Chery B11. Manual - part 86

2.2 Unfixing, fixing or replacement of two rear wheel disc brake linings

Tips: after fixing the brake linings, brake for a couple of times to engage the brake

linings and brake disc closer together.

After replacing the brake linings of the rear axle, please check the brake fluid level. Fill

in brake fluid to “MAX” level if necessary.

The fixing steps are running contrary to the unfixing steps.

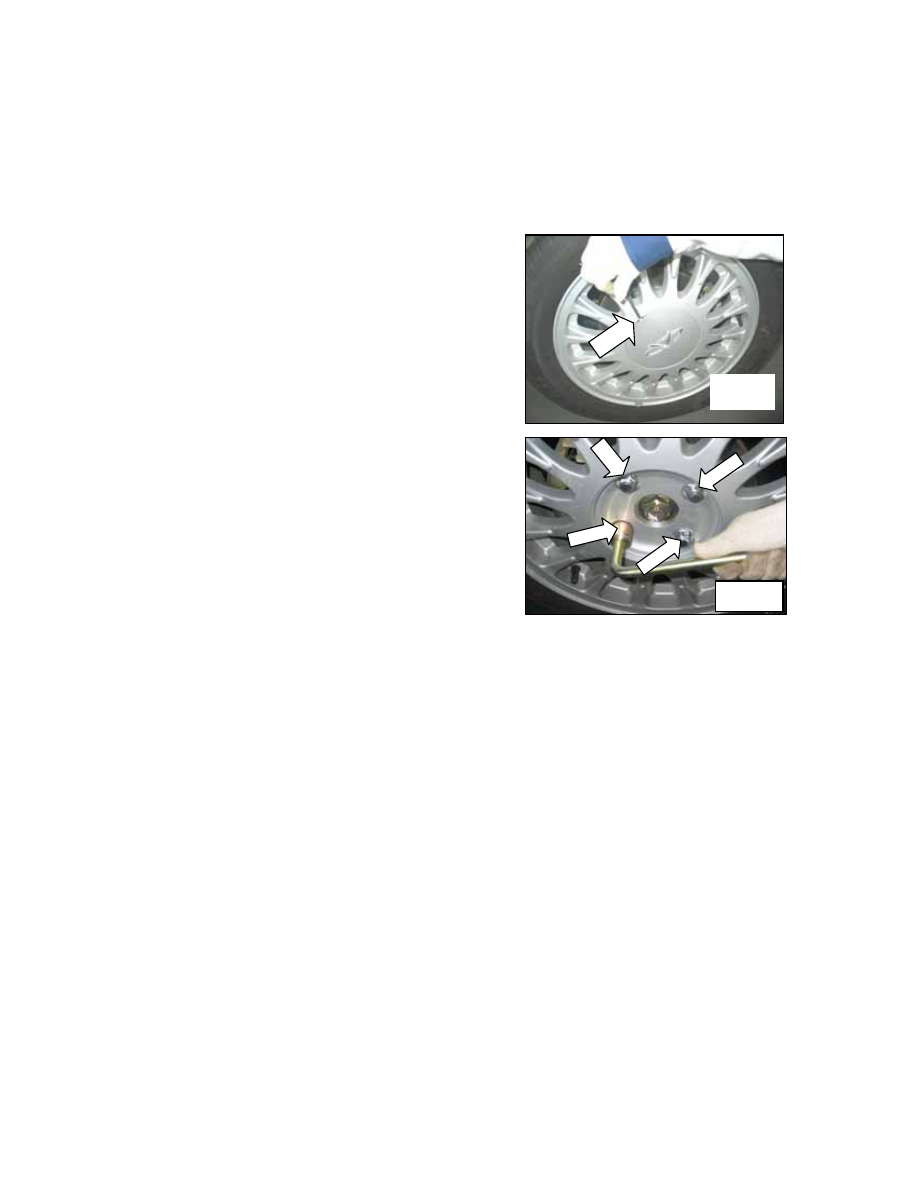

1. Unfix the decorative plate

038

Caution: After having unfixed the decorative

plate, take care not to rub the front of the plate

against the ground to avoid possible scratches.

2. Screw off the four set bolts of the wheels

Screwing torque: 110N.m

Caution: the screwing torque of the tyre bolt

3. Release the guide bolt and pull out the brake

caliper. Do not connect the brake caliper with the

brake hose which may be damaged in that case.

039

Fixing instructions: Only clean the guide bolt but

do not apply grease.

Check the screw thread and replace guide

bolts that are defected. Toss the brake caliper

upwards to dismantle it and then hang it on

metal wires.

4. Dismantle the brake lining

Caution: mark the brake linings that have matched

well. Do not replace the brake linings if only the

brake lining on one side is worn out.

Only when the thickness of brake disc equates or

is less than the minimum thickness (MIIN TH) can

the new brake linings be fixed. Pay attention to

the minimum thickness of brake linings and clean

the brake linings. Do not apply grease on the back

plates of the brake linings.