Dodge Nitro. Manual - part 68

ENGINE OIL LEAK INSPECTION

Begin with a thorough visual inspection of the engine, particularly at the area of the suspected leak. If an oil

leak source is not readily identifiable, the following steps should be followed:

1. Do not clean or degrease the engine at this time because some solvents may cause rubber to swell,

temporarily stopping the leak.

2. Add an oil soluble dye (use as recommended by manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil level indicator to make sure the dye is thoroughly mixed as

indicated with a bright yellow color under a black light.

3. Using a black light, inspect the entire engine for fluorescent dye, particularly at the suspected area of oil

leak. If the oil leak is found and identified, repair as necessary.

4. If dye is not observed, drive the vehicle at various speeds for approximately 24 km (15 miles), and repeat

inspection.

5. If the oil leak source is not positively identified at this time , proceed with the AIR LEAK

DETECTION TEST METHOD as follows:

Disconnect the fresh air hose (make-up air) at the cylinder head cover and plug or cap the nipple on

the cover.

Remove the PCV valve hose from the cylinder head cover. Cap or plug the PCV valve nipple on

the cover.

Attach an air hose with pressure gauge and regulator to the oil level indicator tube.

Gradually apply air pressure from 1 psi to 2.5 psi maximum while applying soapy water at the

suspected source. Adjust the regulator to the suitable test pressure that provides the best bubbles

which will pinpoint the leak source. If the oil leak is detected and identified, repair per service

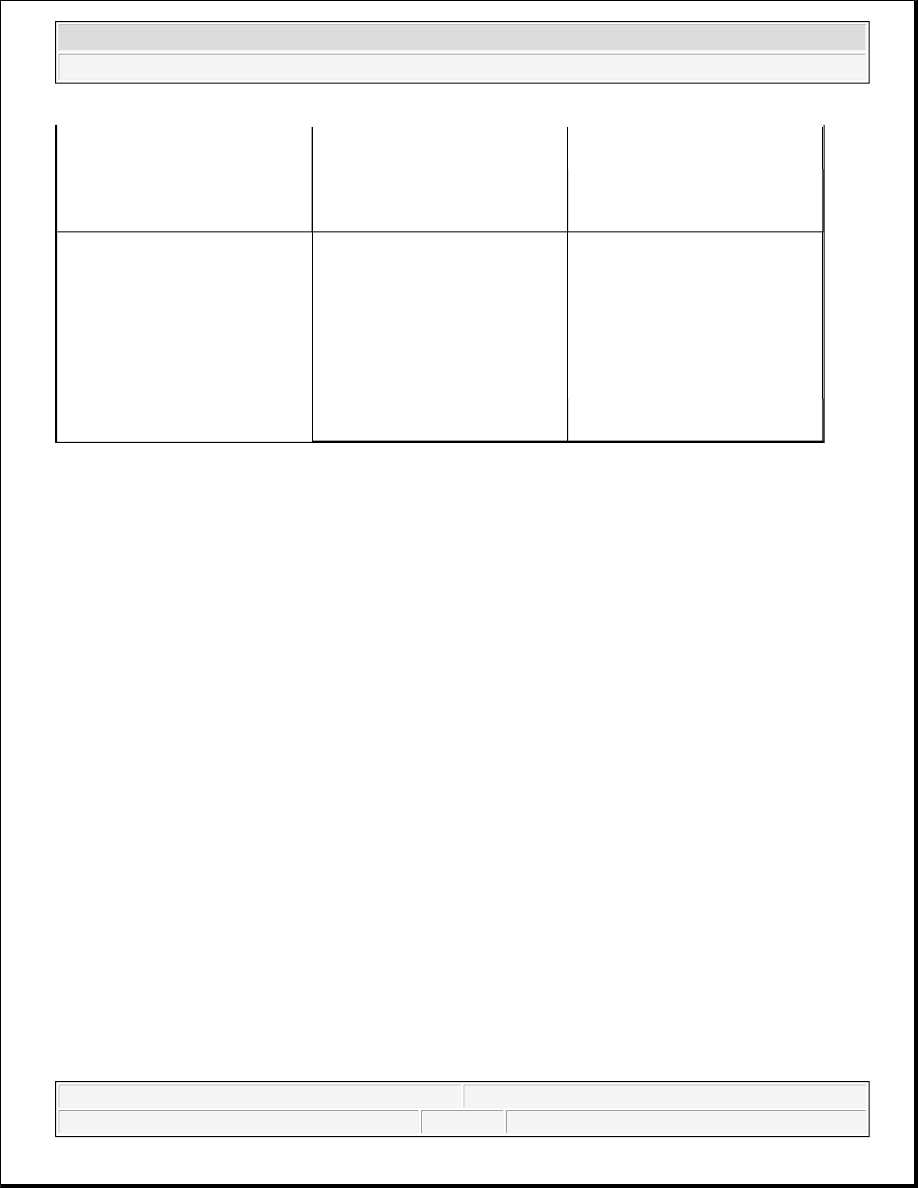

3. Burned, warped, or pitted

valves.

3. Replace valves.

4. Faulty coil(s).

4. Test and replace as necessary.

(Refer to Appropriate Diagnostic

Information)

ENGINE MISSES AT HIGH

SPEED

1. Dirty or incorrect spark plug

gap.

1. Set gap as needed or replace

plug(s).

2. Faulty coil(s).

2. Test and replace as necessary.

(Refer to Appropriate Diagnostic

Information)

3. Dirty fuel injector(s).

3. Test and replace as necessary.

(Refer to Appropriate Diagnostic

Information)

4. Contamination in fuel system.

4. Clean system and replace fuel

filter.

CAUTION: Do not subject the engine assembly to more than 20.6 kpa (3

PSI) of test pressure.

2007 Dodge Nitro R/T

2007 ENGINE 4.0L - Service Information - Nitro