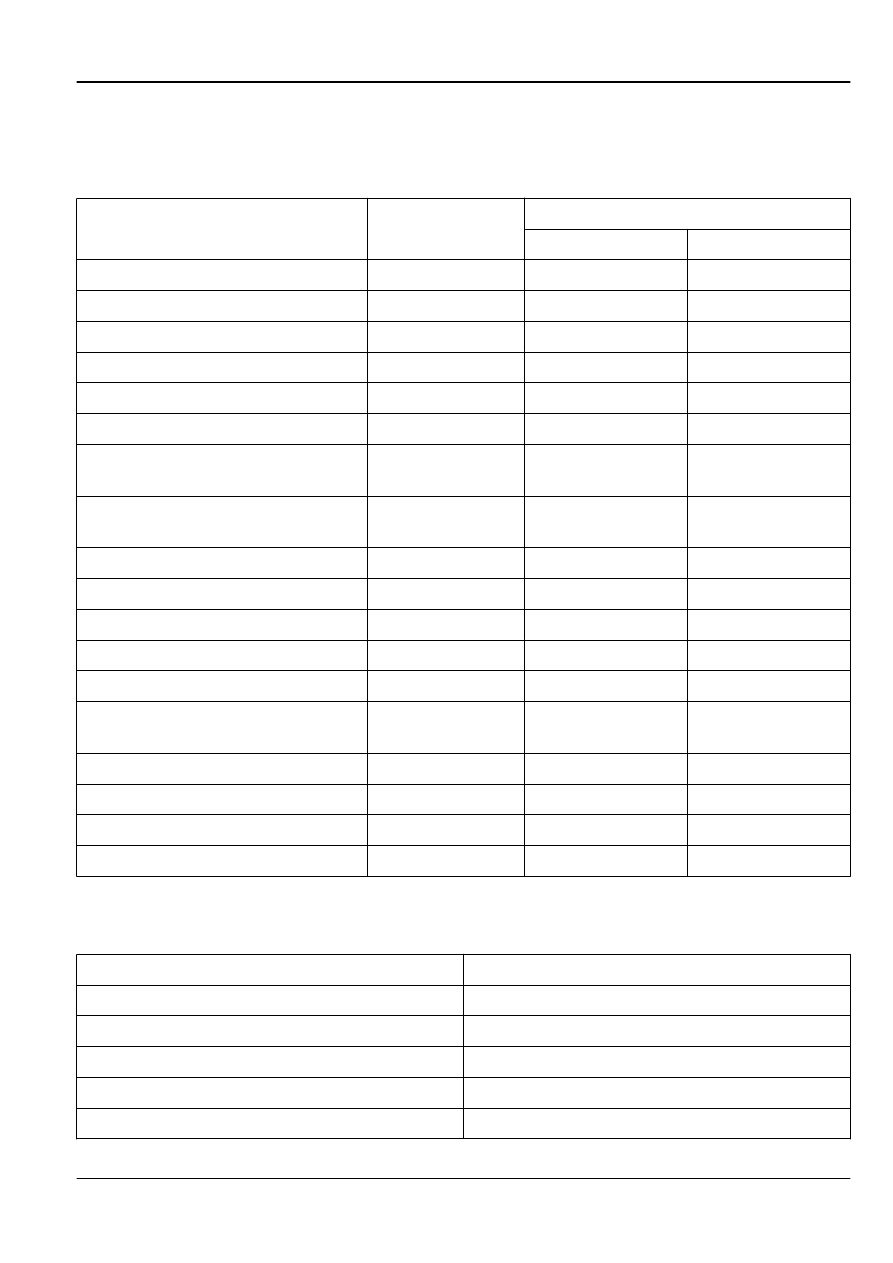

2.2 Control System JL4G18-D

2.2.1 Specifications

2.2.1.1 Fastener Tightening Specifications

Applications

Model

Specifications

Metric (Nm)

US English (lb-ft)

Camshaft Position Sensor Retaining Bolts

M6X14

8-10

6.0-7.4

Crankshaft Position Sensor Retaining Bolts

M6X12

8-10

6.0-7.4

Ignition Coil Retaining Bolts

M6X35

7-11

5.2-7.8

Engine Control Module Retaining Bolts

M6X16

8-10

6.0-7.4

Engine Coolant Temperature Sensor Bolts

M12 × 1.5 × 6

15

11

Evaporative Emissions Canister

M6X20

7-9

5.2-6.7

Evaporative Emissions Canister Solenoid Valve

Bracket Retaining Bolts

M6X20

7-9

5.2-6.7

Fuel Filter Mounting Bracket Assembly

Retaining Bolts

M6X16

8-10

6.0-7.4

Fuel Filter Mounting Bracket Retaining Bolts

M6X16

8-10

6.0-7.4

Fuel Rail Retaining Bolts

M6X20

10

7

Fuel Tank Retaining Bolts

M10X30

38-46

28.1-34.0

Idle Air Control Valve Retaining Bolts

M4X10

2-3

1.5-2.2

Knock Sensor Retaining Bolts

M8X30

15-22

10.7-16.0

Intake Manifold Absolute Pressure and

Temperature Sensor Retaining Bolts

M6X12

8-10

6.0-7.4

Oxygen Sensor Retaining Bolts

M18X8

44

32.6

Air-Conditioning Compressor Mounting Bolts

M8X80

25

18.2

Spark Plug Retaining Bolts

M14 × 1.25 × 22

20-30

14.8-22.2

Throttle Body Retaining Bolts

M8

20-25

14.8-18.5

2.2.1.2 Temperature Sensor Temperature and

Resistance Correlation

Temperature (°C) / ( ºF)

Resistance (Ω)

-30/-22

26,000

-25/-13

19,000

-20/-4

15,000

-15/5

11,800

-10/14

9,000

Engine

Control System JL4G18-D

2-11